Home>Instruments>Brass Instruments>What Solder For Brass Instruments

Brass Instruments

What Solder For Brass Instruments

Published: January 15, 2024

Looking for the right solder for brass instruments? Discover the best options and techniques for soldering brass instruments effectively and efficiently.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for AudioLover.com, at no extra cost. Learn more)

Table of Contents

- Introduction

- Understanding Brass Instruments

- Importance of Solder in Brass Instruments

- Types of Solder for Brass Instruments

- Factors to Consider When Choosing Solder for Brass Instruments

- Recommended Solder Options for Brass Instruments

- Proper Soldering Techniques for Brass Instruments

- Maintenance Tips for Brass Instruments

- Common Mistakes to Avoid When Soldering Brass Instruments

- Conclusion

Introduction

When it comes to musical instruments, brass instruments have a unique charm and a rich history that has captivated musicians and audiences alike for centuries. From the powerful sound of a trumpet to the warm tones of a French horn, brass instruments are versatile and dynamic. Behind the scenes, there is a lesser-known component that plays a crucial role in ensuring these instruments perform at their best: solder.

Solder, a metal alloy with a low melting point, is used in the construction and repair of brass instruments. It serves as a binding agent, connecting different parts and joints to create a seamless and airtight instrument. Without proper soldering, brass instruments would be prone to leaks, resulting in diminished sound quality and performance.

In this article, we will explore the importance of solder in brass instruments and discuss the different types of solder available. We will also delve into the factors to consider when choosing solder for brass instruments and offer some recommended solder options. Additionally, we will provide insights into proper soldering techniques and maintenance tips for brass instruments and highlight common mistakes to avoid.

Whether you are a professional musician, a brass instrument enthusiast or a repair technician, understanding the significance of solder and its role in brass instruments is essential. So, let’s dive in and unlock the secrets behind soldering brass instruments to ensure their longevity and optimal performance.

