Home>Production & Technology>Soundproofing>What Fiberglass For Soundproofing

Soundproofing

What Fiberglass For Soundproofing

Published: January 27, 2024

Discover the best fiberglass materials for soundproofing your space and reducing unwanted noise. Enhance the tranquility of any room with effective soundproofing solutions.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for AudioLover.com, at no extra cost. Learn more)

Table of Contents

- Introduction

- Types of Fiberglass for Soundproofing

- Batt Insulation Fiberglass

- Blown-In Fiberglass

- Acoustic Fiberglass Panels

- Fiberglass Wool

- Factors to Consider

- Sound Transmission Class (STC) Rating

- Density

- Installation Method

- Fire Safety

- Benefits of Using Fiberglass for Soundproofing

- Effective Noise Reduction

- Thermal Insulation

- Cost-Effective Solution

- Versatile Application

- Tips for Using Fiberglass for Soundproofing

- Proper Installation

- Using the Right Thickness

- Sealing Air Gaps

- Regular Maintenance

- Conclusion

Introduction

Soundproofing is a crucial aspect of creating a peaceful and comfortable environment, whether it’s in your home, office, or any other space. Excessive noise can be distracting, stressful, and detrimental to overall well-being. That’s where soundproofing materials come into play, and one of the most popular options is fiberglass.

Fiberglass is a synthetic material made from extremely fine glass fibers, which are woven together to form flexible sheets or panels. Its unique composition makes it an excellent choice for soundproofing because it effectively absorbs and dampens sound waves, reducing noise transmission through walls, ceilings, and floors.

In this article, we will explore the different types of fiberglass commonly used for soundproofing and discuss the factors to consider when selecting the right fiberglass for your specific needs. We will also highlight the benefits of using fiberglass for soundproofing and provide some useful tips for proper installation and maintenance.

So, if you’re looking to create a quieter and more peaceful space, read on to discover how fiberglass can be your go-to solution for effective soundproofing.

Types of Fiberglass for Soundproofing

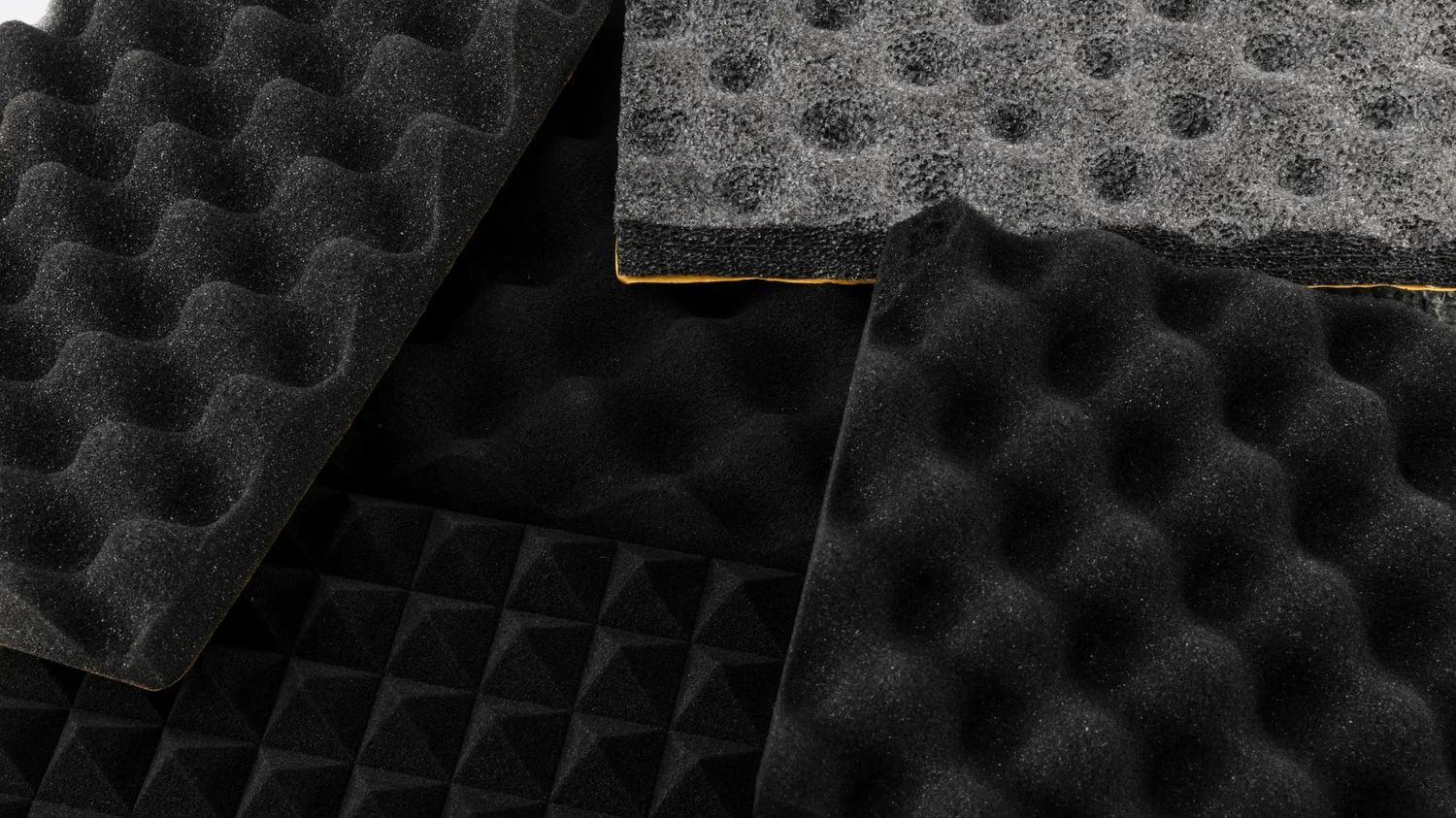

When it comes to soundproofing with fiberglass, there are several options available, each with its own unique characteristics and applications. Let’s take a closer look at some of the most common types:

