Home>Production & Technology>Soundproofing>How Does Soundproofing Foam Work

Soundproofing

How Does Soundproofing Foam Work

Modified: March 12, 2024

Discover how soundproofing foam works and effectively reduces noise. Learn how to soundproof your space with this essential soundproofing technique.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for AudioLover.com, at no extra cost. Learn more)

Table of Contents

Introduction

Have you ever found yourself trying to concentrate on a task, only to be interrupted by the constantly buzzing noise from outside your window or the echoes from the neighboring room? Unwanted noise can be a major source of distraction and can greatly affect our ability to focus and relax. That’s where soundproofing foam comes in.

Soundproofing foam is a popular and effective solution for reducing noise and creating a quieter environment. Whether you want to create a peaceful home office, a recording studio, or simply block out the noises from outside, soundproofing foam can be the answer.

But how does soundproofing foam actually work? In this article, we will delve into the science behind soundproofing foam and explore its different types, installation methods, and the factors to consider when choosing the right foam for your needs. So, let’s get started!

Soundproofing foam, also known as acoustic foam, is a specialized material designed to absorb sound waves and reduce the transmission of sound. It is typically made from open-cell polyurethane foam, which has excellent sound-absorbing properties.

What is Soundproofing Foam?

Soundproofing foam, also known as acoustic foam, is a type of material specifically engineered to reduce and absorb sound waves. It is commonly used in various industries, such as music studios, home theaters, offices, and even residential homes, where noise reduction is desired.

This foam is made from open-cell polyurethane foam, which is known for its excellent sound-absorbing properties. The unique structure of the foam allows it to trap sound waves and convert them into heat energy.

