Home>Instruments>Harmonica>How Is A Harmonica Made

Harmonica

How Is A Harmonica Made

Published: February 3, 2024

Discover the fascinating process of how a harmonica is made, from the intricate reed placements to the skilled craftsmanship involved. Learn about the inner workings of this beloved musical instrument.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for AudioLover.com, at no extra cost. Learn more)

Table of Contents

Introduction

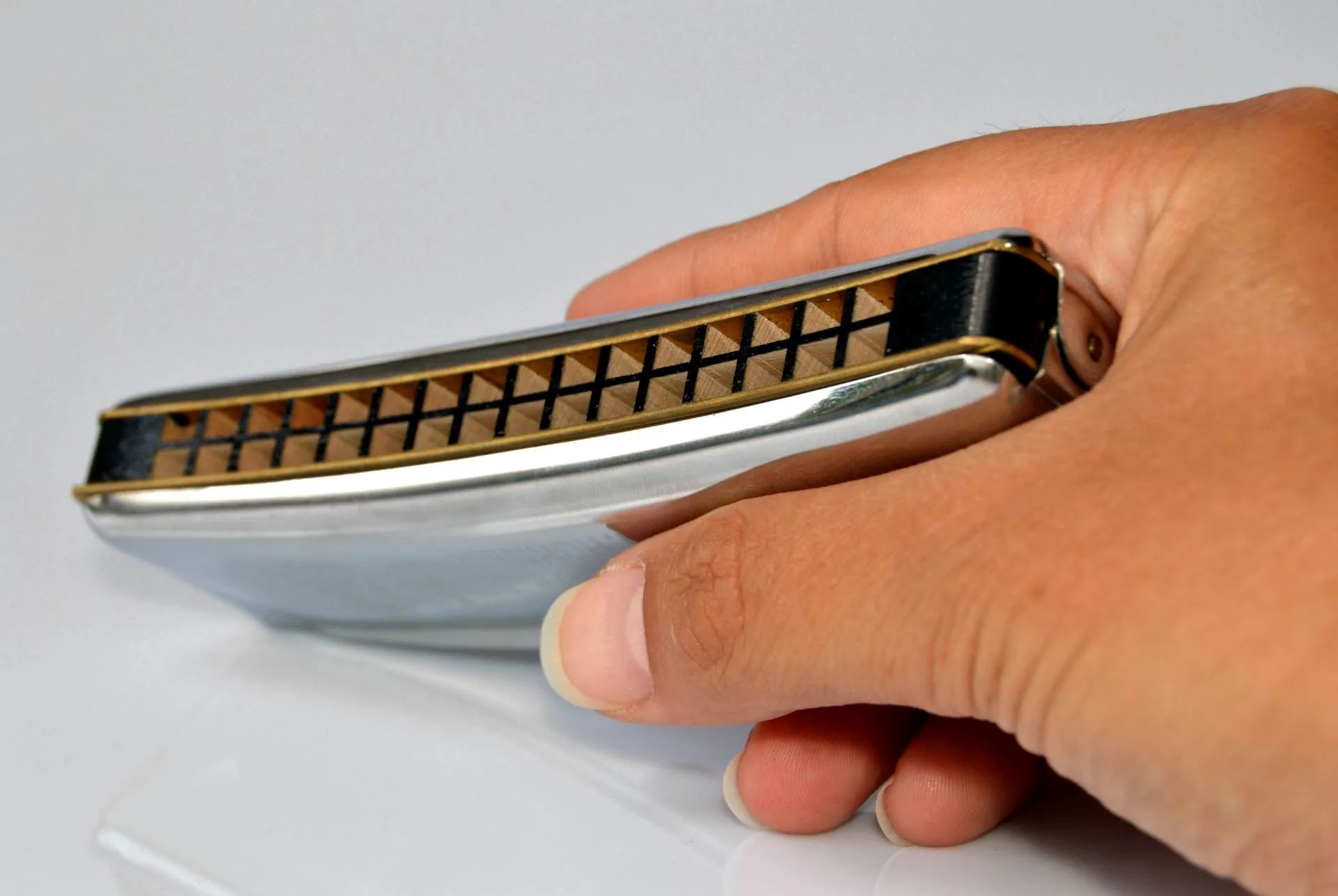

The harmonica, also known as a mouth organ or a harp, is a small and versatile musical instrument that has captured the hearts of music enthusiasts all over the world. It is a reed instrument that is played by blowing air into or drawing air out of the instrument through the channels and producing sound through vibrating metal reeds. The harmonica has a rich history and a unique charm that sets it apart from other musical instruments.