Understanding Brass Instruments

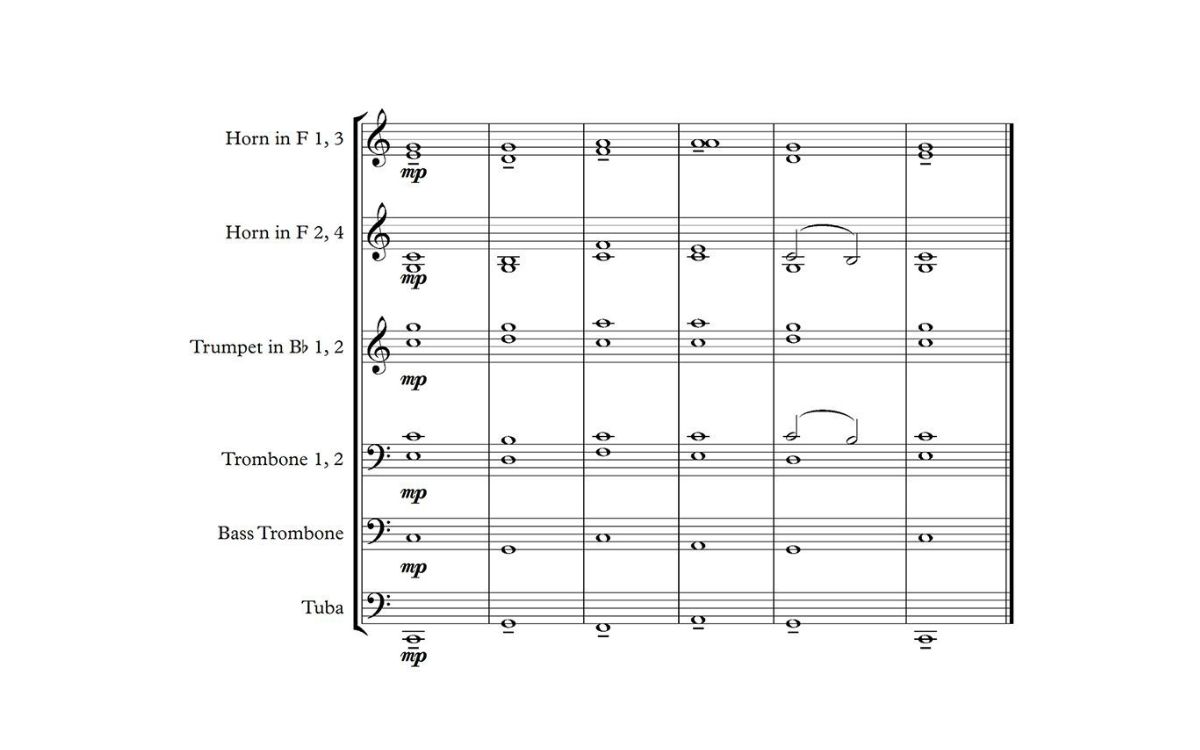

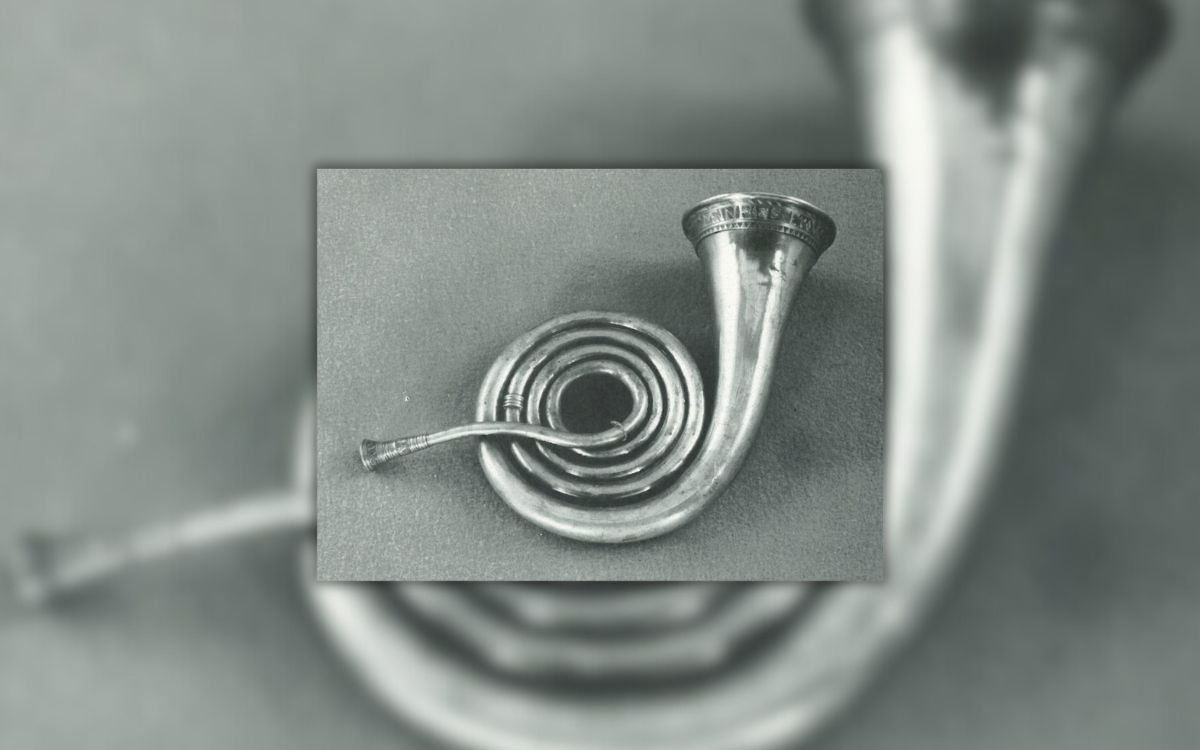

Before delving into the importance of solder in brass instruments, it’s crucial to have a basic understanding of these fascinating musical creations. Brass instruments belong to the brass family of instruments, which also includes trumpets, trombones, tubas, and more.