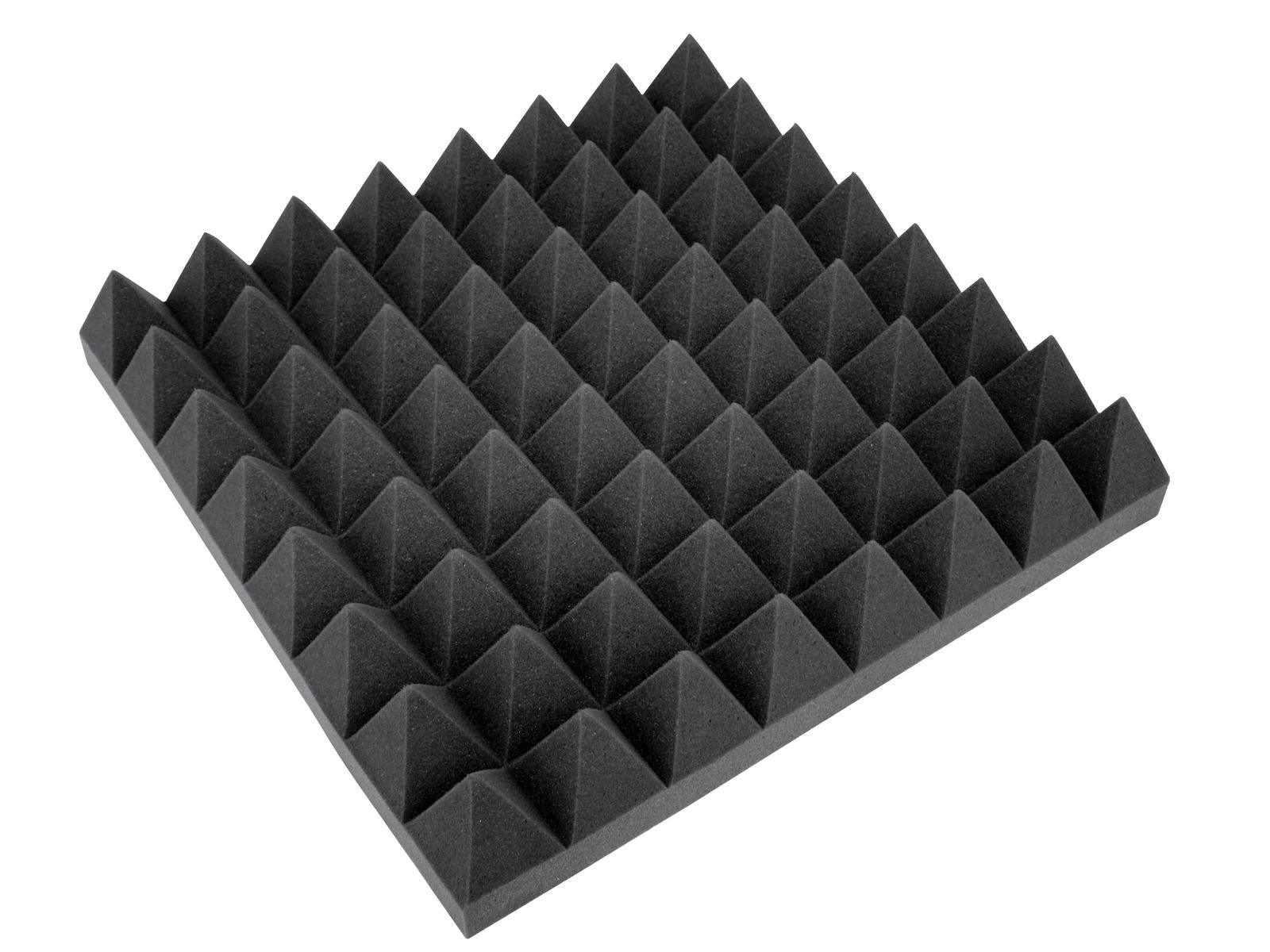

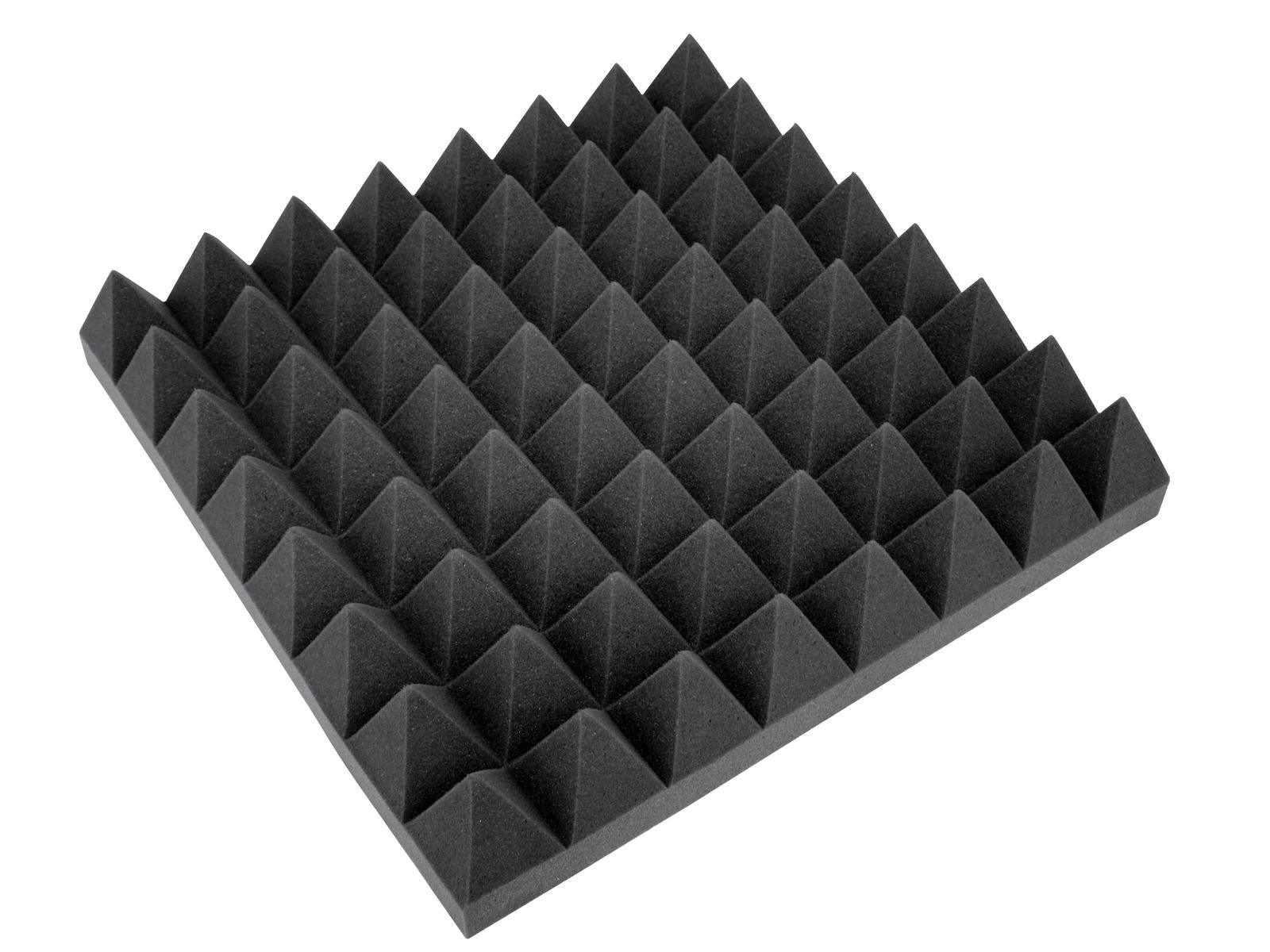

Soundproofing foam comes in various shapes and sizes, including panels, tiles, and bass traps. The most common form is the egg crate design, characterized by its convoluted surface, which enhances the foam’s sound-absorbing capabilities.

Unlike regular foam or insulation materials, soundproofing foam is specifically designed to target and attenuate certain frequencies of sound. It is able to absorb sound waves across a wide spectrum, from low-frequency sounds like rumbling bass to high-frequency sounds like squealing voices.

One important aspect to note is that soundproofing foam does not completely block or isolate sound. Instead, it reduces the intensity and echo of the sound, making the environment more acoustically balanced. It is particularly effective at reducing unwanted echoes, reverberations, and reflections that can create a noisy and disruptive environment.

Overall, soundproofing foam provides a practical and cost-effective solution for noise reduction. It is a versatile material that can be easily installed on walls, ceilings, and other surfaces to achieve optimal sound absorption.

How Does Soundproofing Foam Reduce Noise?

Soundproofing foam works by employing a combination of absorption and diffusion techniques to reduce the transmission of sound waves and minimize the impact of noise. Understanding the mechanisms at play can help us grasp the effectiveness of soundproofing foam in creating a quieter environment.

The main way soundproofing foam reduces noise is through sound absorption. When sound waves enter a room, they bounce off the surfaces, creating echoes and reverberations. Soundproofing foam is designed to absorb these sound waves, converting their energy into heat and preventing them from bouncing back into the room.

The open-cell structure of soundproofing foam allows for efficient sound absorption. When sound waves encounter the foam, they travel through the porous structure, and the numerous air pockets within the foam cause the sound waves to lose energy as they are absorbed. This helps to reduce the overall noise level within the space.

Another way soundproofing foam reduces noise is through diffusion. Diffusion is the scattering of sound waves in different directions, breaking up the direct path that sound waves would otherwise travel. The uneven surface of soundproofing foam, with its contours and convoluted design, helps to scatter sound waves and prevent them from traveling in a focused direction.

Furthermore, soundproofing foam has the ability to trap low-frequency sounds, such as heavy bass or rumbling noises. These frequencies tend to be more difficult to control and can easily penetrate through other materials. With its dense composition and acoustic properties, soundproofing foam effectively absorbs and dissipates low-frequency vibrations, reducing their impact on the surrounding environment.

It’s important to note that the effectiveness of soundproofing foam depends on factors such as thickness, density, and the specific type of foam used. Thicker and denser foams generally provide better noise absorption performance. Additionally, combining soundproofing foam with other soundproofing techniques and materials, such as mass-loaded vinyl or resilient channels, can further enhance its noise reduction capabilities.