Since its invention in the early 19th century, the harmonica has found its way into various genres of music, including blues, folk, rock, country, and even classical music. It is a portable and expressive instrument that is loved and played by people of all ages and skill levels. Whether you’re a beginner learning to play your first notes or an experienced player showcasing your skills, the harmonica offers endless possibilities for creativity and expression.

In this article, we will explore the fascinating world of the harmonica, diving into its history, the materials used in its construction, the manufacturing process, tuning and assembly, quality control, and the packaging and distribution of this beloved instrument. Understanding the intricacies of how a harmonica is made will deepen our appreciation for its craftsmanship and the dedication that goes into creating these musical marvels.

So, grab your harmonica and get ready to embark on a journey through the inner workings of this iconic instrument. From its humble beginnings to its status as a universal symbol of musical expression, the harmonica continues to captivate and inspire musicians and enthusiasts around the globe.

History of the Harmonica

The harmonica has a rich and vibrant history that dates back centuries. Its origins can be traced back to ancient times, with the Chinese sheng and the Greek hydraulis serving as early predecessors. However, the harmonica as we know it today emerged in the early 19th century.

The credit for inventing the harmonica is often attributed to Christian Friedrich Ludwig Buschmann, a German clockmaker, who patented his design in 1821. His instrument, known as the “aura,” consisted of a series of tuned reeds mounted in a wooden mouthpiece, with a small bellows attached to create airflow.

However, it was a man named Matthias Hohner who truly popularized and revolutionized the harmonica. In 1857, Hohner, a German clockmaker and businessman, founded his harmonica company in Trossingen, Germany. He made significant advancements in harmonica design, including the addition of metal reeds, which improved durability and sound quality.

Throughout the years, the harmonica gained widespread popularity across continents. It became particularly prevalent in America during the mid-19th century, thanks to its portability and affordability. Harmonicas found their way into the hands of cowboys, miners, soldiers, and travelers, and it became an integral part of folk and blues music.

The harmonica gained iconic status in the blues genre, where it was used by legendary musicians like Sonny Boy Williamson, Little Walter, and Charlie Musselwhite. With its soulful sound and expressive capabilities, the harmonica played a crucial role in shaping the blues music scene and capturing the hearts of listeners worldwide.

Over the years, harmonica manufacturing techniques continued to evolve. Materials such as brass, stainless steel, and plastic were introduced, allowing for greater durability and tonal flexibility. The invention of the chromatic harmonica, with its ability to play all 12 notes of the Western musical scale, further expanded the instrument’s versatility.

Today, the harmonica remains a beloved musical instrument, cherished by professionals and amateurs alike. From the traditional diatonic harmonicas used in blues and folk music to the complex chromatic harmonicas used in jazz and classical music, the harmonica continues to captivate audiences with its unique sound and portability.

The history of the harmonica is a testament to the instrument’s enduring appeal and significance in the world of music. Its ability to evoke emotion, create melodies, and add a touch of soul to any performance has solidified its place as a cherished and timeless musical instrument.

Materials and Components Used in Harmonica Production

Harmonicas are meticulously crafted using a combination of high-quality materials and precise engineering. The choice of materials directly impacts the instrument’s durability, sound quality, and overall performance. Let’s delve into the key materials and components used in harmonica production.

1. Comb: The comb, also known as the body or the main housing, is the foundation of the harmonica. Traditionally, combs were made from wood, such as maple or pearwood, as it provides a warm and resonant tone. However, modern harmonicas often use plastic or metal combs for their durability and airtightness.