- Batt Insulation Fiberglass: This is the most widely used type of fiberglass for soundproofing. It comes in pre-cut sheets or rolls, known as batts, making it easy to install between wall studs, ceiling joists, and floorboards. Batt insulation fiberglass is highly effective at reducing airborne noise and has good thermal insulation properties.

- Blown-In Fiberglass: Also known as loose-fill fiberglass, this type is typically used in enclosed spaces, such as attics and wall cavities. It consists of small strands of fiberglass that are carefully blown into the desired area using specialized equipment. Blown-in fiberglass creates a dense layer that effectively absorbs sound and provides insulation.

- Acoustic Fiberglass Panels: These panels are specifically designed for soundproofing purposes. They are thicker and denser than regular fiberglass panels, providing excellent sound absorption properties. Acoustic fiberglass panels are commonly used in recording studios, theaters, and other environments where precise control over sound is required.

- Fiberglass Wool: Also known as mineral wool, this type of fiberglass is made by spinning molten glass fibers into a bulky mass. It is often used in areas where high thermal and acoustic insulation is needed, such as industrial buildings or soundproofing partitions. Fiberglass wool is highly versatile and easy to handle, making it ideal for various soundproofing applications.

These different types of fiberglass can be applied in various ways depending on the specific soundproofing requirements of your space. Now that we have an understanding of the different options available, let’s explore the key factors to consider when choosing the right fiberglass for your soundproofing project.

Batt Insulation Fiberglass

Batt insulation fiberglass is a popular choice for soundproofing due to its ease of installation and effectiveness in reducing airborne noise. It is available in pre-cut sheets or rolls, making it convenient to fit between wall studs, ceiling joists, and floorboards.

The key feature of batt insulation fiberglass is its ability to absorb sound waves, preventing them from traveling through walls and other surfaces. The density of the fiberglass material contributes to its soundproofing capabilities, as denser fibers can better trap and dampen sound vibrations.

When installing batt insulation fiberglass for soundproofing purposes, it is important to ensure a proper fit. Gaps or spaces between the insulation and the surrounding structure can significantly reduce its effectiveness. It is recommended to measure and cut the insulation material accurately to ensure complete coverage and minimal air leakage.

Batt insulation fiberglass not only helps in reducing noise transmission but also offers thermal insulation benefits. It helps to maintain a comfortable temperature inside a room by preventing heat transfer through walls and floors.

One important aspect to consider when using batt insulation fiberglass is its Sound Transmission Class (STC) rating. The STC rating measures the material’s ability to reduce sound transmission at different frequencies. The higher the STC rating, the better the soundproofing performance. When selecting batt insulation fiberglass, look for a higher STC rating to ensure optimal noise reduction.

Overall, batt insulation fiberglass is a versatile and cost-effective option for soundproofing walls, ceilings, and floors. Its ease of installation, effective sound absorption properties, and additional thermal insulation benefits make it a popular choice for both residential and commercial applications.

Blown-In Fiberglass

Blown-in fiberglass, also known as loose-fill fiberglass, is an excellent option for soundproofing enclosed spaces such as attics and wall cavities. This type of fiberglass consists of small strands that are blown into the desired area using specialized equipment.

Blown-in fiberglass creates a dense layer of insulation that effectively absorbs and dampens sound waves. The loose-fill nature of the fibers allows them to conform to irregular shapes and fill in gaps and crevices, reducing the chances of sound leakage. This makes it particularly effective at reducing both airborne noise and impact noise.

One of the key advantages of blown-in fiberglass is its ability to provide consistent coverage in hard-to-reach areas. The blown-in technique allows the fibers to reach areas that may be inaccessible or difficult to reach with other types of insulation materials. This makes it a popular choice for retrofitting soundproofing in existing structures.

When considering blown-in fiberglass for soundproofing, it is important to ensure proper installation by an experienced professional. The density and distribution of the fibers need to be carefully controlled to achieve optimal soundproofing performance. Improper installation can lead to uneven insulation coverage and compromised soundproofing effectiveness.

Blown-in fiberglass not only offers soundproofing benefits but also provides thermal insulation. It helps to reduce heat transfer, keeping the interior space comfortable and energy-efficient. By improving the insulation performance, blown-in fiberglass can contribute to energy savings and reduce heating and cooling costs.

Overall, blown-in fiberglass is a versatile and effective option for soundproofing enclosed spaces. Its ability to fill gaps, reach inaccessible areas, and provide consistent coverage makes it an ideal choice for retrofitting projects. Consider using blown-in fiberglass to effectively reduce noise transmission and improve the acoustic comfort of your space.