In summary, soundproofing foam reduces noise by absorbing sound waves and converting them into heat energy, as well as scattering sound waves through diffusion. Its unique design and composition make it an effective tool in creating a quieter and more comfortable environment by minimizing echoes, reverberations, and the overall impact of noise.

Absorption Mechanism of Soundproofing Foam

The absorption mechanism is a key factor in understanding how soundproofing foam effectively reduces noise. Soundproofing foam utilizes its unique structure and material properties to absorb sound waves and convert their energy into heat.

The absorption process begins when sound waves reach the surface of the foam. The open-cell structure of soundproofing foam allows sound waves to penetrate deep into the material. As the sound waves travel through the foam, they encounter countless air pockets within the foam.

These air pockets act as resonators, effectively capturing and dissipating sound energy. As the sound waves enter the foam, they cause the air within the foam to vibrate. This vibration transforms the acoustic energy of the sound waves into heat energy, effectively reducing the intensity of the sound.

The porous nature of the foam also plays a crucial role in the absorption process. The open-cell structure creates a large surface area, allowing for more interactions between the sound waves and the foam material. This, in turn, enhances the sound absorption capabilities of the foam.

Additionally, the convoluted surface of soundproofing foam further improves its absorption performance. The irregular contours, such as the familiar egg crate design, create a larger surface area for sound waves to interact with, resulting in increased absorption efficiency.

It’s important to consider the thickness and density of the foam when assessing its absorption capabilities. Thicker foams can absorb lower frequencies more effectively, while denser foams provide better overall noise reduction. The specific type and formulation of the foam also contribute to its absorption properties.

Furthermore, soundproofing foam is designed to target specific frequency ranges. Different foam types have varying absorption coefficients across different frequencies. This allows for customization and optimization of the foam’s performance to address the specific noise concerns of different environments.

Overall, the absorption mechanism of soundproofing foam allows it to effectively reduce noise by capturing sound energy and converting it into heat. By utilizing an open-cell structure, porous material, and convoluted surface design, soundproofing foam provides an efficient solution for sound absorption in a wide range of applications.

Types of Soundproofing Foam

Soundproofing foam comes in various types and forms, each specifically designed to cater to different noise reduction needs and environments. Understanding the different types of soundproofing foam can help you choose the most suitable option for your specific requirements. Here are some commonly used types:

- Acoustic Panels: Acoustic panels are one of the most popular types of soundproofing foam. They are flat, rigid panels made of sound-absorbing materials, such as open-cell foam or fiberglass. These panels are typically mounted on walls or ceilings to reduce echo and reverberation within a room.

- Bass Traps: Bass traps are specialized soundproofing foam designed to absorb low-frequency sounds, particularly the prominent bass frequencies. They are typically placed in corners of a room, where low-frequency sound waves tend to accumulate. Bass traps help to minimize bass buildup and improve the overall sound quality of a room.

- Egg Crate Foam: Egg crate foam is characterized by its distinctive egg crate-like pattern on the surface. It is an economical and versatile option for soundproofing. Egg crate foam is commonly used in recording studios, home theaters, and other environments where sound absorption and diffusion are desired.

- Wedge Foam: Wedge foam features a wedge-shaped design with alternating peaks and valleys. This design enhances the sound diffusion and absorption capabilities of the foam. Wedge foam is commonly used in recording studios, control rooms, and concert halls to create an acoustically balanced environment.

- Convoluted Foam: Convoluted foam is similar to egg crate foam in terms of its design but offers a slightly different texture. It provides effective sound absorption and diffusion across a wide range of frequencies. Convoluted foam is often used in home theaters, vocal booths, and other applications where sound quality is critical.

It’s important to note that the performance of soundproofing foam can vary based on the specific materials used, the thickness and density of the foam, and the overall design of the product. Additionally, some soundproofing foam options come with a self-adhesive backing, making installation quick and easy.

Before choosing a specific type of soundproofing foam, consider the specific noise issues you’re trying to address, the frequencies you need to target, and the aesthetics of the space. Consulting with a soundproofing professional or doing thorough research can help you make an informed decision.

