Home>Production & Technology>Soundproofing>How Much Does Soundproofing A Wall Cost

Soundproofing

How Much Does Soundproofing A Wall Cost

Published: January 26, 2024

Discover the cost of soundproofing a wall and make your space peaceful and quiet. Get expert tips and quotes from professionals in the industry.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for AudioLover.com, at no extra cost. Learn more)

Table of Contents

- Title: How Much Does Soundproofing A Wall Cost

- Introduction

- Factors Influencing Soundproofing Costs

- Wall Material

- Soundproofing Materials

- Wall Size and Thickness

- Wall Condition and Accessibility

- Professional Installation vs. DIY

- Cost Breakdown of Common Soundproofing Options

- Acoustic Panels

- Soundproof Wallpaper

- Soundproof Insulation

- Mass Loaded Vinyl

- Green Glue

- Double Layer Drywall

- Soundproofing Curtains

- Soundproofing Paint

- Soundproofing Foam

- Floating Wall Construction

- Conclusion

Title: How Much Does Soundproofing A Wall Cost

When it comes to creating a peaceful and quiet environment, soundproofing a wall can make a significant difference. Whether you are dealing with noisy neighbors, street traffic, or internal noise within your own space, soundproofing can help reduce unwanted sound and increase comfort. However, before embarking on a soundproofing project, it’s essential to understand the cost involved.

Several factors influence the cost of soundproofing a wall. Understanding these factors can help you make informed decisions and allocate your budget effectively. Below, we will explore the key factors that influence soundproofing costs and provide a breakdown of common soundproofing options.

Factors Influencing Soundproofing Costs

1. Wall Material: The material of your existing wall plays a role in determining the overall soundproofing cost. Different materials have varying degrees of soundproofing capabilities, and some materials may require additional treatments to achieve the desired noise reduction.

2. Soundproofing Materials: The type of soundproofing materials used will impact the cost. There is a wide range of materials available, such as acoustic panels, soundproof insulation, mass loaded vinyl, and soundproofing foam. The cost will depend on the quality, thickness, and effectiveness of these materials.

3. Wall Size and Thickness: The size and thickness of the wall you want to soundproof will affect the cost. Larger walls require more materials, which can increase the overall expense. Additionally, thicker walls tend to provide better soundproofing but may require additional treatments, further impacting the cost.

4. Wall Condition and Accessibility: The condition of your existing wall and its accessibility can impact the cost of soundproofing. If your wall needs repairs or maintenance before soundproofing, it will add to the overall expense. Accessibility can also play a role, as harder-to-reach areas may require more labor and time.

5. Professional Installation vs. DIY: The method of installation will influence the cost. Hiring professionals to install soundproofing materials may come with additional labor charges, but it ensures proper installation and optimal soundproofing results. On the other hand, DIY installation can save costs but requires time, effort, and knowledge.

By considering these factors, you can estimate the cost of soundproofing your wall more accurately. It is essential to get multiple quotes from professionals and compare prices for different soundproofing options before making a decision.

In the next sections, we will provide a cost breakdown of common soundproofing options, giving you a better understanding of the expenses involved.

Introduction

Living in a noisy environment can be challenging and disruptive. Whether it’s the constant traffic sounds outside your window or the loud conversations from neighboring rooms, unwanted noise can affect your daily life and overall well-being. Thankfully, soundproofing techniques can help create a more peaceful and tranquil living or working space.

Soundproofing a wall involves adding specialized materials and techniques to minimize sound transmission, thereby reducing the impact of noise. This can be particularly beneficial for homeowners, renters, offices, recording studios, or anyone with a strong desire for privacy and a quieter environment.

However, before diving into a soundproofing project, it’s essential to understand the costs involved. The cost of soundproofing a wall can vary depending on several factors such as wall material, soundproofing materials used, wall size and thickness, wall condition and accessibility, and the method of installation.

In this article, we will explore these factors in detail and provide a comprehensive breakdown of common soundproofing options, giving you a better understanding of the expenses involved. By knowing the costs associated with each option, you can make an informed decision and choose the soundproofing solution that best fits your budget and requirements.

It’s important to note that while soundproofing a wall may require an initial investment, the long-term benefits are worth considering. A soundproofed space can improve sleep quality, enhance productivity, increase property value, and provide a sense of peace and serenity.

Whether you are soundproofing a bedroom, living room, home office, or any other space, this article will serve as a guide to help you navigate the various soundproofing options and their associated costs. So, let’s dive in and discover the ideal soundproofing solution that can transform your space into a haven of tranquility and relaxation.

Factors Influencing Soundproofing Costs

When it comes to soundproofing a wall, several key factors can impact the overall cost of the project. Understanding these factors will help you plan and budget accordingly. Here are the primary factors that influence soundproofing costs:

1. Wall Material: The material of your existing wall plays a significant role in determining the cost of soundproofing. Different wall materials have varying levels of sound transmission. For example, concrete walls are more soundproof than drywall. If your wall material doesn’t have good soundproofing properties, additional treatments may be required, adding to the overall cost.

2. Soundproofing Materials: The type of soundproofing materials used will also impact the cost. There is a wide range of materials available, each with varying degrees of effectiveness and price points. Some common soundproofing materials include acoustic panels, soundproof insulation, mass loaded vinyl (MLV), soundproofing foam, and green glue. The cost will depend on the quality, thickness, and coverage area required.

3. Wall Size and Thickness: The size and thickness of the wall you want to soundproof will affect the overall cost. Larger walls will require more materials, resulting in a higher expense. Additionally, thicker walls tend to provide better soundproofing. However, increasing the thickness of the wall may require additional treatments and materials, which can add to the costs.

