Home>Production & Technology>Soundproofing>What Foam Is Used In Soundproofing

Soundproofing

What Foam Is Used In Soundproofing

Published: January 26, 2024

Enhance the acoustic performance of your space with soundproofing foam. Learn about the different foam types used in effective soundproofing solutions.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for AudioLover.com, at no extra cost. Learn more)

Table of Contents

Introduction

Welcome to the world of soundproofing! Whether you’re looking to create a peaceful oasis in your home or minimize noise in a commercial space, understanding the different types of foam used in soundproofing is essential. From open-cell foam to mineral wool, each material has its unique properties and performance characteristics.

Soundproofing is the process of reducing or blocking unwanted noise. It involves using various techniques and materials to absorb, dampen, or reflect sound waves. One of the most effective methods is using specialized foams that are designed to absorb and control sound.

In this article, we will explore the different types of foam commonly used in soundproofing applications. We will delve into the features and benefits of each type, giving you a comprehensive understanding of the options available and helping you choose the right foam for your specific soundproofing needs.

So, whether you’re planning to soundproof a home theater, recording studio, office space, or bedroom, read on to discover the foam materials that can significantly enhance the acoustic performance of your space.

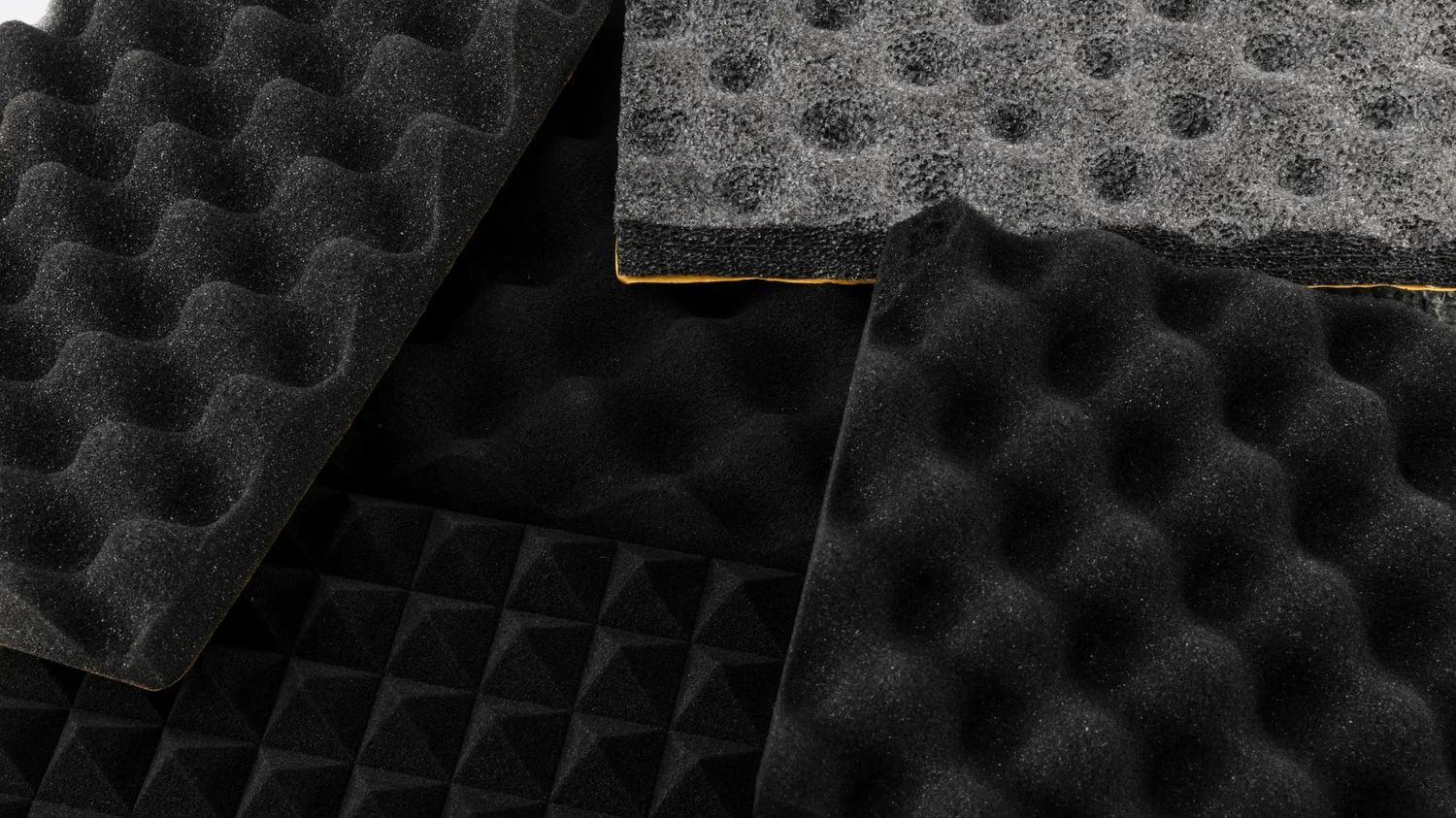

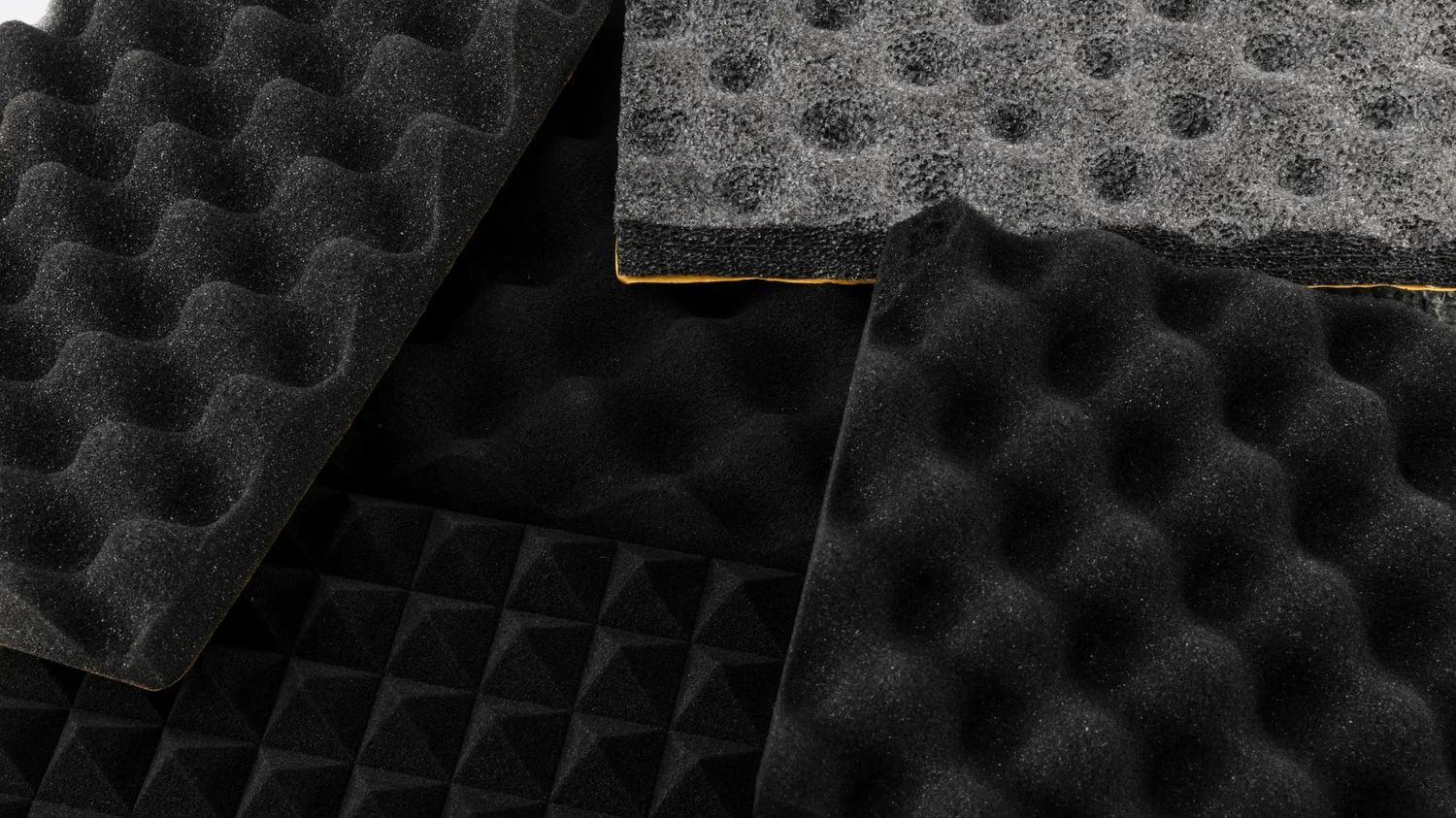

Acoustic Foam

Acoustic foam is a popular choice for soundproofing due to its excellent sound absorption properties. It is made from open-cell polyurethane foam and is designed to dissipate sound energy effectively. Acoustic foam is lightweight, easy to install, and highly effective at reducing echo, reverberation, and other unwanted noise.