Acoustic Fiberglass Panels

Acoustic fiberglass panels are specifically designed to provide excellent soundproofing capabilities in environments where precise control over sound is necessary. These panels are thicker and denser than regular fiberglass panels, allowing them to effectively absorb sound waves and reduce reverberation.

Acoustic fiberglass panels are commonly used in recording studios, theaters, concert halls, and other spaces where sound quality and clarity are paramount. They are available in various sizes and shapes, allowing for versatile installation options to suit different room configurations and acoustic requirements.

The dense composition of acoustic fiberglass panels enables them to absorb a wide range of frequencies, from low to high. This ensures that excessive echoes and reverberation are minimized, leading to improved sound quality and clarity within a space. By reducing sound reflections, these panels can help create a more controlled and optimized acoustic environment.

Installing acoustic fiberglass panels requires careful consideration of placement and coverage. Strategic placement on walls and ceilings can help optimize sound absorption and minimize sound transmission. It is essential to cover a sufficient amount of surface area to achieve the desired soundproofing results.

One of the advantages of acoustic fiberglass panels is their aesthetic appeal. They can be covered with attractive fabric or vinyl finishes that not only enhance their visual appeal but also provide additional sound diffusion properties. This allows for a customized and visually pleasing installation that blends seamlessly with the overall design of the space.

In addition to their soundproofing capabilities, acoustic fiberglass panels also offer thermal insulation benefits. They can help regulate temperature and improve energy efficiency by reducing heat transfer through walls and ceilings.

Whether you’re setting up a home recording studio or creating a cinema-like experience in your media room, acoustic fiberglass panels are an excellent choice for achieving superior soundproofing. Their ability to absorb sound, reduce reverberation, and enhance the overall acoustic environment makes them a go-to solution for professionals and enthusiasts alike.

Fiberglass Wool

Fiberglass wool, also known as mineral wool, is a type of fiberglass made by spinning molten glass fibers into a bulky mass. It is widely used for soundproofing and insulation purposes in various applications, including industrial buildings, residential spaces, and soundproofing partitions.

The construction of fiberglass wool involves creating a web of interlocking fibers, resulting in a material with high thermal and acoustic insulation properties. Its fibrous structure allows it to trap and absorb sound waves, effectively reducing noise transmission through walls, floors, and ceilings.

One of the key advantages of fiberglass wool is its versatility. It comes in various forms, including rolls, batts, and loose-fill. These different forms allow for flexible installation based on the specific soundproofing requirements of a space. Fiberglass wool can be easily cut to fit between studs or inserted into wall cavities, making it ideal for both new construction and retrofitting projects.

Fiberglass wool’s thermal insulation properties are equally important. It effectively reduces heat transfer through walls and other surfaces, helping to maintain a comfortable and energy-efficient indoor environment. By improving thermal insulation, fiberglass wool can contribute to energy savings and reduce heating and cooling costs.

One of the considerations when using fiberglass wool is the density of the material. The density affects both its soundproofing and thermal insulation performance. Higher density fiberglass wool generally provides better sound absorption and thermal insulation properties. However, it is essential to strike a balance between density and ease of installation to ensure proper functionality.

When working with fiberglass wool, it is crucial to follow proper safety precautions. Fiberglass particles can cause skin irritation, so wearing protective clothing and gloves is recommended during handling and installation. Additionally, using a face mask or respirator can prevent inhalation of airborne fibers.

Fiberglass wool is a widely used and effective solution for soundproofing and insulation. Its versatility, cost-effectiveness, and excellent performance in reducing noise transmission and providing thermal insulation make it a popular choice for various applications.

Factors to Consider

When selecting fiberglass for soundproofing, there are several important factors to consider. These factors will help you choose the right type and determine the effectiveness of the fiberglass for your specific soundproofing needs. Here are the key factors to keep in mind:

- Sound Transmission Class (STC) Rating: The STC rating measures the ability of a material to reduce sound transmission. Look for fiberglass with a higher STC rating for better soundproofing performance.

- Density: The density of fiberglass affects its sound absorption and thermal insulation capabilities. Generally, higher density fiberglass provides better soundproofing, but it’s important to strike a balance with ease of installation.

- Installation Method: Consider the installation method required for the specific type of fiberglass. Some fiberglass may be easily installed in batts or rolls, while others may require professional blowing or panel installation.

- Fire Safety: Verify that the fiberglass material you choose meets fire safety standards. Look for products that are fire-resistant or have a good fire rating for added safety.

By considering these factors, you can ensure that the fiberglass you select will effectively reduce noise transmission and meet your soundproofing goals. Keep in mind that consulting with a professional soundproofing expert can provide valuable guidance and help you make an informed decision.

Sound Transmission Class (STC) Rating

The Sound Transmission Class (STC) rating is a crucial factor to consider when selecting fiberglass for soundproofing. The STC rating measures the ability of a material to reduce the transmission of sound through a barrier. It provides a standardized way of comparing the soundproofing performance of different materials.

The STC rating is determined by conducting laboratory tests that measure how much sound a particular material can block across a range of frequencies. The higher the STC rating, the better the material is at reducing sound transmission.

When choosing fiberglass for soundproofing, look for products with a high STC rating to ensure effective noise reduction. Fiberglass products with STC ratings of 50 or above are considered to provide excellent soundproofing capabilities, effectively blocking the transmission of most common noises.

It is important to note that the STC rating is an average rating across a range of frequencies. Different materials can have different performance levels at different frequencies. If you have specific noise frequency concerns, consider selecting fiberglass products with STC ratings that target those frequencies.