4. Wall Condition and Accessibility: The condition of your existing wall and its accessibility can impact the soundproofing costs. If your wall has cracks, leaks, or other structural issues, these may need to be addressed before installing soundproofing materials, thus increasing the overall expense. Additionally, if the wall is challenging to access or requires extensive preparation work, the labor costs may be higher.

5. Professional Installation vs. DIY: Another factor to consider is whether you opt for professional installation or a do-it-yourself approach. While hiring professionals may come with additional labor costs, it ensures proper installation and optimal soundproofing results. On the other hand, DIY installation can help save money but requires time, effort, and the necessary expertise.

It’s important to note that the cost of soundproofing may vary depending on your specific needs and preferences. Researching different soundproofing options, obtaining multiple quotes from professionals, and comparing prices can help you make an informed decision and find the most cost-effective solution that meets your requirements.

In the next sections, we will provide a detailed cost breakdown of common soundproofing options, giving you a clearer idea of the expenses involved. Understanding these costs will empower you to make the right choices and create a peaceful and quiet environment within your space.

Wall Material

The material of your existing wall is a crucial factor when considering soundproofing options. Different wall materials have varying levels of sound transmission, which can affect the effectiveness of soundproofing solutions and the associated costs.

Here are some common wall materials and their soundproofing properties:

- Drywall: Drywall is a common wall material in residential and commercial buildings. While it provides some insulation against sound, it is not the most soundproof material. Additional soundproofing treatments may be needed to achieve optimal noise reduction.

- Concrete: Concrete walls are known for their excellent soundproofing capabilities. They inherently provide a good barrier to sound transmission. However, if your concrete walls are not sufficient for your specific noise concerns, additional soundproofing materials can be added to enhance their performance.

- Wood: Wood walls can vary in their soundproofing capabilities, depending on their thickness and construction. Generally, thicker wooden walls provide better sound insulation. However, some sound can still penetrate through wood, so supplementing with soundproofing materials might be necessary.

- Brick or stone: Brick or stone walls can offer moderate soundproofing qualities due to their density. However, sound can still pass through the mortar joints and any cracks or gaps. Adding soundproofing materials can improve their performance and reduce noise transmission.

The existing wall material will determine the level of soundproofing enhancement required and the associated cost. For example, if your wall is made of drywall and you desire significant noise reduction, you may need to consider using soundproofing materials such as acoustic panels, mass loaded vinyl (MLV), or soundproof insulation. On the other hand, if you have concrete walls, you may only need to add minor treatments for further noise reduction.

It’s important to consult with soundproofing professionals or experts who can evaluate your specific wall material and recommend the most suitable soundproofing solutions within your budget. They can help determine the combination of materials and techniques that will provide the desired results and offer the best value for your money.

By understanding the soundproofing capabilities of different wall materials, you can make informed decisions about the necessary soundproofing treatments and estimate the associated costs more accurately. This knowledge will guide you in selecting the most effective soundproofing options that align with your specific needs and budget limitations.

Soundproofing Materials

Soundproofing materials play a crucial role in reducing noise transmission and improving the overall soundproofing performance of a wall. Several options are available, each with their own characteristics, effectiveness, and cost considerations.

Here are some common soundproofing materials used in soundproofing walls:

- Acoustic Panels: Acoustic panels are specifically designed to absorb and reduce sound reflections. These panels can be made from various materials, such as foam, fabric-wrapped panels, or fiberglass. They are effective in improving sound quality and reducing unwanted noise. The cost of acoustic panels varies depending on the quality, size, and brand.

- Soundproof Insulation: Soundproof insulation is installed within the wall to enhance its soundproofing properties. It helps absorb and block sound vibrations. Common types of soundproof insulation include mineral wool, cellulose, and fiberglass insulation. The cost of soundproof insulation depends on the type, density, and quantity needed.

- Mass Loaded Vinyl (MLV): MLV is a heavy, vinyl-based material that adds mass to the wall, reducing sound transmission. It is commonly used as an effective sound barrier and can be applied directly to the wall or sandwiched between layers of other materials. The cost of MLV is determined by the thickness and quality of the vinyl.