One of the key features of acoustic foam is its unique structure, consisting of irregular patterns with peaks and valleys. This design helps to scatter and absorb sound waves, preventing them from bouncing off surfaces and creating echoes. The foam’s open-cell structure allows it to trap and absorb sound energy, converting it into heat.

When installing acoustic foam, it is essential to consider the thickness and density of the material. Thicker foam panels offer better sound absorption, especially for lower frequencies. Additionally, higher density foam is more effective at blocking sound transmission through walls or ceilings.

Acoustic foam is commonly used in recording studios, home theaters, broadcasting rooms, and other spaces where sound quality and clarity are essential. It can be easily cut into various shapes and sizes, allowing for customized installations. It is important to note that while acoustic foam is excellent at absorbing sound within a room, it may not provide significant soundproofing from external noise.

Overall, acoustic foam provides an effective solution for reducing echo and improving sound quality within a space. Its versatility, ease of installation, and affordability make it a popular choice for both professional and DIY soundproofing projects.

Open-Cell Foam

Open-cell foam is a type of foam with interconnected air pockets or cells. These cells allow air and sound to pass through, making open-cell foam an excellent material for soundproofing applications. It is known for its high sound absorption capabilities, making it effective in reducing noise levels and improving acoustics in various environments.

One of the key advantages of open-cell foam is its ability to absorb sound waves by converting them into heat energy. The open structure of the foam allows sound to penetrate and get trapped within the air pockets, reducing the transmission of sound through walls, floors, or ceilings. This makes it an ideal material for soundproofing walls, recording studios, and home theaters.

Open-cell foam is also lightweight and flexible, making it easy to install and shape according to the specific requirements of a room. It can be cut into different sizes and thicknesses to fit into wall cavities, furniture, or ceiling panels. This flexibility allows for creative and customized soundproofing solutions.

In addition to its soundproofing capabilities, open-cell foam also provides thermal insulation. The trapped air within the foam cells helps to prevent heat transfer, improving energy efficiency and reducing heating or cooling costs.

However, it is essential to note that while open-cell foam is effective at absorbing and reducing sound, it may not provide complete soundproofing for extremely loud or intense noises. In such cases, a combination of different soundproofing materials and techniques may be required for optimal results.

Overall, open-cell foam is a versatile and effective option for soundproofing applications. Its ability to absorb sound waves, flexibility in installation, and additional thermal insulation properties make it a popular choice for achieving both acoustic comfort and energy efficiency in various spaces.

Closed-Cell Foam

Closed-cell foam is another type of foam commonly used in soundproofing applications. Unlike open-cell foam, closed-cell foam is composed of cells that are completely closed, preventing the passage of air or sound waves. This unique structure gives closed-cell foam excellent soundproofing capabilities and makes it ideal for blocking and reducing noise.

One of the primary advantages of closed-cell foam is its high density and rigidity. This density allows the foam to effectively block sound and minimize sound transmission through walls, floors, or ceilings. Closed-cell foam acts as a barrier, preventing sound waves from passing through and reducing the overall noise levels in a space.

Additionally, closed-cell foam has excellent thermal insulation properties. The tightly packed cells create a barrier to heat transfer, helping to maintain a comfortable and energy-efficient environment. This makes closed-cell foam a popular choice for soundproofing applications in spaces where thermal insulation is also desired.

Another benefit of closed-cell foam is its resistance to moisture and water absorption. The closed-cell structure prevents water or other liquids from seeping into the foam, making it a suitable option for soundproofing in damp or high-humidity environments.

Closed-cell foam is available in various thicknesses and can be easily cut and shaped to fit specific soundproofing needs. It can be used on walls, ceilings, floors, or even as a wrapping material around pipes or HVAC ducts to reduce noise transmission.

It is important to note that while closed-cell foam is highly effective at blocking sound, it may not provide the same level of sound absorption as open-cell foam. Consequently, it is often used in combination with other sound-absorbing materials to achieve optimal soundproofing results.

In summary, closed-cell foam offers excellent soundproofing capabilities, thermal insulation, and resistance to moisture. Its density and rigidity make it an effective barrier against noise, making it a suitable choice for both residential and commercial soundproofing projects.