Keep in mind that achieving higher STC ratings often requires increased density and thickness of the fiberglass material. While higher density fiberglass generally provides better soundproofing, it is important to find a balance between density and ease of installation. In some cases, adding additional layers of lower density fiberglass can be an effective way to improve the overall sound transmission reduction.

It’s worth noting that the STC rating measures sound transmission through a barrier. To achieve optimal soundproofing, it is important to address other weak points in the room, such as gaps around doors and windows or air vents, as sound can easily travel through these openings. Proper installation and sealing of the fiberglass material, along with addressing other potential sound leakage points, will maximize the effectiveness of the soundproofing solution.

In summary, when choosing fiberglass for soundproofing, pay attention to the STC rating of the material. Aim for higher STC ratings to ensure effective noise reduction. Consider the density and thickness of the fiberglass, and also address other potential sound leakage points in the room to achieve optimal soundproofing results.

Density

The density of fiberglass is an important factor to consider when selecting a material for soundproofing. The density refers to the mass per unit volume of the fiberglass, and it plays a significant role in determining its sound absorption and insulation properties.

In general, higher density fiberglass tends to provide better soundproofing. This is because the denser fibers are more effective at absorbing sound waves, preventing them from passing through walls, ceilings, or floors. The density of fiberglass is typically measured in pounds per cubic foot (pcf) or kilograms per cubic meter (kg/m³).

When sound waves encounter high-density fiberglass, they are absorbed and converted into heat energy. This reduces the level of noise transmission, resulting in a quieter and more peaceful environment. Higher density fiberglass is particularly effective at reducing low-frequency sounds, such as bass or rumbling noises.

However, it is important to find the right balance between density and ease of installation. While higher density fiberglass generally provides better soundproofing performance, it can also be more challenging to handle and install. Higher density fiberglass may require additional support or framing to ensure proper installation and stability.

On the other hand, lower density fiberglass may be easier to handle and install, but it may have reduced soundproofing effectiveness. Lower density fiberglass may not absorb as much sound energy, allowing more noise to pass through the material. This can be a consideration when selecting fiberglass for soundproofing in areas where noise reduction is critical, such as recording studios or bedrooms.

Ultimately, the density of fiberglass should be chosen based on the specific requirements of the soundproofing project. Consider the level of noise reduction needed, the frequency range of the noise, and the ease of installation. Consulting with professionals or experts in soundproofing can help determine the appropriate density of fiberglass for optimal soundproofing performance.

In summary, the density of fiberglass is an important consideration for soundproofing. Higher density fiberglass generally provides better sound absorption and noise reduction. However, it is crucial to find the right balance between density and ease of installation to ensure a successful soundproofing solution.

Installation Method

The installation method of fiberglass is an important factor to consider when planning a soundproofing project. Different types of fiberglass require different installation techniques, and choosing the right method is essential for achieving optimal soundproofing results.

For batt insulation fiberglass, the most common installation method is fitting the pre-cut sheets or rolls between wall studs, ceiling joists, or floorboards. This method is relatively straightforward and can be done as a do-it-yourself project. It is important to ensure proper coverage and a tight fit to minimize air gaps, as these can compromise the effectiveness of the soundproofing.

Blown-in fiberglass, on the other hand, requires specialized equipment for installation. The loose-fill fiberglass is blown into wall cavities or attics, filling the spaces and creating a dense layer. Professional installation is often recommended to ensure even distribution and proper coverage. This method is ideal for existing structures or areas where it may be difficult to install batt insulation.

Acoustic fiberglass panels are typically installed by mounting them directly onto walls or ceilings. They can be attached using adhesive or mechanical fasteners, depending on the specific panel design. It is important to follow the manufacturer’s instructions and ensure proper installation to achieve maximum soundproofing performance. In some cases, professional assistance may be required to ensure precise and secure installation.

For fiberglass wool, the installation method varies depending on the specific form of the material. It can be installed as rolls, batts, or loose-fill, depending on the area and soundproofing requirements. Insulation material is typically placed between studs or inserted into wall cavities, ensuring complete coverage and minimal air leakage.

When considering the installation method, it’s important to evaluate your own skills and capabilities. Some installation methods may require professional assistance for proper execution. Hiring a soundproofing professional can ensure that the fiberglass is installed correctly and that the desired soundproofing goals are met.

In summary, consider the installation method required for the specific type of fiberglass you are using. Evaluate your own capabilities and determine if professional installation is needed. Proper installation is crucial for achieving optimal soundproofing performance, so it’s important to choose the method that best suits your project and resources.

Fire Safety

When selecting fiberglass for soundproofing, it is crucial to consider its fire safety properties. Fire safety is a critical aspect in any building or space, and using fire-resistant materials can help enhance overall safety and compliance with fire codes and regulations.

Not all fiberglass products are created equal when it comes to fire safety. It’s important to choose fiberglass that meets recognized fire safety standards and has appropriate fire ratings. Look for fiberglass that is specifically labeled as fire-resistant or has undergone fire testing to ensure its reliability in fire-prone environments.

Fiberglass with good fire resistance will have properties that contribute to preventing the spread of flames, limiting the release of harmful smoke and toxins, and minimizing the risk of fire-related damage. These properties are particularly important in areas where fire safety is critical, such as commercial buildings, schools, hospitals, or high-rise structures.