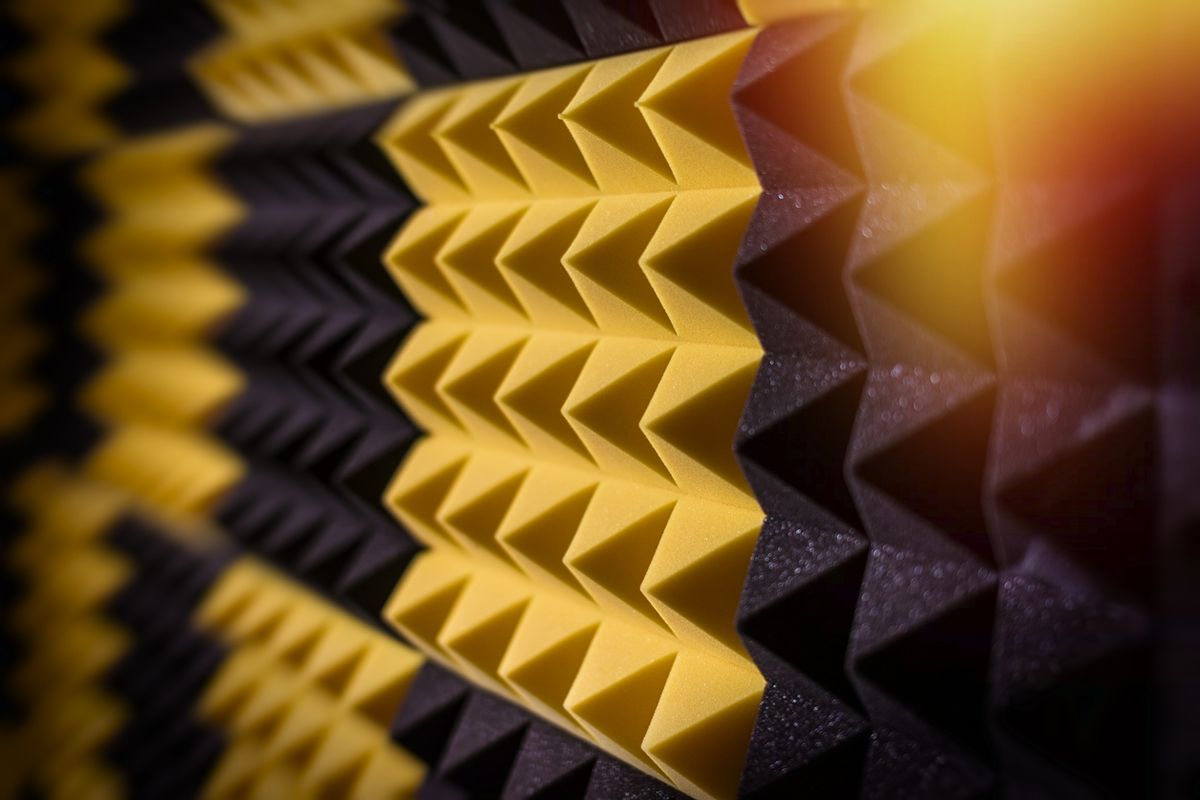

- Soundproofing Foam: Soundproofing foam is designed to absorb sound energy and reduce echoes. It comes in various shapes, such as pyramid or egg crate patterns, and is often used in recording studios or home theaters. The cost of soundproofing foam depends on the type, density, and quantity required.

- Green Glue: Green Glue is a viscoelastic compound that is sandwiched between two layers of drywall or another solid material. It converts sound energy into heat, reducing sound transmission. The cost of Green Glue is typically calculated per tube or pail and varies based on the quantity needed for the project.

The choice of soundproofing materials depends on the specific requirements of your project and your budget. It’s important to research and compare the features, effectiveness, and cost of different materials to find the best fit for your needs.

Working with soundproofing professionals or consultants can help you determine the most suitable materials for your project. They can evaluate your specific noise concerns, assess the existing wall construction, and recommend the appropriate combination of soundproofing materials that will provide the desired results.

Remember that the cost of soundproofing materials will vary based on factors such as quantity, quality, and brand. Obtaining multiple quotes from suppliers or contractors will help you compare prices and find the best value for your investment.

By understanding the different soundproofing materials available and their associated costs, you can make informed decisions when selecting the materials that will effectively reduce noise transmission and enhance the overall soundproofing performance of your walls.

Wall Size and Thickness

The size and thickness of the wall you want to soundproof are important factors that can influence the cost and effectiveness of your soundproofing project. Larger walls will require more materials, resulting in higher expenses.

Here are some considerations regarding wall size and thickness:

- Size: The size of the wall directly affects the amount of material needed for soundproofing. Larger walls will require more soundproofing materials, such as acoustic panels, mass loaded vinyl (MLV), or soundproof insulation. It’s essential to accurately measure the dimensions of your wall to estimate the quantity and cost of materials required.

- Thickness: The thickness of the wall also plays a role in soundproofing. Thicker walls tend to provide better sound insulation than thinner walls. However, keep in mind that increasing the thickness of the wall may require additional treatments or structural modifications, which can add to the overall cost.

For existing walls, adding soundproofing materials to the interior surface can help improve sound insulation. This can include options like acoustic panels, soundproof insulation, or mass loaded vinyl. The thickness of these materials will add to the overall thickness of the wall, providing enhanced soundproofing benefits.

In the case of new construction or major renovations, you may have the opportunity to consider thicker wall options from the beginning. Double-layer drywall or staggered stud wall construction are examples of techniques that can increase the overall thickness of the wall and improve soundproofing.

It’s important to consider the specific noise concerns and desired soundproofing goals when determining the size and thickness of your wall. Consulting with soundproofing professionals can help you evaluate your options and provide expert advice on the most suitable approaches for your project.

While larger and thicker walls may require a higher investment for soundproofing, they can provide more effective noise reduction and long-term benefits. Properly understanding the size and thickness of your wall will assist you in estimating the materials needed and ensuring that your soundproofing efforts are both effective and cost-efficient.

Wall Condition and Accessibility

The condition of your existing wall and its accessibility can significantly impact the cost of soundproofing. It’s important to consider the condition of the wall and any necessary repairs or modifications that may be required.

Here are some factors related to wall condition and accessibility that can influence soundproofing costs:

- Wall Repairs: If your wall has cracks, holes, or other structural issues, it’s essential to address them before soundproofing. Repairing the wall may involve patching, sealing, or reinforcing weak areas. The cost of these repairs will add to the overall expense of the soundproofing project.

- Wall Surface Preparation: Before installing soundproofing materials, the wall surface may need to be prepared. This can include cleaning, sanding, or applying a primer to ensure proper adhesion of the soundproofing materials. The time and effort required for surface preparation should be considered in the overall project cost.