The defining feature of brass instruments is their construction, which consists of a tubular body made primarily of brass. The sound is produced when the musician vibrates their lips against a cup-shaped mouthpiece, creating a column of air that resonates within the instrument. By manipulating valves or slides, the musician can change the length of the tubing, altering the pitch and producing different notes.

Brass instruments have a long and storied history, with roots dating back to ancient civilizations. Over the centuries, they have evolved in shape, size, and design, resulting in a diverse family of instruments that each possesses its own unique characteristics and playing techniques.

Each instrument within the brass family has its own range, tonal qualities, and playing styles. trumpets are known for their brilliant and piercing sound, while trombones excel in producing smooth and rich tones. French horns, on the other hand, have a softer and warmer sound, making them perfect for orchestral settings. Regardless of their differences, all brass instruments require precise construction and attention to detail to ensure optimal performance.

In the next sections, we will explore the significance of solder in maintaining the structural integrity and functionality of these magnificent brass instruments.

Importance of Solder in Brass Instruments

When it comes to brass instruments, solder plays a vital role in maintaining their structural integrity and ensuring optimal playability. Here are some key reasons why solder is important:

- Creating airtight seals: Brass instruments rely on airtight seals to produce clear and resonant tones. Solder is used to join various components, such as tubing, valves, and slides, to create airtight connections. These connections prevent air leaks, which can result in a loss of sound quality, decreased projection, and difficulty in playing. The precision and quality of soldering are crucial in achieving airtight seals and maintaining the instrument’s performance.

- Securing joints and braces: Brass instruments have numerous joints and braces that hold the instrument’s components together. Solder is used to secure these joints, enhancing the overall stability and durability of the instrument. Properly soldered joints ensure that the instrument can withstand the demands of frequent playing and transportation without compromising its structure.

- Preventing corrosion: Brass instruments are susceptible to corrosion due to exposure to moisture, saliva, and other environmental factors. Solder acts as a protective barrier by covering exposed areas and preventing direct contact with these corrosive elements. This helps to prolong the lifespan of the instrument and maintain its appearance and performance.

- Facilitating repairs and modifications: Over time, brass instruments may require repairs or modifications to address issues such as damaged valves, dents, or worn-out components. Solder enables technicians to effectively and seamlessly repair or replace these parts. It allows for precise and controlled application, ensuring that the repaired areas integrate seamlessly with the existing structure of the instrument.

Without the proper use of solder, brass instruments would be prone to air leaks, structural instability, and accelerated deterioration. Therefore, understanding the importance of solder and its role in maintaining brass instruments is crucial for musicians and technicians who work with these instruments.

Types of Solder for Brass Instruments

When it comes to soldering brass instruments, selecting the right type of solder is essential for achieving reliable and long-lasting results. Here are the main types of solder commonly used for brass instruments:

- Lead-based solder: Historically, lead-based solder was commonly used in the construction and repair of brass instruments. However, due to environmental concerns and health risks associated with lead exposure, its use has become less prevalent. Lead-based solder typically has a lower melting point, making it easier to work with, but its use is now restricted in many countries.

- Lead-free solder: Today, lead-free solders have become the preferred choice for soldering brass instruments. These solders are composed of various alloys, such as tin, silver, and copper, and are designed to offer comparable performance to their lead-based counterparts. Lead-free solder typically has a higher melting point, which can require more skill to work with, but it meets modern safety standards and regulations.

- Silver solder: Silver solder, also known as silver brazing alloy, contains a higher percentage of silver compared to standard solder. It offers superior strength and durability, making it ideal for high-stress areas, such as valve connections and bracings. Silver solder requires higher temperatures to melt and flow properly, requiring the use of a higher temperature torch or soldering iron.