When using fiberglass for soundproofing, it is important to ensure that the material is properly installed and does not create any fire hazards. Avoid situations where fiberglass is exposed to open flames or ignition sources. Take care not to compress the fiberglass tightly against hot surfaces, as this can compromise its fire resistance.

By selecting fire-resistant fiberglass and ensuring proper installation and maintenance, you can help minimize the risk of fire and enhance the safety of your space. When in doubt, consult with professionals who specialize in fire safety and soundproofing to ensure that the chosen fiberglass meets all necessary fire safety requirements.

In summary, fire safety is a crucial consideration when selecting fiberglass for soundproofing. Choose fiberglass that is labeled as fire-resistant or has undergone fire testing to ensure its reliability. Proper installation and maintenance are also important in maintaining the fire resistance of the fiberglass material.

Benefits of Using Fiberglass for Soundproofing

Soundproofing is an essential consideration for creating a peaceful and comfortable environment in various settings. Fiberglass is a popular choice for soundproofing due to its numerous benefits. Let’s explore the advantages of using fiberglass for soundproofing:

- Effective Noise Reduction: Fiberglass is highly effective at absorbing and dampening sound waves, reducing noise transmission through walls, floors, and ceilings. It helps create a quieter and more peaceful atmosphere, minimizing distractions and improving overall comfort.

- Thermal Insulation: Along with its soundproofing properties, fiberglass also offers thermal insulation benefits. It helps regulate temperature by reducing heat transfer through walls and floors, leading to better energy efficiency and cost savings.

- Cost-Effective Solution: Fiberglass is a cost-effective soundproofing solution compared to other materials. It is readily available in various forms and can be easily installed, making it an affordable option for both residential and commercial applications.

- Versatile Application: Fiberglass can be used in a wide range of spaces, including homes, offices, studios, theaters, and industrial areas. It is suitable for retrofitting existing structures or incorporating into new construction projects.

In addition to these benefits, fiberglass also has excellent durability, allowing it to withstand wear and tear over time. It is resistant to mold and mildew growth, making it a hygienic choice for soundproofing applications.

Fiberglass is also a versatile material that can be easily customized to suit specific soundproofing needs. It can be cut and shaped to fit different areas and can be combined with other materials for enhanced soundproofing performance.

Moreover, fiberglass is an environmentally friendly soundproofing option. It is made from recyclable materials and can be recycled at the end of its life cycle, reducing waste and promoting sustainability.

Overall, the benefits of using fiberglass for soundproofing make it a popular choice among homeowners, architects, and contractors. Its effective noise reduction, thermal insulation properties, cost-effectiveness, versatility, and eco-friendliness make it a reliable solution for creating quieter and more comfortable spaces.

Effective Noise Reduction

One of the primary benefits of using fiberglass for soundproofing is its exceptional ability to reduce noise transmission. Fiberglass is highly effective at absorbing and dampening sound waves, making it an ideal material for creating quiet and peaceful environments.

When sound waves encounter fiberglass, they pass through the material and their energy is converted into heat. This process, known as sound absorption, helps to reduce the intensity and volume of noise. The dense composition of fiberglass fibers allows for efficient sound absorption across a wide range of frequencies.

Fiberglass is particularly effective at reducing airborne noise, such as conversations, music, or traffic sounds. It helps to prevent sound waves from passing through walls, ceilings, and floors, minimizing noise leakage and maintaining privacy within a space.

Whether you want to reduce noise from outside sources like traffic or neighbors, or you need to contain noise within a specific area, fiberglass can significantly contribute to noise reduction. It is commonly used in residential buildings, office spaces, recording studios, theaters, and other environments where noise control is crucial.

In addition to its ability to reduce airborne noise, fiberglass is also effective at absorbing impact noise, which includes footsteps, door slams, or vibrating equipment. By reducing impact noise, fiberglass helps to create a more peaceful and tranquil environment.

It’s important to note that the effectiveness of fiberglass in noise reduction depends on factors such as the thickness, density, and installation method of the material. Thicker and denser fiberglass generally provides better soundproofing performance. Proper installation, ensuring complete coverage and minimizing air gaps, is also essential to maximize the noise reduction capabilities of fiberglass.

Overall, fiberglass’s effectiveness in noise reduction makes it an excellent choice for soundproofing various spaces. Whether it’s creating a quieter bedroom for better sleep, blocking out external noise in an office, or enhancing sound quality in a recording studio, fiberglass can significantly contribute to a more peaceful and comfortable environment.

Thermal Insulation

In addition to its soundproofing properties, fiberglass also offers significant thermal insulation benefits. This means that it helps to regulate temperature by reducing heat transfer through walls, floors, and ceilings, resulting in improved energy efficiency and increased comfort.

Fiberglass acts as a barrier against heat flow, preventing the transfer of thermal energy between different areas. It does this by trapping pockets of air within its structure, which act as insulating pockets. These air pockets slow down the movement of heat, reducing heat conduction and helping to maintain a stable and comfortable indoor temperature.

By installing fiberglass insulation in walls, ceilings, and floors, you can minimize heat loss during cold seasons and reduce heat gain during hot seasons. This results in better temperature control and reduced dependence on heating and cooling systems, leading to energy savings and lower utility bills.

Moreover, the thermal insulation provided by fiberglass can contribute to a more consistent and comfortable living or working environment. It helps to reduce temperature fluctuations, creating a space that is pleasant to inhabit all year round.