- Accessibility: The accessibility of the wall can impact the cost of soundproofing. If the wall is easily accessible, it will be simpler to install soundproofing materials, resulting in lower labor costs. However, if the wall is difficult to reach or obstructed by furniture or fixtures, additional time and effort will be required for installation, potentially increasing the overall expenses.

It’s crucial to assess the condition of your wall and address any necessary repairs or modifications before embarking on a soundproofing project. This will ensure that the soundproofing materials can be installed effectively and provide the desired noise reduction results.

In some cases, it may be necessary to consult with a professional contractor or soundproofing expert who can evaluate the wall condition and recommend the appropriate treatments. They can also provide guidance on wall repairs and any additional modifications that may be required to optimize soundproofing performance.

By considering the condition of your wall and its accessibility, you can effectively plan and budget for any necessary repairs or modifications. This will help create a solid foundation for soundproofing and ensure that your investment in soundproofing materials yields the best possible results.

Professional Installation vs. DIY

When considering soundproofing a wall, one crucial decision to make is whether to hire professionals for installation or take the do-it-yourself (DIY) approach. Both options have their advantages and factors to consider.

Professional Installation: Hiring professionals to handle the installation of your soundproofing materials ensures that the job is done correctly and efficiently. Professionals have the knowledge, expertise, and specialized tools to effectively install the materials, resulting in optimal soundproofing performance. They can also provide advice on the best products and techniques for your specific needs. However, it’s important to note that professional installation typically comes with additional labor costs, which should be factored into your overall budget.

DIY Installation: Opting for a DIY approach can help save money on labor costs. It allows you to take control of the installation process and work at your own pace. However, DIY installation requires time, effort, and a certain level of skill. You need to research and learn about soundproofing techniques and ensure accurate installation for the best results. DIY installation may be suitable for smaller soundproofing projects or individuals who are comfortable with construction tasks.

When deciding between professional installation and DIY, consider the following factors:

- Complexity of the Project: Assess the complexity of your soundproofing project. If it involves intricate techniques or extensive modifications, professional installation may be the better choice to ensure accurate installation and optimal performance.

- Time and Availability: Evaluate your own availability and timeline. DIY installation may take longer due to the learning curve and the need to balance other commitments. If time is a constraint, professional installation can save you effort and ensure a quicker completion of the project.

- Safety and Liability: Consider the safety implications of the installation process. Some soundproofing techniques and materials may require specialized handling or pose potential risks. Professionals are trained to work safely, reducing the risk of accidents or damages. Additionally, professional installation may come with warranty coverage, providing peace of mind and liability protection.

- Budget: Carefully assess your budget and compare quotes from professionals with the cost of the materials alone for DIY installation. Consider the level of expertise required for your project and weigh the monetary value of professional installation against the potential risks and time commitment associated with DIY installation.

Whether you choose professional installation or DIY, it is essential to properly research soundproofing techniques, materials, and installation methods. Consultation with soundproofing professionals can also provide guidance and help you make an informed decision based on your specific needs, budget, and available resources.

Remember, the expertise and convenience of professional installation may come at an additional cost, but it can provide peace of mind and ensure that your soundproofing project is executed flawlessly, delivering long-lasting results.

Cost Breakdown of Common Soundproofing Options

Soundproofing a wall involves various techniques and materials, each with its own cost considerations. Understanding the cost breakdown of common soundproofing options can help you determine the most suitable solutions for your budget. Here are some popular soundproofing options and their associated costs:

- Acoustic Panels: Acoustic panels are an effective soundproofing solution, especially for managing echoes and improving sound quality. The cost of acoustic panels can vary based on the size, material, and brand. On average, acoustic panels can range from $50 to $200 per panel.

- Soundproof Insulation: Soundproof insulation, such as mineral wool or fiberglass, helps absorb and reduce sound transmission. The cost of soundproof insulation depends on the type, thickness, and quantity needed. On average, expect to spend around $0.50 to $3 per square foot for soundproof insulation.

- Mass Loaded Vinyl (MLV): MLV is a dense, vinyl-based material that adds mass to the wall, reducing sound transmission. MLV typically costs around $1 to $4 per square foot, with thicker and higher-quality options at the higher end of the price range.

- Soundproofing Foam: Soundproofing foam panels, commonly used in recording studios or home theaters, help absorb sound reflections. The cost of soundproofing foam depends on the type, density, and quantity required. Expect to spend around $1 to $5 per square foot for soundproofing foam.

- Green Glue: Green Glue is a popular soundproofing compound used between layers of drywall or other surfaces. It converts sound energy into heat, reducing sound transmission. Green Glue is typically sold in tubes or pails, with an average cost of $0.50 to $1 per square foot.

- Double Layer Drywall: Installing a second layer of drywall with a damping compound, such as Green Glue, can enhance soundproofing. The cost of double layer drywall depends on the size of the wall and the cost of the drywall sheets. On average, expect to spend $1 to $3 per square foot for double layer drywall.

- Soundproofing Curtains: Soundproofing curtains are designed to block out external noise and reduce sound reflections. The cost of soundproofing curtains varies based on the size, material, and brand. On average, soundproofing curtains can range from $50 to $200 per panel or set.

- Soundproofing Paint: Soundproofing paint contains special additives that help reduce sound transmission. The cost of soundproofing paint depends on the brand and coverage area. On average, expect to spend $40 to $100 for a gallon of soundproofing paint.

- Soundproofing Foam: Soundproofing foam panels, commonly used in recording studios or home theaters, help absorb sound reflections. The cost of soundproofing foam depends on the type, density, and quantity required. Expect to spend around $10 to $50 for a pack of soundproofing foam panels.