- Flux: In addition to the solder itself, the use of flux is essential when soldering brass instruments. Flux is a chemical compound that helps to remove oxidation and impurities from the surfaces being soldered. It also improves the wetting and flow of the solder, ensuring proper adhesion and bonding. It’s important to choose a flux that is specifically designed for brass to ensure compatibility and optimal soldering results.

When choosing solder for brass instruments, consider factors such as the instrument’s specific requirements, the skill level of the person performing the soldering, and any local regulations regarding the use of lead-based solder. Consulting with a professional technician or instructor can provide valuable guidance in selecting the most suitable solder for the job.

Factors to Consider When Choosing Solder for Brass Instruments

Choosing the right solder for brass instruments is crucial for achieving optimal results in terms of both performance and longevity. Consider the following factors when selecting solder:

- Melting point: The melting point of the solder is an important consideration, as it determines the temperature required for proper soldering. The solder should have a melting point suitable for the specific brass instrument being worked on and the skill level of the person performing the soldering. Lead-free solders typically have higher melting points compared to lead-based solders, so it’s important to choose one that can be successfully melted without damaging the instrument.

- Composition: The composition of the solder is another key factor. Lead-based solders are no longer widely used due to health and environmental concerns, so lead-free solder options have become more popular. These solders often contain alloys such as tin, silver, and copper. Consider the desired strength, durability, and appearance of the solder joint when choosing the solder composition.

- Compatibility: Ensure that the solder you choose is compatible with brass and other materials commonly found in brass instruments. Some solders are specifically formulated for brass, while others may be more versatile and suitable for multiple materials. Using a solder that is designed for brass ensures better adhesion and durability.

- Regulatory compliance: Check local regulations regarding the use of lead-based solder, as its usage is restricted or prohibited in many jurisdictions due to its environmental impact and health risks. Opting for lead-free solder ensures compliance with these regulations and promotes safer soldering practices.

- Skill level: Consider the skill level of the person who will be performing the soldering. Some solders require more expertise and higher temperatures to work effectively, while others are more forgiving and easier to handle. Choosing a solder that aligns with the soldering skills of the individual can help achieve better results.

By considering these factors, you can make an informed decision when choosing solder for brass instruments. It’s always recommended to consult with a professional technician or instructor for guidance in selecting the most appropriate solder for your specific needs.

Recommended Solder Options for Brass Instruments

When it comes to soldering brass instruments, it’s important to choose high-quality solder that is suitable for brass and other materials commonly found in these instruments. Here are some recommended solder options:

- Lead-free silver solder: Lead-free silver solder is a popular choice for soldering brass instruments due to its durability and compatibility. It typically contains a combination of tin, silver, and copper, offering excellent strength and corrosion resistance. This type of solder is suitable for various brass instrument repairs, including valve work and joint soldering.

- Flux-core solder: Flux-core solder is a convenient option that eliminates the need to apply flux separately. It has a flux core within the solder wire, which activates and cleans the surfaces during soldering. This type of solder is often lead-free and suitable for general brass instrument repairs and joint soldering.

- Silver brazing alloy: Silver brazing alloy, also known as silver solder, offers superior strength and durability. It contains a high percentage of silver, which enhances its performance and reliability. Silver brazing alloy is commonly used when soldering high-stress areas of brass instruments, such as valve connections and bracings.

- Brass-specific solders: Some solder manufacturers offer solder specifically formulated for brass instruments. These solders are designed to provide excellent adhesion and durability when used on brass surfaces. They often have lower melting points to prevent damage to the brass during soldering.

When selecting solder for your brass instrument, consider the specific repair or soldering task at hand. It’s also important to follow manufacturer guidelines and consult with a professional technician or instructor for their expertise and recommendations. Proper solder selection ensures reliable and long-lasting repairs while preserving the integrity of the instrument.

