Home>Devices & Equipment>Turntable>How To Make A Turntable For 3D Model

Turntable

How To Make A Turntable For 3D Model

Published: January 19, 2024

Learn how to make a turntable for your 3D model with our easy step-by-step guide. Create smooth and professional rotations with our turntable tutorial.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for AudioLover.com, at no extra cost. Learn more)

Table of Contents

Introduction

Are you a fan of vinyl records and looking to add some nostalgia to your music listening experience? Building your own turntable can be a rewarding and fulfilling project. Not only will you have a unique piece of equipment, but you’ll also have the satisfaction of knowing that you put it together yourself.

In this article, we will guide you through the process of building a turntable for a 3D model. We’ll cover the materials needed, step-by-step instructions, and provide helpful tips along the way. So if you’re ready to embark on a DIY audio adventure, let’s get started!

Before we dive into the details, it’s important to note that building a turntable requires some technical knowledge and basic DIY skills. If you’re not comfortable working with electronic components or troubleshooting, it might be best to consult an expert or consider purchasing a ready-made turntable. However, if you’re up for the challenge and eager to learn, building your own turntable can be a rewarding experience.

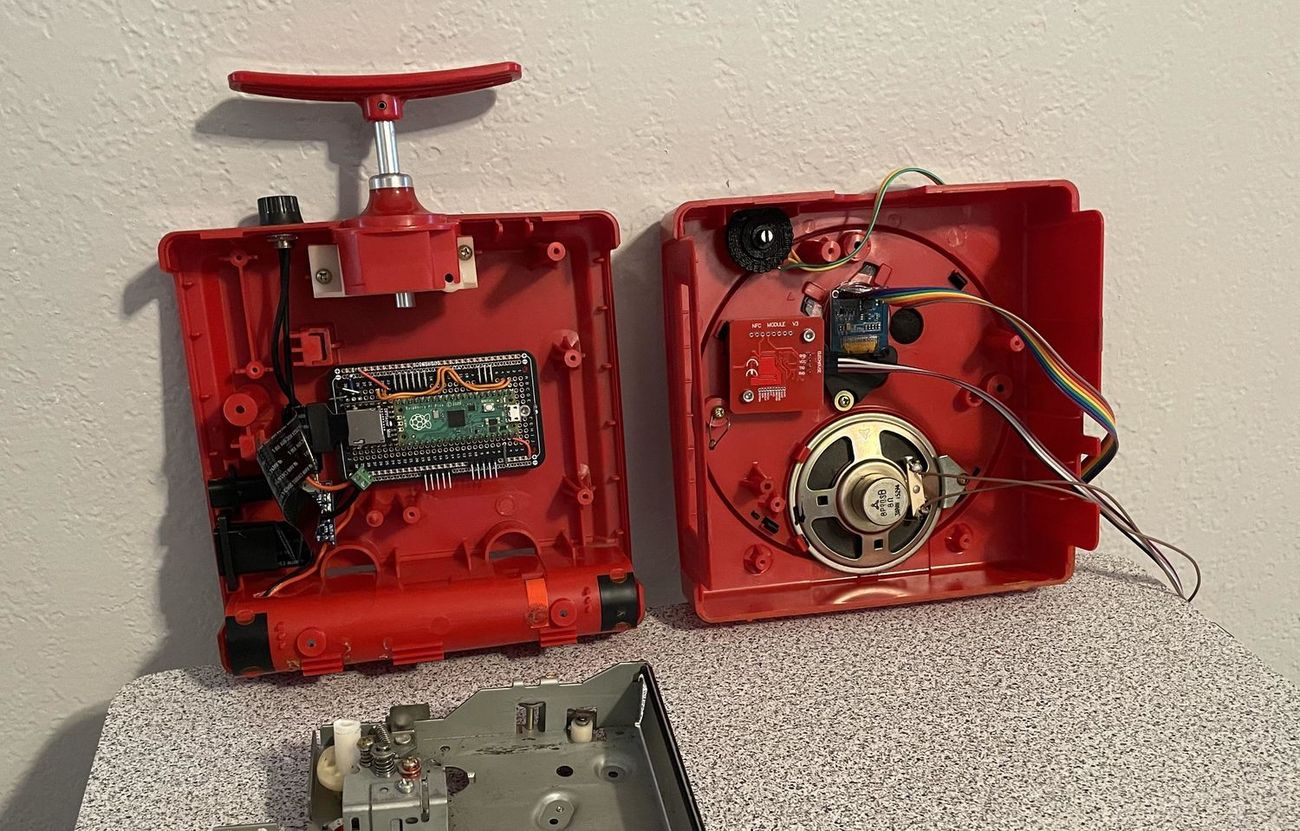

So, what exactly is a turntable? A turntable, also known as a record player or phonograph, is a device used to play vinyl records. It consists of several components, including a motor, a platter or platform where the record sits, and a tonearm with a stylus or needle that tracks the grooves of the record to produce sound.

By building your own turntable, you have the freedom to customize and personalize the design, choose the specific components, and even experiment with different setups and modifications. Whether you’re a seasoned audiophile or simply enjoy the warm sound of vinyl, creating your own turntable can add a unique touch to your music listening experience.

Materials needed

To build your own turntable for a 3D model, you will need to gather the following materials:

- A 3D model of the turntable: This will serve as the blueprint for your build. You can find ready-made 3D models online or create your own if you have the necessary design skills.

- A motor: The motor is responsible for spinning the turntable’s platter. Look for a motor with sufficient torque and speed to ensure smooth rotation.

- A platter: The platter is where you will place the vinyl record. It should be sturdy and balanced to minimize vibrations and provide stable playback.