- Floating Wall Construction: Floating wall construction involves creating an air gap between the existing wall and a new wall to enhance soundproofing. The cost of floating wall construction depends on various factors, such as materials used, labor costs, and wall size. It is recommended to obtain quotes from contractors to estimate the cost accurately.

Keep in mind that the above cost ranges are approximate and can vary based on factors like labor costs, location, and quality. It’s advisable to obtain multiple quotes from suppliers or contractors to compare prices and find the best value for your soundproofing project.

By understanding the cost breakdown of common soundproofing options, you can allocate your budget effectively and choose the soundproofing solutions that align with your needs and financial resources. Remember to consider factors like the size of the wall, desired soundproofing level, and any additional labor or material costs associated with installation.

Acoustic Panels

Acoustic panels are a popular and effective soundproofing option, widely used in various settings such as recording studios, home theaters, offices, and even residential spaces. These panels are designed to absorb sound waves and reduce echoes, resulting in improved sound quality and reduced noise transmission.

The cost of acoustic panels can vary based on factors such as size, material, and brand. On average, acoustic panels can range from $50 to $200 per panel. The cost also depends on the type of material used in the panel construction.

There are different types of acoustic panels available, including foam panels, fabric-wrapped panels, and fiberglass panels. Foam panels, made from materials like polyurethane or melamine, are affordable and easy to install. They come in various sizes and thicknesses, providing flexibility in terms of design and customization. Fabric-wrapped panels, on the other hand, offer a more aesthetically pleasing appearance with a fabric cover. These panels can be customized to match the décor of the room while providing sound absorption. Fiberglass panels are highly effective at absorbing sound and are commonly used in professional recording studios.

The number of panels needed for your soundproofing project will depend on the size of the wall and the level of sound absorption required. It’s recommended to consult with soundproofing professionals or experts who can assess your space, determine the appropriate number and size of panels needed, and provide a more accurate cost estimate.

Installation of acoustic panels is typically straightforward and can be done using adhesive or mounting hardware. Some panels come with adhesive backing, while others require professional installation. If you have DIY skills, you may choose to install them yourself to save on labor costs. However, for larger and more complex projects, it is advisable to hire professionals to ensure proper installation and optimal soundproofing performance.

Acoustic panels not only contribute to soundproofing but also add a decorative element to any space. They are available in various shapes, sizes, and colors, allowing for creative and customizable designs. Additionally, acoustic panels can be moved or repositioned as needed, making them a versatile soundproofing solution.

By incorporating acoustic panels into your soundproofing project, you can achieve a significant reduction in reverberation, echoes, and overall noise transmission. They are a cost-effective and versatile option that enhances both the aesthetics and acoustic qualities of your space.

Soundproof Wallpaper

Soundproof wallpaper is an innovative and convenient solution for soundproofing walls. It combines the functionality of traditional wallpaper with sound-absorbing properties, allowing you to reduce noise transmission while adding style to your space. This option is particularly suitable for residential and commercial areas where traditional wallpaper is often used.

The cost of soundproof wallpaper varies depending on factors such as brand, design, and quality. On average, soundproof wallpaper can range from $50 to $150 per roll. The price per roll is influenced by the coverage area and the soundproofing capabilities of the wallpaper.

Soundproof wallpaper is crafted using materials that contain sound-absorbing properties such as foam, fabric, or specially designed acoustic materials. When installed properly, it can effectively dampen sound vibrations and reduce noise transfer between rooms, creating a more peaceful and comfortable environment. It is important to note that while soundproof wallpaper can provide some level of noise reduction, it may not be as effective as other soundproofing options like acoustic panels or soundproof insulation.

Installation of soundproof wallpaper is typically similar to the process of installing traditional wallpaper. It requires proper surface preparation, adhesive application, and careful alignment of the wallpaper rolls. Follow the manufacturer’s instructions or consult with a professional if you are unsure about the installation process. DIY installation can help save on labor costs, but if you are not confident in your wallpapering skills, it is advisable to hire a professional to ensure a smooth and secure installation.

One advantage of soundproof wallpaper is its ability to enhance the aesthetics of your space while providing soundproofing benefits. Soundproof wallpapers are available in a wide range of designs, patterns, and colors, allowing you to find a style that suits your taste and complements your existing décor. This versatility makes soundproof wallpaper an attractive option that seamlessly integrates with your interior design.

It’s important to note that soundproof wallpaper is most effective when combined with other soundproofing techniques and materials. For example, pairing it with acoustic panels or soundproof insulation can provide a more comprehensive soundproofing solution. Consulting with soundproofing experts can help you determine the best combination of materials and techniques for your specific needs.

Overall, soundproof wallpaper offers a practical and visually appealing option for soundproofing walls. It can improve the sound quality within your space and reduce noise transmission between rooms, creating a more comfortable and peaceful environment.

Soundproof Insulation

Soundproof insulation is a highly effective and commonly used method for soundproofing walls. It involves installing specialized insulation materials within the wall cavity to minimize noise transmission and improve soundproofing performance. Soundproof insulation not only reduces airborne sound but also helps dampen vibrations and impact noise, providing a more peaceful and quieter living or working environment.

The cost of soundproof insulation depends on various factors such as the type of insulation material, thickness, and coverage area. On average, soundproof insulation can range from $0.50 to $3 per square foot.

There are several types of soundproof insulation materials available, including mineral wool, cellulose, and fiberglass insulation. These materials have excellent sound-absorbing properties, which help absorb and dissipate sound waves. Mineral wool insulation, in particular, is known for its superior soundproofing capabilities and is commonly used in soundproofing projects. Fiberglass insulation, on the other hand, is more affordable and widely used in residential applications.