Proper Soldering Techniques for Brass Instruments

Proper soldering techniques are crucial when working with brass instruments to ensure successful and durable repairs. Here are some essential soldering techniques to keep in mind:

- Clean and prepare the surfaces: Before soldering, it’s important to thoroughly clean and prepare the surfaces to be soldered. Remove any dirt, debris, or oxidation using brass cleaning solvents or abrasive pads. This ensures better adhesion and a stronger bond between the solder and the brass. Apply a brass-specific flux to the surfaces for improved wetting and flow of the solder.

- Heat control: Proper heat control is vital during soldering. Use a soldering iron or torch with adjustable temperature settings to avoid overheating the brass, which can lead to discoloration, warping, or distortion. Heat the joint evenly and gradually to allow the solder to flow smoothly and ensure a strong bond.

- Apply solder strategically: Apply the solder carefully and strategically to the joint. Touch the solder to the joint, not the heat source, to allow it to melt and flow onto the prepared surfaces. Move the solder around the joint, evenly distributing it for a uniform and solid connection. Avoid excessive soldering, as it can create messy and weak joints.

- Use soldering aids: When working with complex joints or hard-to-reach areas, consider using soldering aids such as clips, clamps, or third hands to hold the components securely in place during soldering. This helps maintain proper alignment and stability, ensuring a neat and precise solder joint.

- Clean and inspect the solder joint: Once the soldering is complete, allow the joint to cool naturally. Avoid using excessive air or water to cool it quickly, as it can cause thermal shock and affect the integrity of the solder. After cooling, clean the solder joint to remove any flux residue or excess solder. Inspect the joint for any imperfections or irregularities and make any necessary touch-ups or adjustments.

Remember to practice proper safety precautions during soldering, such as wearing heat-resistant gloves and eye protection. If you are new to soldering or unsure about the process, it’s always recommended to seek guidance from a professional technician or instructor to ensure the best results and prevent any damage to your brass instrument.

Maintenance Tips for Brass Instruments

Maintaining brass instruments is vital for their longevity, performance, and overall sound quality. Here are some essential maintenance tips to keep your brass instrument in optimal condition:

- Regular cleaning: Clean your brass instrument regularly to remove dirt, oils, and debris. Use a brass instrument-specific cleaning solution and a soft cloth or brush to gently clean the exterior surfaces. Pay special attention to areas where moisture accumulates, such as the mouthpiece and valve casings.

- Valve maintenance: Regularly inspect and lubricate the valves of your brass instrument. Remove the valves and clean them with a mild detergent and warm water. Apply a small amount of valve oil to ensure smooth and efficient valve action. Avoid using excessive oil, as it can attract dirt and impede the valve’s movement.

- Slide care: Clean and lubricate the slides of the brass instrument. Remove the slides carefully, clean them with a slide cleaning solution or warm soapy water, and dry them thoroughly before applying a slide grease or oil. Make sure the slides move smoothly without sticking or excessive resistance.

- Storage: Store your brass instrument in a suitable case to protect it from dust, moisture, and other elements. Keep the instrument in an upright position and avoid placing heavy objects on top of it. Additionally, consider using moisture control products such as desiccant packs or moisture-trapping materials inside the case to prevent excess humidity buildup.

- Proper handling: Handle your brass instrument with care to avoid accidental damage. Keep your hands clean and dry before playing to prevent sweat and oils from corroding the brass. When assembling or disassembling the instrument, hold it by the sturdier parts, such as the valve casing or slide barrel, to avoid bending or denting more delicate components.

- Professional maintenance: Regularly take your brass instrument to a professional technician for maintenance and servicing. They can perform thorough cleanings, inspect for any damage or loose parts, and make necessary repairs or adjustments. Professional maintenance ensures the instrument remains in top playing condition and can help prevent any serious issues from developing.