By selecting the appropriate type of soundproofing foam, you can effectively improve the acoustic quality and reduce unwanted noise in your living space, office, or studio.

Installation of Soundproofing Foam

Installing soundproofing foam is a relatively straightforward process that can be done by anyone with basic DIY skills. Proper installation is crucial to ensure optimal noise reduction and the longevity of the foam. Here are some general guidelines to follow when installing soundproofing foam:

- Prepare the Surface: Start by cleaning the surface where the foam will be installed. Remove any dirt, dust, or grease that may hinder the adhesive from sticking properly.

- Measure and Cut: Measure the dimensions of the wall or surface you wish to cover with soundproofing foam. Use a utility knife or scissors to cut the foam panels or sheets to the appropriate size and shape.

- Apply Adhesive: If your soundproofing foam has a self-adhesive backing, simply peel off the protective film and firmly press the foam onto the desired surface. Alternatively, you can use a specific adhesive formulated for soundproofing foam. Apply the adhesive according to the manufacturer’s instructions and press the foam onto the surface, ensuring good contact and adherence.

- Install in Sections: For larger areas, it’s often more manageable to install the foam in sections. Start at one corner or edge and work your way across, ensuring a tight and seamless fit between each piece of foam.

- Seal the Edges: To prevent sound from leaking around the edges of the foam, consider using a sealant or foam seal tape. Apply the sealant or tape along the edges of the foam to create a tight seal and enhance the soundproofing performance.

- Consider Room Acoustics: Take into account the specific characteristics of the room and the placement of soundproofing foam. Experiment with different arrangements and positions to achieve the best acoustic balance and noise reduction.

It’s worth noting that soundproofing foam can also be used in conjunction with other soundproofing techniques, such as installing mass-loaded vinyl or soundproof curtains, to further enhance noise reduction.

If you are unsure about the installation process or have complex soundproofing needs, it’s recommended to consult with a professional soundproofing expert. They can provide personalized advice and ensure the best results for your specific situation.

Remember to prioritize safety during installation and carefully follow all instructions provided by the manufacturer. With proper installation, soundproofing foam can effectively reduce unwanted noise and create a more peaceful and comfortable environment.

Factors to Consider When Choosing Soundproofing Foam

When selecting soundproofing foam for your specific needs, it’s important to consider several factors to ensure the best results and maximum noise reduction. Here are some key factors to keep in mind when choosing soundproofing foam:

- Noise Reduction Requirements: Determine the level of noise reduction you require. Consider the type of noise you want to address, whether it’s external noise like traffic or internal noise like echoes. Different types of foam have varying levels of sound absorption and diffusion capabilities.

- Frequency Range: Understand the frequency range of the unwanted noise you wish to mitigate. Different foams have different absorption coefficients across various frequencies. Choose a foam that effectively absorbs the specific frequency range you are targeting.

- Thickness and Density: Thicker and denser foam generally provides better soundproofing performance. Thicker foam can absorb lower frequencies more effectively, while denser foam offers overall noise reduction. Consider the thickness and density that will best suit your requirements.

- Installation Flexibility: Determine how you intend to install the soundproofing foam. Some foam options have self-adhesive backing, making installation quick and easy. Others may require adhesive or mounting hardware. Consider the installation process and your skill level for a hassle-free installation.

- Aesthetics: Think about the appearance of the foam and how it will blend with your existing decor. Some foam types come in various colors and finishes, allowing you to choose a style that matches your preferences and the overall aesthetic of the space.

- Budget: Consider your budget and determine how much you are willing to invest in soundproofing foam. Different foam types and brands come at various price points. Strike a balance between quality and affordability to ensure you get the best value for your money.

- Fire Safety: Verify the fire safety properties of the soundproofing foam. Foam that meets fire safety standards will provide an added layer of protection and peace of mind.

- Reviews and Recommendations: Read consumer reviews and seek recommendations from professionals or trusted sources. Real-life experiences and expert opinions can provide valuable insights and help you make an informed decision.