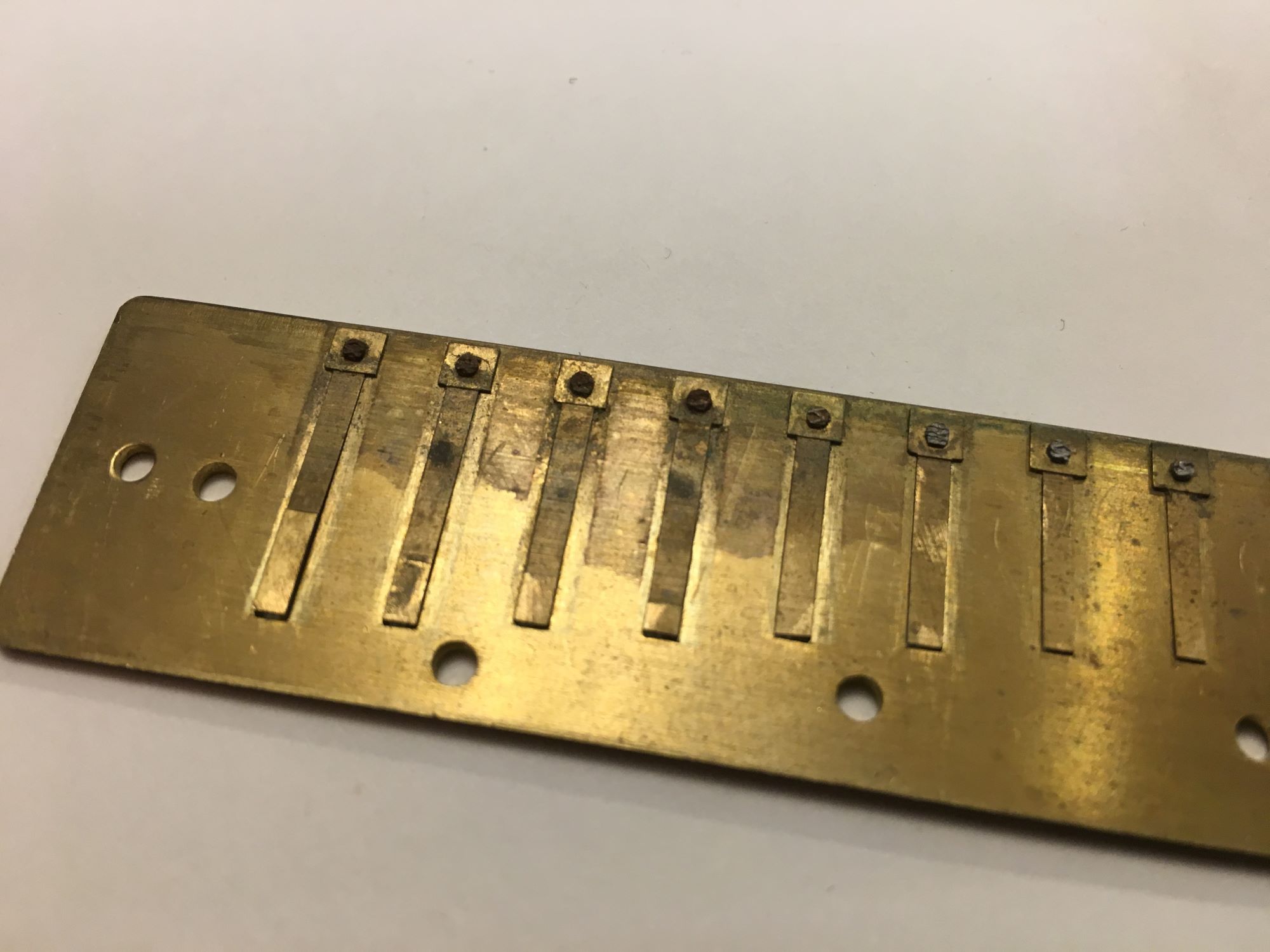

2. Reeds: The reeds are responsible for creating sound when air passes through them. Traditionally, reeds were made of brass, but modern harmonicas may use stainless steel or phosphor bronze for improved longevity and responsiveness. Each reed is precisely tuned to a specific pitch and is secured onto the comb.

3. Covers: The covers, also known as the plates or the top and bottom covers, are typically made of metal, usually stainless steel or brass. The covers encase the reeds and provide protection while allowing the player to direct airflow through specific channels. The design and shape of the covers also contribute to the instrument’s aesthetics.

4. Mouthpiece: The mouthpiece is the part of the harmonica that the player blows into or draws air from to produce sound. It is usually made of a non-toxic plastic material to ensure comfort and hygiene during playing.