By following these maintenance tips, you can prolong the lifespan of your brass instrument and enjoy consistent performance and sound quality for years to come. Remember to consult your instrument’s specific manufacturer recommendations and reach out to a professional technician for any specific concerns or questions you may have.

Common Mistakes to Avoid When Soldering Brass Instruments

Soldering brass instruments requires precision, attention to detail, and proper technique. To ensure successful repairs and avoid potential damage, here are some common mistakes to avoid when soldering brass instruments:

- Overheating: Overheating the brass can cause discoloration, warping, or distortion. Avoid applying excessive heat or leaving the heat source in one spot for too long. Use a soldering iron or torch with adjustable temperature settings and work with patience and control to prevent overheating.

- Insufficient cleaning: Failing to properly clean and prepare the surfaces before soldering can result in poor adhesion and weak joints. Take the time to thoroughly clean the surfaces, removing any dirt, debris, or oxidation, and apply a brass-specific flux to ensure optimal solder flow and bonding.

- Using improper solder: Using the wrong type of solder or flux can lead to subpar results. Ensure that the solder you choose is specifically designed for brass instruments and that the flux is compatible. Using the correct solder and flux ensures better adhesion, durability, and longevity of the solder joint.

- Excessive soldering: Applying too much solder can create messy and weak joints. Use only the necessary amount of solder to achieve a strong and neat joint. Excessive solder can also lead to excess buildup, affecting the instrument’s playability and hindering future repairs or modifications.

- Poor heat distribution: Uneven heat distribution can result in incomplete solder flow and weak joints. Ensure that the heat is evenly applied to the joint, allowing the solder to melt and flow smoothly. Move the heat source around the joint, maintaining an even distribution for consistent results.

- Insufficient safety precautions: Soldering requires the use of heat, flux, and potentially hazardous materials. Take proper safety precautions by wearing heat-resistant gloves, protective eyewear, and working in a well-ventilated area. Avoid touching the heated surfaces, as they can cause severe burns.

- Ignoring professional guidance: If you are new to soldering or face a complex repair, seeking professional guidance is highly recommended. Ignoring or dismissing professional advice can lead to costly mistakes and potential damage to your brass instrument. Consult with a professional technician or instructor for guidance, especially for intricate repairs or modifications.

By avoiding these common mistakes and practicing proper soldering techniques, you can ensure successful brass instrument repairs and maintain the instrument’s integrity and performance. If you are uncertain or lack experience in soldering, consider seeking professional assistance to ensure the best results.

Conclusion

The art of soldering is an essential skill in the world of brass instruments. Selecting the right solder, understanding proper techniques, and adhering to maintenance practices are crucial for maintaining the structural integrity, playability, and longevity of brass instruments.

Solder plays a vital role in creating airtight seals, securing joints, preventing corrosion, and facilitating repairs and modifications in brass instruments. Choosing the appropriate solder, whether it is lead-free, silver solder, or brass-specific solder, is essential for achieving reliable and long-lasting results. Furthermore, understanding the factors to consider when choosing solder, including melting point and composition, is crucial to ensure compatibility and compliance with regulations.

To achieve successful soldering, proper techniques are essential. Cleaning and preparing surfaces, controlling heat, strategic solder application, and using soldering aids are fundamental steps to create strong and neat joints. Following safety precautions and seeking professional guidance when necessary is paramount to avoid common mistakes and potential damage.

Maintaining brass instruments through regular cleaning, valve and slide care, proper handling, and professional maintenance ensures their optimal performance and longevity. Adhering to these maintenance practices helps to prevent issues such as damage caused by dirt, moisture, and mishandling.

In conclusion, soldering is an integral part of maintaining and repairing brass instruments. By understanding the importance of solder, selecting the right type, and mastering proper soldering techniques, musicians and technicians can ensure the best results. By providing regular care and maintenance, brass instrument owners can enjoy the full potential of their instruments and keep them playing beautifully for years to come.