- A tonearm: The tonearm holds the stylus or needle that tracks the grooves of the record. It should be adjustable to accommodate different cartridge weights and tracking forces.

- A cartridge: The cartridge contains the stylus and converts the mechanical vibrations from the grooves into electrical signals. Choose a high-quality cartridge for optimal sound reproduction.

- A stylus: The stylus is the needle that makes contact with the record’s grooves. It should be compatible with your chosen cartridge and provide accurate tracking.

- An amplifier: The amplifier amplifies the electrical signals from the cartridge and sends them to the speakers. Make sure your amplifier has a built-in phono stage or obtain a separate phono preamp if needed.

- Speakers: Choose speakers that match the output of your amplifier and provide a clear and balanced sound.

- Cables and connectors: You will need various cables and connectors to connect the components together. Ensure they are of good quality to minimize signal loss and interference.

- Tools: Some essential tools for the build include screwdrivers, pliers, wire cutters, soldering iron, and a multimeter for testing electrical connections.

Additionally, you may want to consider adding optional features such as speed control, anti-vibration measures, and isolation feet to enhance the performance and stability of your turntable.

Before starting the build, it’s important to have all the necessary materials and tools ready. This will ensure a smooth and efficient assembly process. Now that you have your materials list, let’s move on to the next step: assembling the turntable base.

Step 1: Gathering the necessary components

Before you start assembling your turntable, it’s important to gather all the necessary components. Having everything you need at hand will make the process much smoother. Here’s a breakdown of the essential components:

- Turntable base: This is the foundation of your turntable. It can be made of wood, acrylic, or other materials of your choice. Make sure it is sturdy and provides stability for the rest of the components.

- Motor: Look for a high-quality, low-noise motor with suitable specifications for your turntable. The motor should provide consistent speed and smooth rotation for accurate playback.

- Platter: The platter is the rotating disc that holds the vinyl record. It should have enough weight to provide stability and minimize vibrations. Choose a platter material that reduces resonance and allows for easy record changes.

- Tonearm: The tonearm holds the stylus and allows it to track the record’s grooves. It should be adjustable for different cartridge weights and provide smooth and precise movement. Look for a tonearm that offers anti-skate adjustment for optimal tracking.