By considering these factors, you can choose the most suitable soundproofing foam for your specific needs, ensuring effective noise reduction and a more peaceful environment.

Benefits and Limitations of Soundproofing Foam

Soundproofing foam offers several benefits when it comes to reducing noise and improving the acoustic quality of a space. However, it’s essential to consider its limitations to have realistic expectations. Here are the benefits and limitations of soundproofing foam:

Benefits:

- Efficient Noise Reduction: Soundproofing foam is highly effective at absorbing and reducing unwanted noise. It can minimize echoes, reverberations, and the transmission of sound waves, creating a quieter and more pleasant environment.

- Wide Frequency Range Absorption: Depending on the type and quality, soundproofing foam can absorb sound waves across a wide frequency range, from low frequencies to high frequencies. This makes it suitable for reducing different types of noise, from bass-heavy sounds to high-pitched frequencies.

- Easy Installation: Installation of soundproofing foam is typically straightforward and can be done by anyone with basic DIY skills. Foam with self-adhesive backing makes the installation process even simpler.

- Versatile Applications: Soundproofing foam can be used in various environments, including recording studios, home theaters, offices, apartments, and more. It is suitable for both residential and commercial spaces.

- Customizable Options: Soundproofing foam comes in different types, thicknesses, and shapes, allowing for customization based on individual requirements and needs. This enables you to choose the foam that best suits your specific noise reduction goals.

Limitations:

- Sound Isolation: Soundproofing foam primarily reduces noise by absorbing and diffusing sound waves. However, it does not provide complete sound isolation. It may not be able to block out extremely loud noises or vibrations completely.

- Specific Frequency Range: Different foam types have varying absorption coefficients across different frequencies. It is important to choose the foam that matches the specific frequency range of the noise you wish to reduce.

- Installation Coverage: Depending on the size of the space and the specific soundproofing foam used, complete coverage of the entire surface may be necessary to achieve optimal results. This could require larger quantities of foam and contribute to the overall cost.

- Room Aesthetics: While soundproofing foam can improve the acoustic quality of a space, its appearance may not always align with the desired design aesthetic. Foam with limited color and finish options may not blend seamlessly with the existing decor.

- Fire Safety: Not all soundproofing foam options meet fire safety standards. It is important to consider the fire safety properties of the foam to ensure compliance with building codes and regulations.

Considering these benefits and limitations will help you make an informed decision when choosing soundproofing foam, allowing you to achieve effective noise reduction while understanding its practical constraints.

Conclusion

Soundproofing foam is a valuable tool for reducing noise and improving the acoustic quality of various spaces. Whether you want to create a peaceful home office, a professional recording studio, or simply block out external disturbances, soundproofing foam can be an effective solution.

Throughout this article, we have explored the mechanism behind soundproofing foam and how it absorbs and reduces sound waves. The different types of foam, including acoustic panels, bass traps, egg crate foam, wedge foam, and convoluted foam, offer flexibility and customization options to address specific noise reduction needs.

Installation of soundproofing foam is relatively simple, making it accessible for anyone with basic DIY skills. The foam’s ability to absorb and diffuse sound waves helps create a quieter environment by minimizing echoes, reverberations, and the transmission of noise.

When choosing soundproofing foam, it’s important to consider factors such as noise reduction requirements, frequency range, thickness, density, installation flexibility, aesthetics, budget, and fire safety. These considerations will ensure that you select the most suitable foam for your specific needs and achieve optimal noise reduction results.

While soundproofing foam offers numerous benefits, it’s crucial to understand its limitations as well. Soundproofing foam does not provide complete sound isolation and may require extensive coverage for optimal results. Additionally, its appearance and fire safety properties should be taken into account.

In conclusion, soundproofing foam is an effective solution for creating a quieter and more acoustically balanced environment. By utilizing the absorption and diffusion properties of foam, you can reduce unwanted noise and enhance the overall comfort of your space. Consider the specific requirements and limitations of soundproofing foam to make an informed decision and achieve maximum noise reduction benefits.