Home>Production & Technology>Soundproofing>What Kind Of Foam Is Best For Soundproofing?

Soundproofing

What Kind Of Foam Is Best For Soundproofing?

Modified: February 18, 2024

Looking to soundproof your space? Discover the best foam options for effective soundproofing. Find out which type of foam will provide optimal noise reduction.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for AudioLover.com, at no extra cost. Learn more)

Table of Contents

Introduction

When it comes to creating a quiet and peaceful environment, soundproofing is essential. Whether you want to reduce noise from outside sources or create a soundproof room within your home or office, choosing the right materials is crucial. One such material that plays a significant role in soundproofing is foam.

Soundproofing foam is designed to absorb and dampen sound waves, minimizing the transmission of noise from one area to another. It serves as a barrier to external noise and helps create a quieter space, whether it’s for a recording studio, home theater, or office environment.

However, with so many different types of soundproofing foam available on the market, it can be overwhelming to determine which one is the best fit for your specific needs. In this article, we will explore the different types of foam commonly used in soundproofing and provide insights on how to choose the best foam for your setup.

To make an informed decision, it’s crucial to understand the various factors that come into play when selecting soundproofing foam. These factors include the desired level of sound attenuation, the frequency range you want to target, the installation process, and the overall aesthetics of the space.

As we delve into the different types of soundproofing foam, you’ll discover that each material possesses unique properties and features. Some foams specialize in absorbing high-frequency sounds, while others excel at blocking low-frequency noises. The right choice depends on your specific soundproofing goals and the nature of the noise you are trying to minimize or eliminate.

In the upcoming sections, we will explore popular types of soundproofing foam, including acoustic foam, polyurethane foam, melamine foam, and fiberglass insulation. Each type has its own strengths and considerations, allowing you to make an educated decision when it comes to soundproofing your space.

Understanding Soundproofing Foam

Soundproofing foam is a specialized material designed to reduce the transmission of sound waves. It is typically made from foam or foam-like materials with specific properties that absorb, dissipate, or block sound energy.

Soundproofing foam works by absorbing sound waves as they pass through the material, converting them into heat energy. The foam’s cellular structure, density, and thickness contribute to its sound-absorbing capabilities.

When sound waves encounter the cells of the foam, the air within the cells vibrates and transforms the sound energy into heat. This process reduces the intensity of the sound, making the surrounding environment quieter.

It’s important to note that soundproofing foam is not designed to block sound completely. Instead, it helps to reduce and control the noise level within a space. This is particularly beneficial in environments where echo, reverberation, or external noise sources need to be minimized.

One key concept to understand when working with soundproofing foam is sound absorption coefficient. This coefficient represents the amount of sound energy absorbed by the foam material. It is measured on a scale of 0 to 1, with higher values indicating greater sound absorption.

Another important factor to consider is the frequency range the foam is effective at absorbing. Different foams have varying effectiveness at absorbing different frequencies. Low-frequency sounds, such as heavy bass, may require thicker and denser foam to achieve effective soundproofing.

It’s also worth mentioning that soundproofing foam comes in different shapes and sizes, including foam panels, corner bass traps, ceiling tiles, and more. These different forms allow for versatile application and can be tailored to specific soundproofing needs.

Overall, understanding the underlying principles of soundproofing foam is crucial to selecting the right type and achieving the desired level of noise reduction. It is essential to consider factors such as the sound absorption coefficient, foam density, thickness, and the specific requirements of the space you wish to soundproof.

Factors to Consider When Choosing Soundproofing Foam

When selecting soundproofing foam, there are several important factors to consider to ensure that you choose the right foam for your specific needs. These factors will help determine the effectiveness and suitability of the foam for your soundproofing goals. Here are some key considerations:

1. Soundproofing Requirements: Consider the level of soundproofing you require for your space. Are you looking to minimize external noise, reduce echo and reverberation, or create a completely soundproof environment? Different types of foam have varying sound absorption properties, so understanding your specific soundproofing goals will guide you in selecting the appropriate foam.

