Home>Production & Technology>Soundproofing>How Thick Of Soundproofing To Get.

Soundproofing

How Thick Of Soundproofing To Get.

Published: January 26, 2024

"Discover the ideal thickness of soundproofing materials to effectively block unwanted noise. Enhance your acoustic insulation with soundproofing solutions."

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for AudioLover.com, at no extra cost. Learn more)

Table of Contents

Introduction

When it comes to creating a peaceful and quiet environment, soundproofing is the key. Whether you live in an apartment building with noisy neighbors, work in a busy office with constant distractions, or simply want to reduce the impact of external noise on your daily life, soundproofing can make a significant difference. By effectively blocking or absorbing sound waves, soundproofing materials and techniques can help create a more serene and enjoyable space.

In this article, we will explore the importance of soundproofing, factors to consider when choosing the right thickness for your soundproofing needs, common materials used for soundproofing, cost considerations, and installation tips to help you get started on your soundproofing journey.

Not only does soundproofing create a more peaceful atmosphere, but it also offers numerous benefits. By reducing noise pollution, soundproofing can improve concentration, productivity, and overall quality of life. Whether you are trying to create a quiet workspace, enjoy a peaceful night’s sleep, or block out the construction noise from outside, soundproofing can provide the solution you are looking for.

It is important to note that not all soundproofing is created equal. The thickness of the soundproofing materials plays a significant role in their effectiveness. The right thickness will depend on various factors, such as the type and intensity of the noise, the structure of the space, and the desired level of sound reduction.

Before diving into the specifics of thickness recommendations, let’s explore the various factors that should be considered when choosing soundproofing materials.

Importance of Soundproofing

Soundproofing is not just a luxury; it is a necessity in today’s noisy world. Excessive noise can have a significant impact on our well-being, causing stress, fatigue, and even health issues. By implementing soundproofing measures, we can create a peaceful and comfortable environment where we can relax, concentrate, and enjoy uninterrupted sleep.

One of the primary benefits of soundproofing is noise reduction. Whether it is traffic noise, barking dogs, or the hum of appliances, unwanted sound can be incredibly disruptive. Soundproofing materials absorb, block, or dampen sound waves, preventing them from penetrating into our living or working spaces. This isolation of sound ensures that we can focus on our tasks, have restful nights, and maintain a sense of tranquility, even in the midst of a noisy environment.

Aside from the immediate impact on our peace of mind, soundproofing can also improve our productivity and overall quality of life. In a noisy office setting, for example, soundproofing can create a more conducive atmosphere for concentration and collaboration. Similarly, in residential areas, soundproofing can enhance privacy and minimize disturbances from neighboring properties.

Furthermore, soundproofing can offer health benefits. Prolonged exposure to excessive noise levels can lead to stress, anxiety, and even hearing damage. By reducing noise pollution through effective soundproofing, we can safeguard our physical and mental well-being.

Another often overlooked benefit of soundproofing is increased energy efficiency. Soundproofing materials can also act as thermal insulation, preventing the transfer of heat or cold. This can help maintain a comfortable temperature inside our spaces while reducing the load on heating or cooling systems. As a result, soundproofing can contribute to energy savings and lower utility bills.

Overall, soundproofing is a valuable investment that can significantly improve our living and working environments. Whether in residential, commercial, or industrial settings, the importance of soundproofing should not be underestimated. Now that we understand the significance of soundproofing, let’s explore the various factors to consider when choosing the right thickness for your soundproofing needs.

Factors to Consider

When it comes to choosing the right thickness for your soundproofing materials, there are several factors to consider. These factors will help determine the level of sound reduction you desire and the effectiveness of the soundproofing solution in your specific situation.

1. Noise Type and Intensity: The first factor to consider is the type of noise you are trying to reduce and its intensity. Different types of noise have different frequencies and wavelengths, which can be better addressed with specific soundproofing materials. For example, low-frequency noises like heavy machinery may require thicker materials compared to high-frequency noises like voices or music. Understanding the source and characteristics of the noise will help guide you in choosing the appropriate thickness.