During the installation process, soundproof insulation is typically inserted into the wall cavities, effectively filling the space between the walls. It is crucial to ensure proper installation to maximize soundproofing performance. If you choose to handle the installation yourself, it’s important to follow the manufacturer’s instructions and guidelines carefully. However, to ensure proper installation and optimal results, hiring a professional installer is recommended.

Soundproof insulation not only improves soundproofing but also offers thermal insulation benefits. It helps regulate temperature, which can be advantageous in maintaining a comfortable and energy-efficient living or working space. This dual functionality of soundproof insulation adds value to your investment.

When considering soundproof insulation, it’s essential to evaluate the specific noise concerns you want to address. Factors such as the thickness of the insulation, the number of layers, and the overall soundproofing goals will influence the choice of insulation materials and the associated costs. Consulting with soundproofing professionals can provide valuable insights into selecting the most appropriate insulation material and determining the required quantity for your specific project.

Soundproof insulation is a long-term soundproofing solution that offers effective noise reduction and improved acoustic comfort. By properly insulating your walls, you can create a quieter and more relaxed environment, free from unwanted noise intrusion.

Mass Loaded Vinyl

Mass Loaded Vinyl (MLV) is a dense, flexible material widely used in soundproofing applications. It is designed to block sound transmission and reduce noise leakage through walls, floors, and ceilings. MLV is manufactured by incorporating heavy materials such as barium sulfate or calcium silicate into a vinyl matrix, resulting in a flexible yet dense barrier.

The cost of MLV typically ranges from $1 to $4 per square foot. The exact price depends on the thickness and quality of the MLV, as well as the brand chosen.

Installation of MLV is relatively straightforward. It can be hung directly on walls or ceilings using adhesive or nails. MLV can also be sandwiched between layers of drywall as an additional soundproofing measure. It is important to ensure proper sealing and overlap of the MLV sheets to prevent any gaps or air leaks that may compromise its soundproofing effectiveness.

The mass of MLV allows it to block sound waves, effectively reducing noise transmission. It adds density and mass to the wall, preventing sound vibrations from passing through. MLV is particularly advantageous for airborne sound reduction, such as speech or music. It is commonly used in homes, music studios, theaters, and commercial spaces.

One of the benefits of MLV is its flexibility and ease of installation. It can be cut into desired shapes and sizes, making it suitable for various soundproofing projects. Additionally, MLV is thin and lightweight compared to other soundproofing materials, which makes it easier to handle and install.

MLV can be used as a standalone soundproofing measure or in conjunction with other materials for enhanced performance. For example, combining MLV with additional layers of drywall or insulation can further improve soundproofing effectiveness.

It’s important to note that MLV alone may not provide sufficient noise reduction for very loud or low-frequency sounds, such as heavy machinery or bass vibrations. In such cases, consulting with soundproofing professionals is recommended to explore alternative or supplementary soundproofing solutions.

Overall, Mass Loaded Vinyl offers an effective and widely used soundproofing option. Its dense and flexible nature allows it to act as a barrier against sound transmission, creating a quieter and more comfortable environment. Incorporating MLV into your soundproofing project can significantly reduce noise intrusion and enhance acoustic privacy.

Green Glue

Green Glue is a unique soundproofing compound widely used to enhance the soundproofing capabilities of walls, ceilings, and other surfaces. It is known for its ability to convert sound vibrations into negligible heat energy, reducing noise transmission effectively.

The cost of Green Glue typically ranges from $0.50 to $1 per square foot. The exact price depends on factors such as the quantity needed and any additional applicator or dispenser equipment required.

Green Glue is easy to apply and can be used in new construction or renovation projects. It is typically applied between layers of drywall, plywood, or other solid surfaces. The compound is sandwiched between the existing surface and an additional layer of the chosen material, effectively creating a sound-damping sandwich. The Green Glue compound dissipates sound energy, preventing it from passing through the wall or ceiling.

The installation process with Green Glue is relatively straightforward. The compound is dispensed from specially designed tubes or pails and spread evenly onto one layer of the surface. The second layer is then applied on top of the compound, creating a strong bond. It is important to follow the manufacturer’s instructions and guidelines to ensure proper application for optimal soundproofing results.

The effectiveness of Green Glue can be enhanced by combining it with other soundproofing materials. For instance, using Green Glue in combination with double-layered drywall or mass-loaded vinyl (MLV) can yield even better soundproofing performance.

Green Glue offers several advantages as a soundproofing option. It contributes to improved sound isolation, creating a quieter and more comfortable living or working space. Additionally, Green Glue is non-toxic and environmentally friendly, making it a safe choice for both residential and commercial applications.

It is important to note that while Green Glue is effective for reducing airborne noise and sound vibrations, it may not be as effective for low-frequency noise or impact noise. In such cases, combining Green Glue with additional soundproofing techniques and materials can provide a more comprehensive soundproofing solution.

Consulting with soundproofing professionals can help you determine the most suitable use of Green Glue in your project, consider the specific noise concerns you want to address, and ensure that the compound is applied correctly.

Incorporating Green Glue into your soundproofing project can significantly enhance its effectiveness. The compound acts as a sound barrier, effectively reducing noise transmission and creating a more peaceful and acoustically pleasant environment.

Double Layer Drywall

Double layer drywall is a commonly used soundproofing technique that involves adding an extra layer of drywall to existing walls. This method is known for its effectiveness in reducing noise transmission through walls and enhancing soundproofing performance.