2. Frequency Range: Pay attention to the frequency range of the sound you want to control. Some foams are better at absorbing high-frequency sounds, such as voices or high-pitched noises, while others excel at blocking low-frequency sounds, such as heavy bass. Determine the dominant frequency range in your environment to choose foam that effectively targets those frequencies.

3. Foam Density: Foam density is an important factor in soundproofing. Higher density foam tends to be more effective at blocking sound due to its increased mass. However, denser foam may also be heavier and more challenging to install. Consider the balance between density and practicality when selecting foam.

4. Thickness: Foam thickness affects its sound-absorbing capabilities. Thicker foam provides more surface area for sound waves to interact with, increasing the level of absorption. Consider the available space and your specific soundproofing needs when determining the optimal thickness for your foam.

5. Fire Safety: Depending on the purpose and location of your soundproofing project, fire safety may be a consideration. Look for foam materials that meet fire safety standards to ensure the protection of your space.

6. Installation and Aesthetics: Consider the ease of installation and the visual impact of the foam. Some foams are self-adhesive, making installation quick and easy. Others may require additional adhesive or mounting hardware. Additionally, consider the aesthetic appeal of the foam in your space, as some foams come in various colors or can be covered with fabric for a more visually appealing finish.

7. Budget: Lastly, consider your budget. Soundproofing foam comes in various price ranges, depending on the material, quality, and brand. Determine your budget and explore options within that range to find the best foam that meets your needs and financial considerations.

By carefully considering these factors, you can select the soundproofing foam that will provide optimal noise reduction and control for your specific environment and requirements. Remember to prioritize your soundproofing goals while balancing practicality, aesthetics, and budget.