- Cartridge and stylus: The cartridge contains the stylus or needle that reads the record’s grooves and converts the vibrations into electrical signals. Choose a high-quality cartridge that matches your listening preferences and budget. Make sure the stylus is compatible with the cartridge and provides accurate tracking.

- Phono preamp: If your amplifier doesn’t have a built-in phono stage, you’ll need a separate phono preamp to amplify the signal from the cartridge and equalize it. Look for a preamp that matches the output of your cartridge.

- Wiring and cables: You’ll need various cables to connect the components together, including RCA cables for connecting the turntable to the phono preamp or amplifier, and grounding cables to reduce noise and hum. Use high-quality cables to ensure optimal signal transfer.

- Power supply: Depending on the motor you choose, you’ll need a suitable power supply to provide the necessary voltage and current. Check the motor’s specifications to determine the correct power supply requirements.

- Tools: You’ll need a set of tools for the assembly process, including screwdrivers, pliers, wire cutters, and soldering equipment. These tools will help you connect the components, secure them to the turntable base, and make any necessary adjustments.

Once you have gathered all the necessary components and tools, you’re ready to move on to the next step: assembling the turntable base.

Step 2: Assembling the turntable base

Now that you have all the necessary components, it’s time to start assembling your turntable. The first step is to build the turntable base, which will provide a stable platform for the motor, platter, and tonearm. Here’s a step-by-step guide:

- Prepare the base: Begin by preparing the base of your turntable. This can be a wooden board, an acrylic platform, or any other sturdy material of your choice. Make sure the base is large enough to accommodate all the components and has enough space for any future modifications or upgrades.

- Mount the motor: Determine the ideal location for the motor on the turntable base. The motor should be positioned in a way that allows easy access to the platter and tonearm. Secure the motor to the base using screws or mounting brackets, ensuring it is firm and stable.

- Attach the platter: Place the platter on the motor spindle, aligning it properly. Some platters may require a separate adapter to fit onto the motor spindle. Follow the manufacturer’s instructions for proper installation. Ensure that the platter sits smoothly on the spindle and rotates freely without any obstructions.

- Install the tonearm: Position the tonearm mount on the turntable base. Attach the tonearm to the mount, following the manufacturer’s instructions. Make sure the tonearm pivot point is aligned with the center of the platter and the tonearm moves smoothly across the surface. Adjust any necessary counterweights or anti-skate settings as specified by the tonearm manufacturer.

- Secure the wiring: Organize and secure the wiring of the motor, tonearm, and any other components to prevent them from interfering with the turntable’s operation. Use cable ties or adhesive clips to neatly route the wires along the base, ensuring they don’t obstruct the movement of the platter or tonearm.

- Check for stability: Once all the components are in place, double-check the stability of the turntable base. Give it a gentle shake to ensure there are no loose connections or wobbly parts. If necessary, make any adjustments or tighten any screws to ensure a secure and stable setup.

Remember to refer to the instruction manuals provided with your specific components for any additional guidelines or specifications. Each turntable build may have slight variations depending on the chosen components and design. With the turntable base assembled, you’re ready to move on to the next step: wiring the motor.

Step 3: Wiring the motor

Now that you have assembled the turntable base, it’s time to wire the motor. The motor is a crucial component that provides the power to rotate the platter, allowing your vinyl records to play smoothly. Here’s a step-by-step guide on how to wire the motor:

- Identify the motor wires: Most motors have multiple wires, typically color-coded. Refer to the motor’s instruction manual or specifications to identify the different wires. The common wire colors you may encounter include red, black, blue, and yellow.

- Identify the power supply requirements: Check the motor’s specifications to determine the voltage and current requirements. This information will help you select the appropriate power supply for the motor.

- Connect the power supply: Connect the appropriate wires from the power supply to the motor. Typically, you will connect the positive (+) wire from the power supply to the motor’s positive (+) wire and the negative (-) wire to the motor’s negative (-) wire.