Polyurethane Foam

Polyurethane foam is a versatile and widely used material in various industries, including soundproofing. It is known for its excellent insulation properties, durability, and ease of installation. Polyurethane foam can be found in both open-cell and closed-cell forms, providing different soundproofing benefits depending on the specific application.

Open-cell polyurethane foam is soft and flexible, allowing sound waves to penetrate and get absorbed within the foam’s interconnected air pockets. This type of foam is effective at reducing high-frequency noise, echoes, and reverberation. It is commonly used in recording studios, home theaters, and other spaces where clear sound quality is essential.

Closed-cell polyurethane foam, on the other hand, has a denser structure with sealed cells, preventing the passage of air and sound waves. This type of foam is more rigid and provides better sound blocking capabilities. It is often used to create sound barriers in walls, ceilings, or floors, preventing noise transmission between different areas or from outside sources.

Polyurethane foam is known for its durability and long-term performance. It is resistant to moisture, mold, and mildew, making it suitable for soundproofing applications in damp or humid environments. Additionally, polyurethane foam has excellent thermal insulation properties, contributing to energy efficiency and reducing heating or cooling costs.

Installation of polyurethane foam is relatively straightforward. It can be cut into various shapes and sizes to fit specific areas, such as wall cavities or ceiling panels. Polyurethane foam can be adhered to surfaces using adhesive or installed with mechanical fasteners, depending on the soundproofing requirements.

It is important to note that while polyurethane foam is effective at absorbing or blocking sound, it may not provide complete soundproofing for extremely loud or intense noises. In such cases, a combination of different soundproofing techniques, such as adding additional layers or using specialized barriers, may be required.

In summary, polyurethane foam offers versatility, durability, and excellent soundproofing properties. Whether you need to improve sound quality, block external noise, or enhance energy efficiency, polyurethane foam can be a practical choice for your soundproofing needs.

Melamine Foam

Melamine foam, also known as acoustic foam or soundproofing foam, is a unique type of foam with exceptional sound-absorbing properties. It is made from a melamine resin, which gives the foam its distinctive open-cell structure. Melamine foam is widely used in soundproofing applications due to its high-performance acoustic properties and fire-resistant nature.

One of the key benefits of melamine foam is its ability to absorb a wide range of sound frequencies, including high-frequency noises. The open-cell structure of the foam allows sound waves to enter the foam and get trapped within the interconnected cells. This absorption process converts the sound energy into heat, reducing echoes, reverberation, and overall noise levels in a room.

Melamine foam is particularly effective at absorbing sound in environments where clear communication and sound quality are crucial, such as recording studios, conference rooms, or lecture halls. Its ability to eliminate disruptive echoes and background noise creates a more acoustically controlled and comfortable environment.

In addition to its sound-absorbing properties, melamine foam is fire-resistant, making it a safe option for soundproofing in commercial and public spaces. The foam is inherently flame-resistant and does not release toxic fumes when exposed to fire, providing an added layer of safety.

Furthermore, melamine foam has a high resistance to chemicals and can withstand various cleaning agents, making it suitable for soundproofing applications in areas that require regular cleaning or disinfection.

Installing melamine foam is relatively simple. The foam is lightweight and can be easily cut into different shapes and sizes to fit specific needs. It can be affixed to walls, ceilings, or other surfaces using adhesive or mechanical fasteners.

However, it is important to note that melamine foam alone may not provide significant sound blocking capabilities. In combination with other soundproofing materials, such as barriers or dense insulation, melamine foam can be employed to achieve optimal soundproofing results.

In summary, melamine foam offers excellent sound absorption properties and fire resistance, making it a valuable material for soundproofing applications. Whether you need to improve acoustics in a recording studio or create a quieter workspace, melamine foam can play a crucial role in enhancing sound quality and reducing noise levels.

Mineral Wool

Mineral wool, also known as rock wool or mineral fiber, is a popular choice for soundproofing due to its exceptional sound-absorbing and thermal insulation properties. It is made from natural or synthetic minerals, such as basalt or slag, which are spun into fibers and formed into batts, boards, or loose-fill material.

One of the key advantages of mineral wool is its high density and fibrous structure, which allows it to effectively absorb sound waves. The fibers trap and dissipate sound energy, reducing echoes, reverberation, and overall noise levels in a room. Mineral wool is particularly effective at absorbing low to mid-range frequencies, making it suitable for soundproofing applications in homes, offices, or commercial spaces.