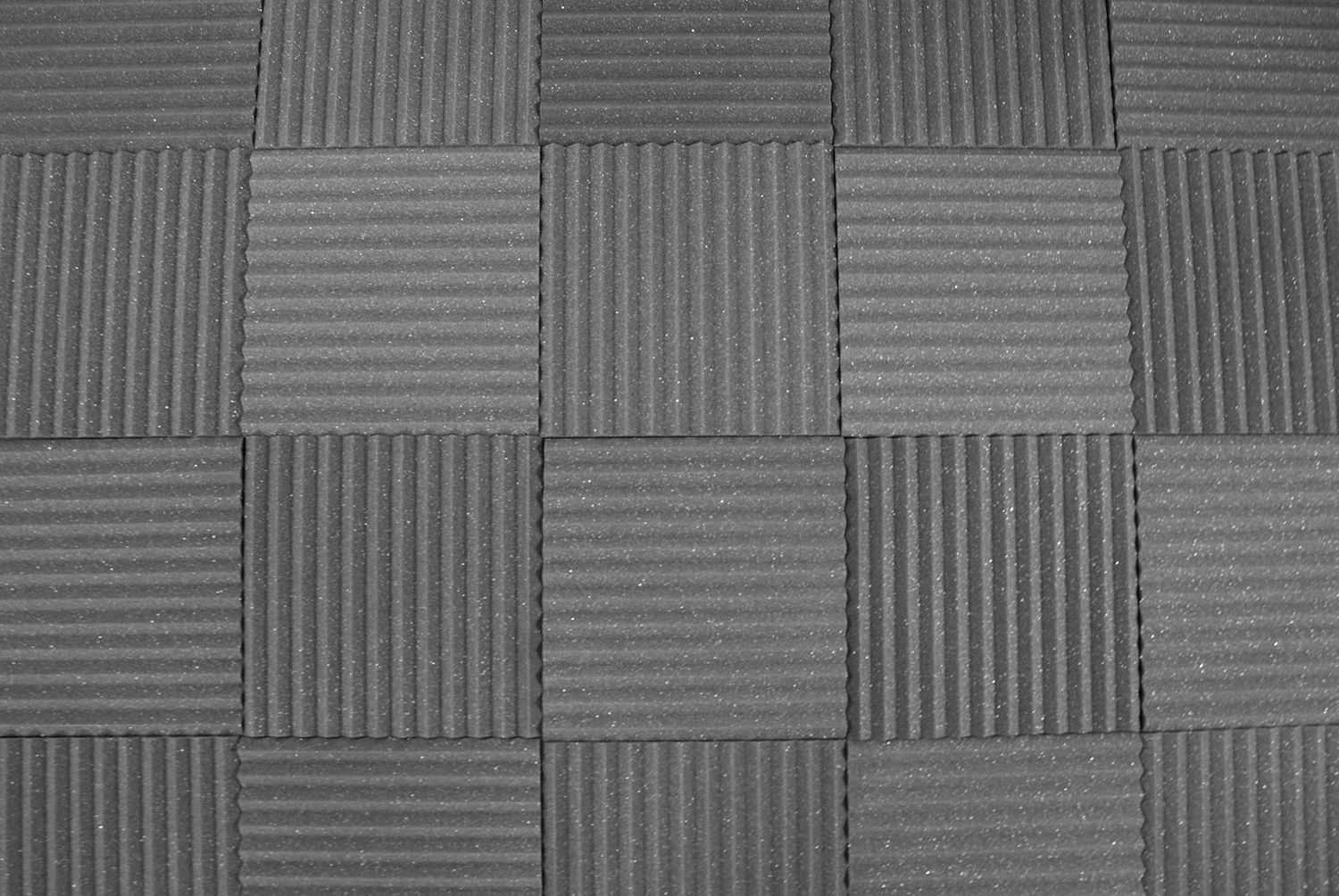

Different Types of Soundproofing Foam

Soundproofing foam comes in various types, each with its own unique properties and applications. Understanding the different types of foam will help you choose the most suitable option for your soundproofing needs. Here are some commonly used types of soundproofing foam:

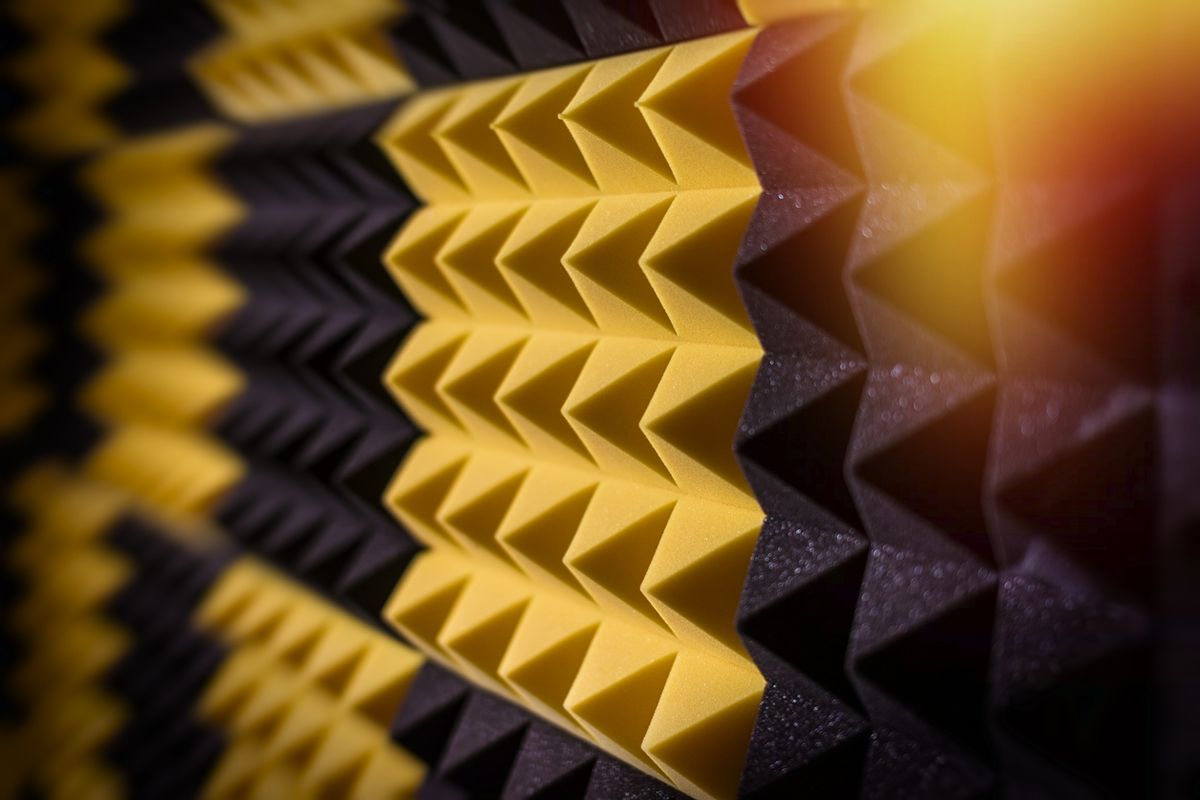

1. Acoustic Foam: Acoustic foam, also known as studio foam or sound-absorbing foam, is a popular choice for soundproofing applications. It is made from open-cell polyurethane foam and is designed to absorb and reduce high-frequency sound waves. Acoustic foam has a distinct pyramidal or wedge-shaped design, which helps to scatter and diffuse sound waves, minimizing echoes and reverberations. It is often used in recording studios, home theaters, and practice rooms.

2. Polyurethane Foam: Polyurethane foam is a versatile and widely used material for soundproofing. It is available in various densities and thicknesses, offering different levels of sound absorption and insulation. Polyurethane foam is known for its excellent noise reduction properties and is effective at absorbing both high and low-frequency sounds. It is commonly used in applications such as wall and ceiling panels, industrial enclosures, and HVAC systems.

3. Melamine Foam: Melamine foam, also known as acoustic foam panels or foam wedges, is another popular option for soundproofing. It is made from a foam-like material derived from melamine resin. Melamine foam has unique properties that make it highly effective at absorbing sound, especially in the mid to high-frequency range. It is often used in commercial spaces, offices, and soundproofing treatments for walls and ceilings.

4. Fiberglass Insulation: While not strictly foam, fiberglass insulation is worth mentioning as it is commonly used for soundproofing. It is made from thin glass fibers and is well-known for its excellent thermal insulation properties. However, fiberglass insulation also offers sound absorption capabilities, making it an effective choice for reducing noise transmission. It is commonly used in walls, ceilings, and floors to control both airborne and impact noises.

Each type of soundproofing foam has its strengths and considerations, so it’s important to carefully evaluate your specific soundproofing goals and the nature of the noise you wish to address. Consider factors such as the frequency range, density, thickness, ease of installation, and budget when selecting the most suitable foam for your project. By choosing the right type of soundproofing foam, you can significantly improve the acoustics of your space and create a more peaceful and enjoyable environment.

Acoustic Foam

Acoustic foam is a widely used type of soundproofing foam that specializes in absorbing high-frequency sound waves. It is commonly known as studio foam or sound-absorbing foam. Acoustic foam is made from open-cell polyurethane foam, which gives it its distinct characteristics and performance.

The unique design of acoustic foam, typically in a pyramid or wedge shape, serves a specific purpose. The shape helps scatter and diffuse sound waves, reducing echoes and reverberations in a room. This design allows the foam to absorb sound energy and prevent it from bouncing back into the space, resulting in clearer and sharper audio quality.

Acoustic foam is commonly used in recording studios, music venues, home theaters, and any space that requires precise sound control. It improves sound clarity by absorbing unwanted reflections and reducing background noise. The foam’s open-cell structure and porous surface increase the surface area available for sound absorption, enhancing its efficiency.

When installing acoustic foam, it is crucial to consider the layout and arrangement. Placing the foam strategically on the walls, ceilings, or other surfaces can effectively target the areas where sound reflection is most problematic. By covering larger expanses of the room with acoustic foam, you can achieve better overall sound control and isolation.

It’s important to note that while acoustic foam is excellent at absorbing high-frequency sounds, it may be less effective at blocking lower-frequency noises. For comprehensive soundproofing, combining acoustic foam with other materials, such as fiberglass insulation or heavy mass barriers, may be necessary.

Acoustic foam comes in various options, including different densities, thicknesses, and shapes. The density of the foam affects its sound absorption capabilities, with higher density foam offering better performance. Thicker foam is generally more effective at absorbing sound due to its increased surface area.