- Secure the connections: Once the wires are connected, ensure that the connections are secure and stable. Use wire connectors or solder the wires together, depending on the type of motor and wiring method suggested by the manufacturer.

- Test the motor: Before proceeding further, it’s important to test the motor to ensure it is functioning correctly. Connect the motor to the power supply and observe its rotation. Verify that the platter spins smoothly and at the desired speed. If you notice any issues, double-check the wiring and consult the motor’s manual for troubleshooting steps.

- Route the motor wiring: After confirming the motor’s functionality, route the motor wiring along the turntable base. Use cable ties or adhesive clips to secure the wiring in place and prevent any interference with the platter or tonearm movement.

Remember to handle the wiring with care and ensure that the connections are safe and reliable. If you are unsure about any aspect of the motor wiring or lack experience with electrical components, seek assistance from someone with expertise in this area. Once the motor is successfully wired, you can proceed to the next step: mounting the turntable platform.

Step 4: Mounting the turntable platform

With the motor wired and functioning properly, it’s time to mount the turntable platform onto the base. The turntable platform, also known as the plinth, provides a solid surface for the platter, tonearm, and other components. Here’s a step-by-step guide on how to mount the turntable platform:

- Prepare the turntable platform: Ensure that the turntable platform is clean and free of any debris. If necessary, sand or polish the surface to achieve a smooth finish.

- Measure and mark the placement: Determine the ideal placement for the turntable platform on the base. Consider factors such as accessibility to the tonearm and aesthetic preferences. Use a pencil or marker to mark the desired position.

- Attach the platform to the base: Depending on your chosen method, you may use screws, adhesive, or other fasteners to attach the turntable platform to the base. Follow the manufacturer’s instructions or your design plan to ensure a secure and stable attachment. Take care not to damage any internal components during this process.

- Check for alignment: Once the turntable platform is attached, double-check that it is aligned properly with the motor and other components. Ensuring the platform is level and parallel with the base will help maintain consistent playback performance.

- Secure any additional components: If you have additional components such as isolation feet, vibration-damping materials, or speed control mechanisms, mount them onto the turntable platform as instructed by the manufacturer. These components can enhance the performance and stability of your turntable.

- Test the stability: Give the turntable platform a gentle shake to ensure it is securely mounted. Verify that all components are firmly in place and there is no excessive movement or wobbling. Make any necessary adjustments or tighten any screws to ensure a stable and solid structure.

Take your time during this step to ensure that the turntable platform is mounted correctly. A securely attached turntable platform will not only provide a stable and reliable playback experience but also contribute to the overall aesthetics of your homemade turntable. Once the turntable platform is properly mounted, you’re ready to move on to the next step: connecting the turntable to a power source.

Step 5: Connecting to a power source

Now that your turntable is assembled and the platform is securely mounted, it’s time to connect it to a power source. The power source provides the necessary electrical current to drive the motor and other components. Here’s a step-by-step guide on how to connect your turntable to a power source:

- Check the motor’s power requirements: Refer to the motor’s specifications or instruction manual to determine the voltage and current requirements. This information will help you select the appropriate power source.

- Choose a suitable power supply: Based on the motor’s power requirements, select a power supply that matches the voltage and current specifications. You can choose a wall adapter, power brick, or any other suitable power source that can deliver the required power.

- Connect the power source: Depending on the type of power source chosen, you may need to connect it to the motor using the appropriate cables or connectors. Ensure that the polarity is correct, with positive (+) and negative (-) terminals aligned properly.

- Verify the connection: Once the power source is connected, double-check the wiring to ensure there are no loose connections or exposed wires. Make sure that the power source is securely connected to the motor and there are no signs of damage or frayed cables.

- Plug in the power source: Plug the power source into a suitable electrical outlet. Ensure that the outlet is grounded and can handle the power requirements of your turntable. Avoid using power outlets that are already heavily loaded or sharing the same circuit with other high-power devices to minimize potential interference or voltage fluctuations.