5. Screws and Fasteners: Harmonicas are assembled using screws and fasteners made of durable materials, such as stainless steel. These components hold the reeds, covers, and the comb together, allowing for easy maintenance and repair.

6. Valves: Valves, also known as windsavers, are thin strips of material (often synthetic) attached to the reed plates. They control the direction of airflow, preventing air leakage and providing better control and responsiveness while playing.

7. Gaskets and Seals: Gaskets and seals are used to ensure an airtight seal between the comb, reed plates, and covers. They help optimize the instrument’s airtightness, which is crucial for producing clear and resonant sound.

8. Reed plates: The reed plates are thin metal plates that hold the individual reeds and are mounted on either side of the comb. They are typically made of high-quality stainless steel to withstand the constant vibrations of the reeds and ensure optimal sound transmission.

These are just a few of the key materials and components used in harmonica production. Skilled craftsmen and engineers meticulously select and assemble these parts to create harmonicas that offer exceptional playability, tone, and durability. Understanding these materials and components provides us with a deeper appreciation for the craftsmanship and engineering that goes into every harmonica.

Manufacturing Process of a Harmonica

The manufacturing process of a harmonica involves a series of intricate steps that require skilled craftsmanship and attention to detail. Let’s explore the key stages involved in bringing a harmonica to life.

1. Design and Planning: The process begins with designing the harmonica, taking into consideration factors such as the desired tonal range, key configurations, and overall aesthetics. Skilled designers and engineers work together to create harmonica models that meet the desired specifications.

2. Material Preparation: The selected materials, such as wood, metal, plastic, and reed stock, are prepared and shaped according to the harmonica model. Combs and reed plates are precision cut, sanded, and polished to ensure smooth surfaces and accurate dimensions.

3. Reed Production: The individual reeds are carefully cut from reed stock and shaped to specific lengths and widths. Skilled reed makers tune each reed to its designated pitch by adjusting its length and shape. The reeds are then secured onto the reed plates using specialized tools.

4. Comb Assembly: The comb, often made from a wooden or plastic material, undergoes meticulous shaping, sanding, and drilling to create the necessary channels for the reeds. The reed plates are precisely mounted on either side of the comb, ensuring a secure fit while maintaining an airtight seal.

5. Cover Production: The covers, typically made of metal, are fabricated by cutting, shaping, and polishing the cover material. Cutouts for the air channels and other design elements are carefully implemented. The covers are then plated or finished to enhance their appearance and provide protection against corrosion.

6. Tuning and Regulation: Once the harmonica is assembled, skilled craftsmen proceed to fine-tune the instrument. Using specialized tools and techniques, they ensure that each reed produces the desired pitch and responsiveness. Factors like reed gapping, wind savers, and air leakage are meticulously adjusted to optimize playability and sound quality.

7. Quality Control: The fully assembled harmonicas undergo a rigorous quality control process. Each harmonica is inspected to ensure proper reed alignment, airtightness, and overall functionality. Sound quality, responsiveness, and tone are also evaluated before the harmonicas are approved for packaging.

8. Final Inspection and Packaging: The harmonicas that pass the quality control process are carefully inspected one final time to ensure they meet the highest standards. The approved harmonicas are then cleaned, packaged, and prepared for distribution to retailers or customers.

Each stage of the manufacturing process requires skilled craftsmanship, precision, and attention to detail to create harmonicas that offer exceptional sound quality, playability, and durability. From material preparation to final inspection, every step contributes to the reputation and legacy of the harmonica as a cherished musical instrument.

Tuning and Assembly of a Harmonica

Tuning and assembly are crucial stages in the production of a harmonica, where skilled craftsmen meticulously fine-tune each reed and carefully assemble the various components to create a harmonica that produces exceptional sound quality and playability. Let’s explore the process of tuning and assembly in more detail.

Tuning: Tuning is the process of adjusting the pitch of each reed in the harmonica to ensure it produces the desired musical note. Skilled craftsmen use specialized tools and techniques to adjust the length, width, and curvature of each reed. By carefully removing or adding material to the reed, they can achieve the correct pitch and response. Tuning involves a delicate balance between achieving the desired pitch and maintaining the harmonica’s responsiveness and playability.