Fiberglass insulation is especially beneficial in areas with extreme climates or in buildings with improper insulation. It can help to bridge gaps, seal air leaks, and maintain a more even temperature throughout the space.

Additionally, fiberglass insulation can contribute to reducing the carbon footprint of a building. By improving energy efficiency, it reduces the amount of energy needed for heating and cooling, resulting in reduced greenhouse gas emissions.

It is important to note that the thermal insulation performance of fiberglass is influenced by factors such as thickness, density, and proper installation. Thicker and denser fiberglass generally provide better thermal insulation properties. Ensuring a complete and proper installation without any gaps or compression is essential for maximizing thermal insulation effectiveness.

Overall, the thermal insulation benefits of fiberglass make it an excellent addition to any soundproofing project. By reducing heat transfer and improving energy efficiency, fiberglass insulation can create a more comfortable and environmentally friendly living or working space.

Cost-Effective Solution

One significant advantage of using fiberglass for soundproofing is its cost-effectiveness. Compared to other soundproofing materials, fiberglass offers a practical and budget-friendly solution without compromising on performance.

Fiberglass is readily available and widely manufactured, making it a cost-effective option for soundproofing projects. It can be found in various forms, including batt insulation, blown-in, acoustic panels, and fiberglass wool, catering to different installation requirements and budget constraints.

The affordability of fiberglass extends beyond its initial purchase cost. Fiberglass is relatively easy to install, making it suitable for do-it-yourself projects. This can potentially save significant installation expenses, as professional installation may not be necessary for experienced homeowners or individuals with basic construction skills.

In addition to the material cost and ease of installation, fiberglass requires minimal maintenance, further contributing to its cost-effectiveness. Once installed, it typically does not require any special upkeep or regular attention. This means that the long-term costs associated with fiberglass soundproofing are minimal compared to other soundproofing alternatives that may require recurring maintenance or replacement.

By opting for fiberglass, you can achieve effective noise reduction without breaking the bank. This makes it an attractive solution for homeowners, businesses, and organizations that want to improve acoustic comfort while staying within their budget constraints.

It is worth noting that the overall cost of implementing fiberglass for soundproofing can vary depending on factors such as the size of the space, the type and thickness of fiberglass used, and any additional soundproofing materials or techniques incorporated. Consider consulting with soundproofing professionals who can provide accurate cost estimates based on your specific project requirements.

In summary, fiberglass is a cost-effective choice for soundproofing projects. Its affordability, ease of installation, low maintenance requirements, and effective noise reduction capabilities make it an accessible option for individuals and organizations looking for a cost-conscious yet efficient soundproofing solution.

Versatile Application

One of the key benefits of using fiberglass for soundproofing is its versatility in application. Fiberglass can be used in a wide range of spaces and structures, offering flexibility and adaptability to various soundproofing needs.

Residential buildings, commercial spaces, educational institutions, recording studios, theaters, industrial facilities, and more can all benefit from the versatile application of fiberglass for soundproofing.

Fiberglass is available in different forms, including batt insulation, blown-in, acoustic panels, and fiberglass wool. Each form is suitable for specific applications and installation methods:

- Batt insulation: Ideal for fitting between wall studs, ceiling joists, or floorboards, making it suitable for new construction, remodeling, or retrofitting projects.

- Blown-in: Especially useful for insulating enclosed spaces such as attics or wall cavities, where traditional batt insulation may be difficult to install.

- Acoustic panels: Designed specifically for soundproofing purposes, they can be mounted on walls or ceilings to optimize sound absorption in recording studios, theaters, and other spaces where precise control over sound is required.

- Fiberglass wool: Highly versatile and available in various forms, including rolls, batts, or loose-fill, making it suitable for different soundproofing applications and areas.

Furthermore, fiberglass can be easily cut, shaped, and customized to fit specific areas and unique soundproofing requirements. It can be used in combination with other materials to enhance soundproofing performance or complement various interior design styles.

Whether you’re soundproofing a single room, an entire building, or a specific piece of equipment, fiberglass provides ample options and flexibility to suit your needs. Its versatility enables you to create acoustic comfort in different settings and customize soundproofing solutions to meet specific requirements.

When considering fiberglass for soundproofing, it is advisable to consult with soundproofing experts or professionals. They can assess your specific needs and provide guidance on the most suitable form of fiberglass and installation techniques for optimal soundproofing performance.

In summary, fiberglass’s versatility in application makes it a practical choice for soundproofing various spaces and structures. Its availability in different forms and the ability to customize its use allow for tailored soundproofing solutions that address specific needs and requirements.

Tips for Using Fiberglass for Soundproofing

When utilizing fiberglass for soundproofing purposes, there are several essential tips to keep in mind to ensure optimal performance and effectiveness. These tips will help you achieve the best results with your fiberglass soundproofing installation:

- Proper Installation: Ensure that the fiberglass is installed correctly and securely. Follow the manufacturer’s instructions and guidelines for the specific type of fiberglass you are using. Improper installation can compromise the soundproofing capabilities of the material.

- Using the Right Thickness: Select the appropriate thickness of fiberglass for your specific needs. Thicker fiberglass generally offers better sound absorption properties, especially for low-frequency sounds. Consider consulting with professionals to determine the optimal thickness for your soundproofing project.