In addition to its soundproofing capabilities, mineral wool is also an excellent thermal insulator. Its dense structure helps to reduce heat transfer through walls, ceilings, or floors, contributing to energy efficiency and reducing heating or cooling costs.

Mineral wool is available in various forms, including batts, boards, or loose-fill material. Batts and boards are commonly used to insulate walls, ceilings, and floors, providing both soundproofing and thermal insulation. Loose-fill mineral wool is often used to fill cavities or gaps in walls or ceilings where soundproofing properties are desired.

Furthermore, mineral wool has fire-resistant properties, making it a safe choice for soundproofing applications. The fibers are non-combustible and can withstand high temperatures without releasing toxic fumes. This makes mineral wool a preferred option in environments where fire safety is a concern.

Installation of mineral wool is relatively straightforward. Batts or boards can be cut to size and easily placed between studs or joists, while loose-fill material can be blown into cavities or enclosed spaces. It is important to ensure proper fitting and coverage to achieve optimal soundproofing and thermal insulation results.

Overall, mineral wool is a versatile and effective material for soundproofing. Its sound-absorbing, thermal insulation, and fire-resistant properties make it an ideal choice for improving acoustics and comfort in various residential and commercial spaces.

Fiberglass

Fiberglass is a widely used material in the construction industry, including soundproofing applications. It is made from small fibers of glass that are woven together to form insulation batts or boards. Fiberglass offers excellent sound absorption and thermal insulation properties, making it a popular choice for soundproofing projects.

One of the primary advantages of fiberglass is its ability to absorb sound waves. The small fibers within the insulation material are designed to trap and dissipate sound energy, reducing echoes and noise levels in a room. Fiberglass insulation is particularly effective at absorbing high-frequency sounds, making it suitable for soundproofing walls, ceilings, or floors.

In addition to its soundproofing properties, fiberglass is also an excellent thermal insulator. The trapped air pockets within the insulation material help to prevent heat transfer, improving energy efficiency and reducing heating or cooling costs.

Fiberglass insulation is available in different forms, including batts, rolls, and boards. Batts and rolls are commonly used to insulate walls, ceilings, and floors, providing both soundproofing and thermal insulation benefits. Fiberglass boards are often used in applications where rigidity and durability are required, such as soundproofing mechanical rooms or equipment enclosures.

Installation of fiberglass insulation is relatively straightforward. Batts or rolls can be cut to fit between studs or joists and are typically snugly placed against the cavities being insulated. Fiberglass boards can be secured to surfaces using nails or adhesive. It is important to ensure proper fitting and coverage to achieve optimal soundproofing and thermal insulation results.

When installing fiberglass insulation, it is crucial to wear protective clothing, including gloves, a mask, and safety glasses, as the tiny glass fibers can irritate the skin, eyes, and respiratory system. Following safety guidelines and precautions during installation is essential.

Overall, fiberglass insulation offers a cost-effective and versatile solution for soundproofing. Its sound absorption, thermal insulation, and affordability make it a popular choice for improving acoustics and comfort in both residential and commercial spaces.

Conclusion

Soundproofing is a valuable investment for creating peaceful and acoustically optimized spaces. Understanding the different types of foam and insulation materials used in soundproofing is essential to make informed decisions and achieve the desired results.

Acoustic foam provides excellent sound absorption properties, making it ideal for reducing echoes and reverberation within a room. Its open-cell structure allows sound waves to enter and get trapped, converting them into heat energy.

Open-cell foam offers flexibility and ease of installation, effectively absorbing sound and improving acoustics. Closed-cell foam, on the other hand, provides superior sound blocking properties, preventing sound transmission through walls, floors, or ceilings.

Polyurethane foam is a versatile choice for soundproofing, providing both sound absorption and thermal insulation. Its durability and easy installation make it a popular option for various applications.

Melamine foam offers exceptional sound absorption and fire-resistant properties, making it suitable for environments where clear sound transmission and safety are crucial.

Mineral wool is a high-density material that excels in both soundproofing and thermal insulation. Its fibrous structure effectively absorbs sound waves while reducing heat transfer.

Fiberglass insulation is a widely-used material known for its sound absorption and thermal insulation capabilities. It offers affordability and versatility for soundproofing projects.

In conclusion, selecting the right foam or insulation material for soundproofing depends on the specific needs of the space and the desired outcome. By understanding the unique characteristics of each material, you can make an informed decision to create a quieter, more comfortable environment with improved acoustics.