Assembly: The assembly process involves fitting together the various components of the harmonica to create a functional instrument. The comb, reed plates, and covers are precisely aligned and secured to each other to ensure an airtight seal. The reeds are mounted onto the reed plates, with careful consideration given to their location and alignment. Proper placement of the reeds allows for optimal vibration and sound production.

Skilled craftsmen pay close attention to the alignment of the reeds and adjust their positioning if necessary. The reed plates may be affixed to the comb using screws or other fasteners, ensuring a secure fit. The covers, often held in place by screws or clips, are installed over the reed plates, encasing the reeds and channels. The assembly process requires precision and expertise to guarantee functionality and airtightness.

Throughout the tuning and assembly process, craftsmen perform quality control checks to ensure consistent sound quality and playability. They test each reed individually, ensuring it responds accurately and produces the correct pitch. They also examine the harmonica’s airtightness, assessing for any potential air leakage that might affect its performance. Any adjustments or refinements necessary for optimal playability and sound quality are made during this stage.

Once the harmonica has passed the tuning and assembly stages, it undergoes thorough testing to ensure it meets the highest standards. Professional players, as well as quality control personnel, evaluate the harmonica’s playability, responsiveness, and overall sound quality. This final assessment ensures that every harmonica leaving the production line is of superior quality and ready for the joyous music-making journey that awaits.

By combining skilled craftsmanship, attention to detail, and a commitment to excellence, the tuning and assembly process transforms individual components into a harmonica that is capable of capturing hearts and inspiring musicians around the world.

Testing and Quality Control of a Harmonica

The testing and quality control stage is a critical part of harmonica production, ensuring that each instrument meets the highest standards of playability, sound quality, and durability. Skilled craftsmen and quality control personnel perform rigorous tests and inspections to identify any potential issues and ensure that only the finest harmonicas make their way into the hands of musicians. Let’s explore the testing and quality control process in more detail.

Visual Inspection: The harmonicas undergo a thorough visual inspection to identify any cosmetic defects or imperfections. This includes examining the finish of the covers, checking for uneven plating, scratches, or dents, and ensuring the overall aesthetics of the instrument meet the desired standards.

Airtightness: Achieving proper airtightness is crucial for optimal sound production. Each harmonica is tested to ensure that there are no air leaks, which could affect the instrument’s playability and tone. Skilled craftsmen check for proper contact between the reeds and the reed plates, as well as the alignment of parts to ensure an airtight seal.

Reed Responsiveness: The responsiveness of the reeds is assessed by skilled players or quality control personnel. They evaluate the speed and accuracy of the reeds’ response to airflow, ensuring that each note is produced with precision and clarity. Any reeds that are unresponsive or produce undesirable sounds are identified and adjusted accordingly.

Tuning Accuracy: Each reed is tested for pitch accuracy to ensure that the harmonica produces the correct notes when played. This involves carefully measuring and confirming that each reed is tuned to the desired pitch, following the designated musical scale and intonation. Any reeds that are out of tune are adjusted to achieve the correct pitch.

Sound Quality: Skilled musicians or quality control personnel play each harmonica to evaluate its overall sound quality. They assess factors like tone, clarity, projection, and tonal balance. The harmonica’s ability to produce a rich and expressive range of musical notes is closely scrutinized during this stage.

Playability and Comfort: The harmonicas are tested for playability and comfort, ensuring that they are easy to hold, manipulate, and play. Skilled musicians assess the harmonica’s ergonomics, evaluating factors like button responsiveness (in case of chromatic harmonicas), slide smoothness, mouth feel, and overall comfort during playing.

Durability and Finishing: Each harmonica is inspected for durability and finishing. This includes checking the stability of the components, the quality of the joint connections, and the overall build quality. Additionally, special attention is given to the materials used to ensure they are durable, long-lasting, and capable of withstanding the rigors of regular playing.

Through meticulous testing and quality control measures, harmonica manufacturers ensure that every instrument leaving their premises meets rigorous standards. This commitment to excellence guarantees that musicians receive harmonicas that deliver exceptional sound quality, playability, and longevity. Whether it’s for professional musicians, amateurs, or beginners, every harmonica undergoes a comprehensive quality control process before entering the market and finding its way into the hands of eager players.