- Sealing Air Gaps: Pay attention to sealing any air gaps around windows, doors, electrical outlets, and other potential sound leakage points. Even the highest quality fiberglass will not be fully effective if there are gaps that allow sound to pass through.

- Regular Maintenance: Periodically check the condition of the fiberglass and ensure it remains in good shape. Inspect for any signs of damage, such as tears or compression. Address any issues promptly to maintain the soundproofing performance.

It is important to note that fiberglass should be handled with care to prevent potential health hazards. When working with fiberglass, wear protective clothing, gloves, and a mask to avoid contact with the fine fibers and to prevent inhalation.

Professional assistance can be invaluable when it comes to installing fiberglass for soundproofing. Soundproofing experts have the knowledge and experience to guide you through the process, ensuring proper installation and maximizing the soundproofing benefits of the fiberglass.

Remember, the effectiveness of fiberglass for soundproofing relies not only on the material itself but also on other factors such as proper installation, addressing air gaps, and regular maintenance. By following these tips and consulting with professionals, you can create a more peaceful and soundproofed environment using fiberglass.

Proper Installation

Proper installation is crucial for maximizing the soundproofing effectiveness of fiberglass. Ensuring the correct installation techniques will help create a barrier that effectively absorbs and reduces noise transmission. Here are some key tips for achieving proper fiberglass installation:

Measure and Cut Accurately: Take precise measurements of the space where the fiberglass will be installed. Cut the fiberglass material accurately to fit the dimensions, ensuring complete coverage without leaving any gaps or overlaps. This will help prevent sound from leaking through openings or unprotected areas.

Securely Fit the Fiberglass: Place the fiberglass securely between wall studs, ceiling joists, or floorboards, depending on the specific installation area. Ensure a tight fit so that there are no air gaps that can compromise the soundproofing capabilities of the material.

Seal with Acoustic Sealant: Use acoustic sealant to seal any gaps or seams between the fiberglass and the surrounding surfaces. This will prevent sound from leaking through small openings and enhance the overall soundproofing performance of the fiberglass.

Prioritize Wall Cavities: Pay close attention to insulating wall cavities, as they can be major contributors to sound leakage. Fill the wall cavities with fiberglass insulation, ensuring complete coverage and avoiding compression that can reduce its soundproofing effectiveness.

Consider Professional Installation: If you are unsure about the proper installation techniques or if the project involves complex or hard-to-reach areas, consider hiring professionals who specialize in soundproofing. They have the expertise and experience to ensure the fiberglass is installed correctly and effectively.

Remember to follow safety guidelines when handling fiberglass. Wear appropriate protective equipment such as gloves, long sleeves, and a mask to avoid contact with the fine fibers, which can cause irritation.

By focusing on proper installation techniques, you can optimize the soundproofing capabilities of fiberglass, creating a quieter and more peaceful environment in your space.

Using the Right Thickness

Choosing the right thickness of fiberglass is essential for achieving effective soundproofing. The thickness of the fiberglass material directly impacts its ability to absorb sound waves and reduce noise transmission. Here are some key considerations when selecting the appropriate thickness:

Sound Frequency: Different frequencies of sound require different thicknesses of fiberglass to effectively absorb and reduce noise. Low-frequency sounds, such as heavy bass or rumbling noises, typically require thicker fiberglass to achieve optimal soundproofing. Higher frequencies may be effectively absorbed with relatively thinner fiberglass.

STC Rating Requirements: Consider the required Sound Transmission Class (STC) rating for your soundproofing project. The STC rating measures the material’s ability to block sound transmission. Higher STC ratings usually require thicker fiberglass for better noise reduction.

Space Limitations: Evaluate the available space for fiberglass installation. In some cases, space limitations may restrict the thickness of the fiberglass that can be used. Consider the dimensions of the area where the fiberglass will be installed to ensure a proper fit and coverage.

Consult with Professionals: When in doubt, seek guidance from soundproofing professionals. They can assess your specific soundproofing needs, evaluate the desired noise reduction levels, and recommend the appropriate thickness of fiberglass for optimal soundproofing performance.

Balancing Thickness and Installation: Remember to strike a balance between the thickness of the fiberglass and ease of installation. Thicker fiberglass generally provides better soundproofing, but it may be more challenging to handle and install. Consider factors such as available space, access to the installation area, and any structural considerations that may affect the thickness of fiberglass that can be used.

Keep in mind that the thickness of the fiberglass is just one factor in achieving effective soundproofing. Proper installation techniques, such as ensuring a secure fit and sealing any gaps, are equally important for optimal soundproofing performance.

By selecting the right thickness of fiberglass for your specific project requirements, you can maximize its sound-absorbing capacity and create a quieter and more peaceful environment in your space.

Sealing Air Gaps

Sealing air gaps is a crucial step in the soundproofing process when using fiberglass. Even the highest quality fiberglass can be rendered less effective if there are openings or gaps that allow sound to pass through. Here are some important tips for sealing air gaps:

Identify Potential Air Leakage Points: Inspect the area where the fiberglass is being installed and identify potential gaps or openings that could allow sound to leak. Common areas to pay attention to include windows, doors, electrical outlets, vents, and any seams or joints in the construction.

Use Acoustic Sealant: Acoustic sealant is specially designed to fill in gaps and cracks and prevent sound transmission. Apply the sealant around windows and doors, along the baseboards, and around any openings in walls or ceilings. Be sure to use a sealant that is compatible with the materials used in your construction to ensure proper adhesion and durability.