The cost of double layer drywall depends on the size of the wall and the cost of the drywall sheets. On average, the cost can range from $1 to $3 per square foot, including the cost of materials and installation.

The installation process for double layer drywall is similar to that of standard drywall installation. The additional layer of drywall is applied directly on top of the existing wall surface, creating a thicker and more substantial barrier. The joints between the layers are staggered or sealed with joint compound to minimize sound leakage.

The increased mass and thickness of double layer drywall contribute to improved sound insulation by reducing noise transmission between rooms or from external sources. The added layer of drywall helps absorb sound vibrations, reducing noise intrusion and creating a quieter indoor environment.

One important aspect of double layer drywall is the use of damping compounds, such as Green Glue, between the layers. The damping compound is applied to one side of the new drywall before installation, creating a viscoelastic layer that converts sound energy into heat, further enhancing soundproofing performance.

Double layer drywall is an effective soundproofing option for reducing both airborne noise and impact noise. It is commonly used in homes, apartments, offices, and other spaces where noise reduction is desired.

It’s important to note that double layer drywall does add thickness to the walls, which may slightly reduce floor area and affect other elements such as door frames. Proper planning and consideration of these factors are necessary before implementing this soundproofing technique.

While double layer drywall can significantly improve soundproofing, it may not be a standalone solution for extremely loud or low-frequency noise. Consider consulting with soundproofing professionals to assess your specific soundproofing needs and to explore additional soundproofing measures, such as combining double layer drywall with soundproof insulation or acoustic panels.

By utilizing double layer drywall, you can effectively enhance the soundproofing of your walls, reduce noise transmission, and create a more peaceful and comfortable indoor environment.

Soundproofing Curtains

Soundproofing curtains are a popular and convenient soundproofing solution, especially for windows and doors. These curtains are designed to absorb and block out external noise, making them an effective option for reducing sound transmission and creating a quieter space.

The cost of soundproofing curtains can vary depending on factors such as the size, material, and brand. On average, soundproofing curtains can range from $50 to $200 per panel or set.

Soundproofing curtains are typically made with multiple layers of heavy and dense materials, such as polyester fiber or foam. These dense materials help to absorb sound waves and prevent them from entering or leaving the room. The curtains are often designed with additional features such as sewn-in magnets or grommets to ensure a tight seal and further enhance soundproofing performance.

Installation of soundproofing curtains is relatively straightforward. They can be hung like regular curtains using rods or rails. It’s important to ensure that the curtains cover the entire opening and are properly sealed against the wall or window frame, minimizing any potential sound leakage.

One advantage of soundproofing curtains is their versatility. They can be easily installed and removed, making them a portable and flexible soundproofing solution. This flexibility allows you to use them in various spaces, such as bedrooms, living rooms, home offices, or even recording studios.

Soundproofing curtains not only provide effective noise reduction, but they can also enhance the aesthetic appeal of a room. They are available in a wide range of styles, colors, and patterns, allowing you to choose a design that complements your existing decor. Some soundproofing curtains also offer additional features like thermal insulation or light-blocking properties.

While soundproofing curtains can significantly reduce external noise, it’s important to note that they are most effective for high-frequency sounds and airborne noise. They may not provide as much reduction for low-frequency sounds or impact noise. In situations where a high level of soundproofing is required, it is recommended to combine soundproofing curtains with other soundproofing techniques and materials for optimal results.

It’s advisable to consult with soundproofing professionals or experts who can guide you in selecting the most appropriate soundproofing curtains for your specific needs and provide additional recommendations to enhance soundproofing performance in your space.

Incorporating soundproofing curtains into your soundproofing project can provide an effective and visually appealing solution for reducing noise intrusion and creating a quieter and more comfortable environment.

Soundproofing Paint

Soundproofing paint is a specialized type of paint designed to reduce sound transmission through walls, ceilings, and other surfaces. When applied correctly, it can help dampen sound vibrations and minimize noise intrusion into your living or working space.

The cost of soundproofing paint depends on factors such as brand, quality, and coverage area. On average, a gallon of soundproofing paint can range from $40 to $100. It is important to note that soundproofing paint is typically more expensive than regular paint due to the added sound-dampening properties.

Soundproofing paint contains special additives and compounds that work to absorb sound waves. The paint creates a viscoelastic surface that dissipates sound energy, reducing sound transmission between rooms and minimizing reverberation. However, it’s important to note that the effectiveness of soundproofing paint is limited compared to other soundproofing techniques and should be used in conjunction with other soundproofing materials for maximum results.

Application of soundproofing paint is similar to applying regular paint. It can be rolled or brushed onto walls, ceilings, or other solid surfaces. Multiple coats may be required to achieve the desired sound-dampening effect. It’s important to follow the manufacturer’s instructions and guidelines for proper application to ensure optimal performance.

Soundproofing paint not only enhances soundproofing but also offers other benefits. Some soundproofing paints offer thermal insulation properties, helping to regulate temperature and improve energy efficiency. Additionally, soundproofing paints can be tinted to match your desired color scheme, allowing you to maintain aesthetic continuity in your space.

While soundproofing paint provides a convenient and cost-effective option for reducing sound transmission, it is important to manage expectations. It is not a complete solution for all soundproofing needs, particularly for low-frequency or impact noise. Combining soundproofing paint with other soundproofing techniques, such as acoustic panels or soundproof insulation, can help achieve more comprehensive noise reduction in your space.

Consulting with soundproofing professionals or experts is recommended to assess your specific soundproofing requirements and to determine the most suitable combination of materials and techniques for your desired outcome.