Acoustic foam is typically lightweight, making it easy to install using adhesive or specialized mounting hardware. It can be cut into different shapes or sizes to fit specific areas or customized installations.

Overall, acoustic foam is an excellent choice for controlling sound reflections, reducing echo, and enhancing sound quality in a variety of environments. Its versatility and effectiveness make it a favored option for soundproofing projects that require precise audio control and improved acoustics.

Polyurethane Foam

Polyurethane foam is a versatile and widely used material for soundproofing applications. It offers excellent noise reduction properties and is effective at absorbing both high and low-frequency sounds. Polyurethane foam is made from a flexible and durable material that allows it to be molded into different shapes and sizes.

One of the key advantages of polyurethane foam is its ability to absorb and dissipate sound energy. Its open-cell structure enables sound waves to penetrate the foam, where they are converted into heat energy through friction and vibrations within the cells. This process reduces the intensity of the sound, resulting in a quieter environment.

The density of polyurethane foam plays a critical role in its soundproofing capabilities. Higher density foam tends to be more effective at blocking sound due to its increased mass and ability to absorb and dampen sound waves. Thicker foam can also provide added noise reduction benefits due to its larger surface area for sound absorption.

Polyurethane foam is commonly used in various soundproofing applications, such as wall and ceiling panels, industrial enclosures, and HVAC systems. It can be applied to walls to reduce noise transmission through them, or installed in air ducts and pipes to minimize sound leakage. Additionally, polyurethane foam can be used to create sound barriers within a room or to insulate against airborne and impact noises.

Another advantage of polyurethane foam is its ease of installation. It is available in various forms, including foam sheets, rolls, and panels, which can be cut to size and easily adhered to surfaces using adhesive. Some polyurethane foam products come with a self-adhesive backing, making installation even more convenient.

Furthermore, polyurethane foam is known for its durability and resistance to moisture, making it suitable for both indoor and outdoor soundproofing applications. It is resilient and able to maintain its soundproofing properties over time without deteriorating. Additionally, it is often flame retardant, enhancing safety in a variety of environments.

However, it’s important to note that polyurethane foam alone may not provide complete sound isolation. To achieve comprehensive soundproofing, it may be necessary to combine polyurethane foam with other soundproofing materials, such as mass-loaded vinyl or additional insulation.

Overall, polyurethane foam is a versatile and effective option for soundproofing. Its ability to absorb a wide range of frequencies, ease of installation, and durability make it a popular choice for various applications where noise reduction is desired.

Melamine Foam

Melamine foam, also known as acoustic foam panels or foam wedges, is a popular choice for soundproofing due to its exceptional sound absorption properties. Melamine foam is derived from melamine resin, giving it unique characteristics that make it highly effective at reducing noise.

One of the key advantages of melamine foam is its ability to absorb sound in the mid to high-frequency range. It excels at absorbing frequencies where human speech and most environmental noises occur, making it an excellent choice for reducing noise in commercial spaces, offices, and other areas where clear communication is important.

The unique structure of melamine foam enhances its sound absorption capabilities. The foam consists of open-cell foam structures with numerous interconnected strands and irregularly shaped cells. This intricate design provides a large surface area for sound waves to interact with, increasing its sound-absorbing efficiency.

When sound waves enter the foam, they travel through the open-cell structure, causing the foam to vibrate. This vibration converts the sound energy into heat energy through friction, effectively dissipating the sound and reducing its intensity. The result is a significant reduction in echoes, reverberation, and background noise.

Aside from its soundproofing capabilities, melamine foam also offers other advantages. It is lightweight and easy to handle, making installation a simple and hassle-free process. Melamine foam is often available in various sizes and shapes, such as foam panels or wedges, allowing for versatility in soundproofing applications.

Furthermore, melamine foam has excellent fire-resistant properties, making it a safe choice for soundproofing projects. It is engineered to resist combustion and has a high tolerance to heat, ensuring the protection and safety of the space being soundproofed.

It’s important to note that while melamine foam is highly effective at absorbing sound in the mid to high-frequency range, it may not provide as much attenuation for low-frequency sounds. To achieve comprehensive soundproofing, combining melamine foam with other materials, such as fiberglass insulation or mass-loaded vinyl, may be necessary.