Address Gaps Between Fiberglass Sheets: If you are using fiberglass batts or panels that are installed in sections, pay close attention to the gaps between each piece. Seal any gaps using acoustic sealant or by adding additional fiberglass to fill the space completely.

Consider Double Layers or Overlapping: To further minimize the chance of sound leakage, consider using double layers of fiberglass or overlapping the material at joints to ensure a more solid barrier. This can help prevent sound from finding its way through small gaps or seams.

Weatherstripping for Windows and Doors: In areas where windows or doors are a major source of sound leakage, consider using weatherstripping to create a tighter seal. Weatherstripping materials, such as foam tape or rubber seals, can help reduce the gaps around windows and doors, limiting sound transmission.

Don’t Forget Electrical Outlets: In many cases, electrical outlets can be a significant source of sound leakage. Use foam gaskets or putty pads designed for soundproofing to fill the gaps around electrical outlets and switches.

By sealing air gaps thoroughly, you can significantly enhance the soundproofing performance of fiberglass. Minimizing sound leakage points ensures that more sound waves are absorbed by the fiberglass, leading to a more effective reduction in noise transmission.

Take the time to carefully inspect and seal any potential air gaps during the installation process. Proper attention to detail in sealing these gaps will help maximize the benefits of using fiberglass for soundproofing in your space.

Regular Maintenance

Maintaining your fiberglass soundproofing over time is important to ensure its long-term effectiveness. Regular maintenance will help preserve its sound-absorbing properties and prolong its lifespan. Here are some essential tips for maintaining fiberglass soundproofing:

Regular Inspections: Conduct routine inspections of your fiberglass soundproofing to check for any signs of damage, wear, or compression. Inspect the material for tears, gaps, or loose sections that may have developed over time. Identifying and addressing issues early on can prevent further damage and maintain the soundproofing effectiveness.

Repair or Replace Damaged Areas: If you notice any damage or degradation in the fiberglass, such as tears or compression, take action promptly. Repair or replace the affected areas to ensure continuity in the soundproofing barrier. Depending on the extent of the damage, you may need to consult with professionals to determine the best course of action.

Avoid Excessive Moisture: Fiberglass can be susceptible to damage if exposed to excessive moisture or water leaks. Ensure that the surrounding areas are properly waterproofed and sealed to prevent moisture from reaching the fiberglass. If any moisture damage is identified, it is crucial to address it promptly to avoid compromising the soundproofing performance.

Protect from Potential Impact: Take precautions to protect the fiberglass from potential impact or physical damage. Keep the area surrounding the soundproofing clear of objects that could cause damage or compression. Be cautious when moving furniture or equipment near the fiberglass to prevent accidental damage.

Keep the Surrounding Area Clean: Regularly clean the area around the fiberglass soundproofing to prevent the buildup of dust, dirt, or debris. Accumulated debris can affect the sound absorption properties of the fiberglass and potentially compromise its performance. Use a soft brush or vacuum with a brush attachment to gently remove any dust or dirt particles.

Follow Manufacturer’s Guidelines: Adhere to the manufacturer’s guidelines and recommendations for maintenance specific to the type of fiberglass used. Manufacturers often provide specific instructions on cleaning methods, maintenance schedules, and any specialized products that can be used to preserve the fiberglass’s performance and appearance.

Regular maintenance of your fiberglass soundproofing will help ensure its continued effectiveness in reducing noise transmission. By inspecting for damage, making repairs when necessary, protecting from impact, and keeping the area clean, you can maintain the soundproofing performance and extend the lifespan of the fiberglass material.

Additionally, consulting with soundproofing professionals for guidance on maintenance practices specific to your fiberglass product is advisable to ensure proper upkeep and optimal results.

Conclusion

Fiberglass is a versatile and effective solution for soundproofing various spaces. Its ability to absorb and dampen sound waves makes it a popular choice for creating quieter and more peaceful environments. Whether you are soundproofing a residential space, office, studio, or industrial building, fiberglass offers numerous benefits.

We explored the different types of fiberglass used for soundproofing, including batt insulation, blown-in, acoustic panels, and fiberglass wool. Each type has its own unique characteristics and applications, catering to different soundproofing needs. The factors to consider when selecting fiberglass include the Sound Transmission Class (STC) rating, density, installation method, and fire safety.

Fiberglass offers several key benefits for soundproofing. It provides effective noise reduction by absorbing and reducing airborne and impact noise. It also offers thermal insulation properties, helping to regulate temperature and improve energy efficiency. Fiberglass is a cost-effective solution, readily available and easy to install, making it accessible for a wide range of projects. Its versatile application allows for customization to suit various spaces and requirements.

To optimize the performance of fiberglass for soundproofing, proper installation techniques should be followed, including accurate measurement, secure fitting, and sealing of air gaps. Choosing the right thickness of fiberglass, addressing potential sound leakage points, and regular maintenance are essential for long-term effectiveness.

In conclusion, fiberglass provides an excellent soundproofing solution, enhancing the acoustic comfort of any space. Its effectiveness in noise reduction, thermal insulation, cost-effectiveness, and versatile application make it a preferred choice for homeowners, businesses, and soundproofing professionals alike. By harnessing the power of fiberglass, you can create a quieter and more peaceful environment, promoting productivity, relaxation, and well-being.