Packaging and Distribution of Harmonicas

The packaging and distribution of harmonicas play a vital role in ensuring that these exquisite instruments reach musicians and enthusiasts worldwide in pristine condition. Let’s delve into the process of packaging and the journey harmonicas take from the manufacturing facility to the hands of eager players.

Packaging Design: Harmonica manufacturers invest significant effort in designing attractive and protective packaging for their products. The packaging not only serves as a means of transport but also as a showcase for the instrument. It typically includes a durable case or box that securely holds the harmonica, protecting it from impacts, moisture, and dust.

Protective Materials: Inside the packaging, the harmonica is often accompanied by a protective material, such as foam or velvet lining. These materials prevent the instrument from shifting during transportation and provide an extra layer of protection against scratches or other damage.

Labeling and Branding: The packaging is adorned with labels that display essential information about the harmonica, such as the brand name, model, and key. Additionally, it may showcase the manufacturer’s logo, promotional imagery, and instructions for care and maintenance.

Shipping and Distribution: Once packaged, harmonicas are prepared for shipping and distribution. They are carefully loaded onto pallets or placed in shipping containers, along with other harmonicas, to ensure safe transportation. Harmonica companies work closely with logistics partners to ensure the instruments are delivered efficiently to retailers and distributors around the world.

Retail Packaging: Retailers may choose to display harmonicas in specialized retail packaging. This could include blister packs, window boxes, or clamshell packaging with an attractive design that catches the eye of potential customers. Retail packaging often provides easy access to the harmonica for customers to try before purchase.

Online Distribution: With the rise of e-commerce, harmonicas are now widely distributed through online platforms. Manufacturers ship harmonicas directly from their facilities to customers who purchase them online. Care is taken to ensure secure packaging, protecting the instrument during transit and delivery.

Product Manuals and Accessories: Some harmonicas come with product manuals that provide guidance on playing techniques, maintenance, and care. Manufacturers may also include additional accessories, such as cleaning tools, spare reeds, or carrying cases, to enhance the playing experience and protect the instrument.

Throughout the packaging and distribution process, harmonica manufacturers prioritize the safety and integrity of their products. They work diligently to ensure that every harmonica is packaged securely, promoting its protection from damage and preserving its sound quality.

Whether shipped to retailers, distributors, or directly to customers’ doorsteps, harmonicas are carefully handled throughout the supply chain to maintain their pristine condition. The packaging and distribution process plays a significant role in ensuring that these beloved instruments arrive in the hands of musicians worldwide, ready to be played, cherished, and embraced for their soulful melodies.

Conclusion

The harmonica is a remarkable musical instrument that has captivated musicians and enthusiasts for centuries. From its humble origins to its modern-day complexity, the harmonica has evolved into a powerful tool for artistic expression across various musical genres.

Understanding the craftsmanship and artistry behind the harmonica’s production provides us with a deeper appreciation for this small but mighty instrument. The harmonica’s journey from design and planning to the meticulous tuning and assembly stages showcases the dedication and skill of the craftsmen involved in its creation. Every component, from the comb and reeds to the covers and valves, is meticulously crafted and assembled to create an exceptional instrument that can produce a wide range of musical notes and evoke a myriad of emotions.

Testing and quality control ensure that each harmonica meets the highest standards of playability, sound quality, and durability. Skilled individuals meticulously inspect and fine-tune every instrument, ensuring that it performs flawlessly and meets the expectations of musicians, whether they are beginners or experienced professionals.

From the precision tuning of the reeds to the airtight assembly of the components, each harmonica is created with a commitment to excellence. The harmonica’s unique sound and portability have made it a beloved musical companion for musicians around the world, offering endless possibilities for creative expression.

Through careful packaging and efficient distribution, harmonicas make their way into the hands of musicians and enthusiasts around the globe. A harmonica’s journey from the manufacturing facility to the end user involves protective packaging, labeling, and collaboration with logistics partners to ensure safe and timely delivery.

In conclusion, the harmonica is not only a musical instrument but a symbol of artistry, passion, and cultural significance. Its rich history, meticulous craftsmanship, and the dedication of those involved in its production are what continue to make this instrument a timeless favorite among musicians. So, whether you’re a seasoned player or someone looking to embark on a musical journey, embrace the harmonica’s enchanting melodies and let its soulful sound fill the air.