In summary, melamine foam is a versatile and effective option for soundproofing applications. Its ability to absorb mid to high-frequency sounds, lightweight nature, easy installation, and fire-resistant properties make it an ideal choice for commercial spaces, offices, and other environments where noise reduction and improved acoustics are desired.

Fiberglass Insulation

Fiberglass insulation is a commonly used material for soundproofing, primarily known for its excellent thermal insulation properties. However, it also offers effective sound absorption capabilities, making it an advantageous option for reducing noise transmission in various applications.

Fiberglass insulation is made from thin glass fibers that are bound together to create a dense and flexible material. It is available in the form of batts, rolls, or loose-fill, allowing for easy installation in walls, ceilings, and floors. While its main purpose is to provide insulation against temperature transfer, it also helps to control both airborne and impact noises.

One of the key advantages of fiberglass insulation in soundproofing is its ability to absorb and dampen sound waves. When sound waves encounter the fibers of the insulation, they are forced to travel through the material’s many nooks and crannies. This process disrupts and weakens the sound waves, reducing their intensity and minimizing noise transmission.

Fiberglass insulation is particularly effective at absorbing high-frequency sounds, such as voices and ambient noise. Its thick and dense structure allows it to trap and dissipate these sounds, helping to create a quieter and more peaceful environment.

Another advantage of fiberglass insulation is its versatility. It can be used in various settings, including residential, commercial, and industrial spaces. Fiberglass insulation is often installed between walls, in ceilings, and under floors to improve the soundproofing capabilities of these areas. It can also be used around pipes and ductwork to minimize sound leakage.

While fiberglass insulation offers excellent sound absorption properties, it’s important to note that it may not provide complete sound isolation. For optimal soundproofing, combining fiberglass insulation with other soundproofing materials, such as mass-loaded vinyl or gypsum boards, may be necessary to achieve the desired level of noise reduction.

It’s worth mentioning that working with fiberglass insulation requires caution due to its potential to release tiny glass fibers into the air if mishandled. It is recommended to wear protective clothing, gloves, and a mask when installing fiberglass insulation to minimize the risk of skin irritation or respiratory issues.

In summary, fiberglass insulation is a versatile and effective material for soundproofing applications. Its ability to absorb high-frequency sounds, ease of installation, and thermal insulation properties make it a popular choice in residential, commercial, and industrial settings. When used in conjunction with other soundproofing materials, fiberglass insulation can significantly improve the acoustic performance of a space while reducing noise transmission.

Conclusion

Soundproofing foam plays a vital role in creating a quiet and peaceful environment by minimizing the transmission of sound waves. Understanding the different types of foam and their unique properties is essential to selecting the best option for your specific soundproofing needs.

Acoustic foam is ideal for absorbing high-frequency sounds and reducing echoes, making it a popular choice for recording studios, home theaters, and other spaces where precise audio control is important. Polyurethane foam offers excellent sound absorption capabilities across a broad frequency range and is commonly used in wall and ceiling panels, HVAC systems, and industrial enclosures.

Melamine foam excels at absorbing mid to high-frequency sounds, making it suitable for commercial spaces, offices, and areas where clear communication is essential. And fiberglass insulation, primarily known for thermal insulation, also provides effective sound absorption properties, making it a versatile option for reducing noise transmission in walls, ceilings, and floors.

When choosing soundproofing foam, consider factors such as soundproofing requirements, frequency range, foam density and thickness, installation process, fire safety, and budget. By carefully evaluating these factors, you can select the most suitable foam that meets your specific soundproofing goals and fits your project’s practical and financial considerations.

Remember that soundproofing foam is not meant to completely block sound but rather to reduce noise levels and control sound reflections. Depending on the level of soundproofing desired, combining foam with other materials may be necessary to achieve comprehensive noise reduction and isolation.

In conclusion, selecting the right soundproofing foam can greatly enhance the acoustic performance of a space, creating a more peaceful and enjoyable environment. By understanding the different types of foam and considering key factors, you can make an informed decision and achieve optimal soundproofing results for your specific needs.