- Test the power connection: Turn on the power source and observe the motor’s operation. The platter should start rotating smoothly and at the desired speed. If there are any issues, double-check the power connections and consult the motor’s manual for troubleshooting steps.

It’s essential to ensure the safety and stability of the power connections. Double-check all connections and ensure they are secure and error-free. If you have any concerns or doubts, consult an expert or an electrician for assistance. With the turntable connected to a power source, you’re now ready to move on to the next step: testing the turntable.

Step 6: Testing the turntable

After completing the assembly and connecting the turntable to a power source, it’s time to test your creation. Testing the turntable will ensure that all the components are functioning correctly and that you can enjoy high-quality vinyl playback. Here’s a step-by-step guide on how to test your turntable:

- Prepare a test record: Select a test record or a vinyl album with which you are familiar. Using a test record can help assess the performance and audio quality of your turntable.

- Place the test record on the platter: Carefully place the test record on the turntable’s platter, ensuring it is centered and properly aligned with the tonearm.

- Balance the tonearm: Use the tonearm’s adjustable counterweight and anti-skate controls to balance the tonearm properly. Adjust the tracking force and anti-skate settings according to the manufacturer’s recommendations or the stylus manufacturer’s specifications.

- Lower the tonearm: Gently lower the tonearm onto the test record, being careful not to apply too much pressure. The stylus should make contact with the record’s grooves and begin playing the audio.

- Listen for audio: As the record plays, listen for any distortions, imbalances, or skipping. Pay attention to the overall sound quality, clarity, and channel separation.

- Check for speed accuracy: Use a turntable speed measurement tool or a smartphone app to check if the platter is rotating at the correct speed. Some turntables have built-in speed control mechanisms that allow you to adjust the rotation speed if necessary.

- Inspect for any issues: While the turntable is playing, visually inspect the tonearm, stylus, and cartridge for any unusual movements, misalignments, or visible damages. These issues may affect the playback quality and performance of the turntable.

Pay close attention to the audio quality, tracking performance, and overall stability of the turntable during the testing phase. Note any observations or issues that arise and make any necessary adjustments or improvements to enhance the performance of your turntable.

Remember, if you encounter any difficulties or notice any persistent issues, consult the instruction manuals of your components, seek advice from experts, or consider reaching out to professional turntable technicians for assistance.

Congratulations on building your own turntable! With successful testing, you can now enjoy the experience of playing your favorite vinyl records with pride and satisfaction.

Conclusion

Building your own turntable for a 3D model can be a gratifying and rewarding project for any music lover or DIY enthusiast. From gathering the necessary components to assembling and testing the final product, you’ve embarked on a journey that combines technical skills and personal creativity. By following the steps outlined in this guide, you’ve learned how to assemble the turntable base, wire the motor, mount the turntable platform, connect to a power source, and test the turntable’s performance.

As you’ve built your turntable, you’ve gained a deeper understanding of its inner workings and the components that contribute to its sound reproduction. Your homemade turntable offers a sense of pride and uniqueness, as you’ve chosen and personalized every aspect of the build. In addition to enjoying the warm analog sound of vinyl records, you’ll also have the opportunity to experiment with modifications and adjustments to further enhance your listening experience.

Remember, building a turntable requires technical knowledge, attention to detail, and patience. If you encounter any challenges along the way, do not hesitate to consult the instruction manuals, seek advice from experts, or consider reaching out to professional turntable technicians for guidance. With proper care and maintenance, your custom-built turntable can provide you with years of joy and nostalgia.

Whether you’re a seasoned audiophile or a hobbyist looking to explore the world of vinyl, building your own turntable is an exciting endeavor. The satisfaction of playing your favorite records on a turntable you’ve built yourself is truly unparalleled. So, pick up your tools, start gathering the components, and enjoy the process of creating a unique, personalized turntable that will bring music to life in an extraordinary way.