Incorporating soundproofing paint into your soundproofing project can contribute to a quieter environment by reducing sound transmission and improving acoustics. While it may not provide a complete soundproofing solution on its own, it can be a valuable addition to your overall soundproofing strategy.

Soundproofing Foam

Soundproofing foam, also known as acoustic foam or sound-absorbing foam, is a popular and effective solution for reducing sound reflections and minimizing reverberation within a space. It is designed to absorb sound waves, thereby improving the acoustics and reducing noise levels within a room.

The cost of soundproofing foam depends on factors such as the type, thickness, and quantity required. On average, soundproofing foam can range from $10 to $50 for a pack of foam panels.

Soundproofing foam is typically made from open-cell polyurethane or melamine foam. It is available in various shapes, such as pyramids, wedges, or egg crates, which are designed to scatter and absorb sound waves effectively. The foam’s porous structure helps dissipate sound energy, preventing it from reflecting back into the room.

Installation of soundproofing foam is relatively easy. The foam panels can be attached to walls or ceilings using adhesive or double-sided tape. It is important to ensure proper placement and coverage for optimal sound absorption. The foam panels can also be arranged in different patterns to achieve the desired acoustic effect.

While soundproofing foam is highly effective at absorbing high-frequency sounds and reducing echoes, it may not provide as much reduction for low-frequency noises or impact noise. It is recommended to combine soundproofing foam with other materials, such as mass-loaded vinyl or soundproof insulation, to achieve comprehensive soundproofing.

Soundproofing foam offers additional benefits beyond noise reduction. It can enhance the clarity of audio playback within a room, making it a popular choice for home theaters, recording studios, or media rooms. Additionally, soundproofing foam can be a visually appealing addition to a space, as it is available in various colors and designs to complement the existing decor.

It’s important to note that soundproofing foam is distinct from sound-blocking foam, which is used to create a physical barrier to sound transmission. Soundproofing foam primarily focuses on improving the acoustics and sound absorption within a space.

When choosing soundproofing foam, consider factors such as the size of the room, the specific noise concerns you want to address, and the desired aesthetic appeal. Consulting with soundproofing professionals can help you determine the most suitable foam type, quantity, and placement for optimum soundproofing performance.

By incorporating soundproofing foam into your soundproofing project, you can effectively minimize sound reflections, improve acoustics, and create a more pleasant and controlled sound environment.

Floating Wall Construction

Floating wall construction is a soundproofing technique that involves creating an air gap between the existing wall and a new wall. This method helps isolate the new wall from the existing structure, minimizing the transfer of sound vibrations and reducing noise transmission. Floating walls are commonly used to soundproof shared walls, such as those between apartments or rooms.

The cost of floating wall construction can vary depending on factors such as the size of the wall and the cost of materials and labor. It is recommended to obtain quotes from contractors to estimate the cost accurately.

To create a floating wall, resilient channels or sound isolation clips are attached to the existing wall. These channels or clips act as a cushion, isolating the new wall from the structure and preventing sound vibrations from traveling through. The new wall, typically made of drywall or other soundproofing materials, is then attached to the resilient channels or clips, providing an additional soundproofing barrier.

The effectiveness of floating wall construction relies on the quality of the resilient channels or sound isolation clips used. These components are designed to absorb and dissipate sound vibrations, reducing their transmission through the wall system.

One key advantage of floating wall construction is that it can provide excellent soundproofing results, particularly for low-frequency noise and impact sounds. By creating a decoupled wall system, floating walls minimize the transfer of vibrations and reduce noise intrusion between adjacent spaces.

Floating wall construction requires skilled labor and expertise to ensure proper installation and maximize soundproofing performance. Hiring experienced professionals or soundproofing contractors is recommended to ensure precise construction and effective results.

It’s important to note that floating wall construction may involve additional considerations, such as electrical wiring, insulation, and fire safety compliance. Consulting with soundproofing professionals or contractors will help address these factors and ensure that the floating wall meets the necessary building codes and regulations.

While floating wall construction is a more involved soundproofing technique, it provides a comprehensive solution that can significantly reduce noise transmission and create a more peaceful living or working environment. By decoupling the new wall from the existing structure, floating wall construction helps to eliminate sound vibrations and create an effective soundproofing barrier.

Conclusion

Soundproofing a wall is a worthwhile investment for creating a peaceful and quiet environment. By understanding the factors that influence soundproofing costs, such as wall material, soundproofing materials, wall size and thickness, wall condition and accessibility, and the choice between professional installation and DIY, you can make informed decisions and allocate your budget effectively.

There are various soundproofing options available, each with its own cost considerations. Acoustic panels, soundproof wallpaper, soundproof insulation, mass loaded vinyl, soundproofing foam, double layer drywall, soundproofing curtains, soundproofing paint, and floating wall construction are among the common soundproofing solutions.

Each soundproofing option has its benefits and limitations, and the choice depends on your specific needs, budget, and desired results. Combining different soundproofing techniques and materials often yields the best outcomes.

It’s essential to consult with soundproofing professionals or experts who can assess your space, provide guidance, and recommend the most suitable soundproofing solutions for your specific requirements. They can ensure proper installation and optimal soundproofing performance.

Remember that while soundproofing can significantly reduce noise transmission, it may not eliminate all noise completely. It is important to set realistic expectations and understand the limitations of each soundproofing method.

In conclusion, soundproofing a wall can greatly enhance your living or working space, providing increased comfort, privacy, and tranquility. By considering the factors discussed in this article and exploring the various soundproofing options, you can create the ideal soundproofing solution that suits your needs and budget, ultimately creating a more peaceful and enjoyable environment.