2. Desired Level of Sound Reduction: Consider how much sound reduction you are aiming for. Are you looking for a complete soundproofing solution, or do you simply want to reduce the noise to a more tolerable level? The level of soundproofing required will impact the thickness of the materials needed. For example, if you live in an apartment building with loud neighbors, you may need thicker materials to block out the sound completely.

3. Structure of the Space: The structure and layout of the room or space you want to soundproof also play a role in determining the thickness of the materials. For example, if you are soundproofing walls, the thickness of the drywall, insulation, and additional soundproofing layers will affect the overall effectiveness. In the case of windows or doors, you may need to consider specialized soundproofing solutions or thicker materials to address potential weak points.

4. Available Space: Consider the space available for soundproofing. Thicker soundproofing materials may require more space, which can be a limitation in smaller rooms or spaces with restricted dimensions. Ensure that you have enough room to install the desired thickness without compromising functionality or aesthetics.

5. Budget: Soundproofing materials come in various price ranges, with thicker options often being more expensive. Consider your budget and weigh the cost-effectiveness of different thickness options. Keep in mind that investing in higher-quality and thicker materials can provide better long-term soundproofing results.

By taking these factors into account, you can make an informed decision about the appropriate thickness for your soundproofing needs. In the next section, we will explore some recommendations for soundproofing material thickness based on common applications.

Thickness Recommendations

When it comes to determining the right thickness for your soundproofing materials, there is no one-size-fits-all answer. The ideal thickness will depend on various factors, such as the type of noise, the structure of the space, and the desired level of sound reduction. However, here are some general thickness recommendations for common soundproofing applications:

- Walls: For soundproofing walls, a thickness of at least 2 inches (5 cm) is recommended. This can be achieved by using multiple layers of sound-dampening drywall, coupled with insulation materials such as mineral wool or acoustic foam.

- Floors and Ceilings: Similar to walls, for soundproofing floors and ceilings, a thickness of 2 inches (5 cm) or more is recommended. This can be achieved by using multiple layers of sound-dampening materials, such as mass-loaded vinyl or resilient underlayment, along with a thick layer of carpet or acoustic tiles.

- Windows: To soundproof windows, a thickness of at least 1 inch (2.5 cm) is recommended. This can be achieved by using double or triple-pane windows with air or gas-filled chambers between the layers. Additionally, installing thick curtains or using window inserts made of sound-absorbing materials can further enhance sound reduction.

- Doors: For soundproofing doors, a thickness of at least 1.5 inches (3.8 cm) is recommended. Solid-core doors or composite doors are preferred, as they offer better sound insulation compared to hollow-core doors. Adding weatherstripping seals around the door frame can also help minimize sound leakage.

- Air Vents and Ducts: To reduce noise transmission through air vents and ducts, acoustic duct lining or flexible acoustic ducting can be used. The thickness will depend on the size and material of the ducts, but typically a thickness of 1 inch (2.5 cm) or more is recommended to achieve effective soundproofing.

Keep in mind that these thickness recommendations are general guidelines, and the specific requirements for your space may vary. It is always recommended to consult with a soundproofing professional to assess your needs and provide tailored recommendations for your unique situation.

Next, let’s explore some common soundproofing materials that can be used to achieve the desired thickness and sound reduction.

Common Soundproofing Materials

When it comes to soundproofing, there are a variety of materials available that can effectively reduce noise transmission. Here are some common soundproofing materials that can be used to achieve the desired thickness and sound reduction:

- Mass-Loaded Vinyl (MLV): Mass-loaded vinyl is a dense and flexible material that can effectively block sound transmission. It is commonly used as an additional layer in walls, floors, and ceilings. MLV is available in different thicknesses and can be easily installed by attaching it to existing surfaces using adhesive or fasteners.

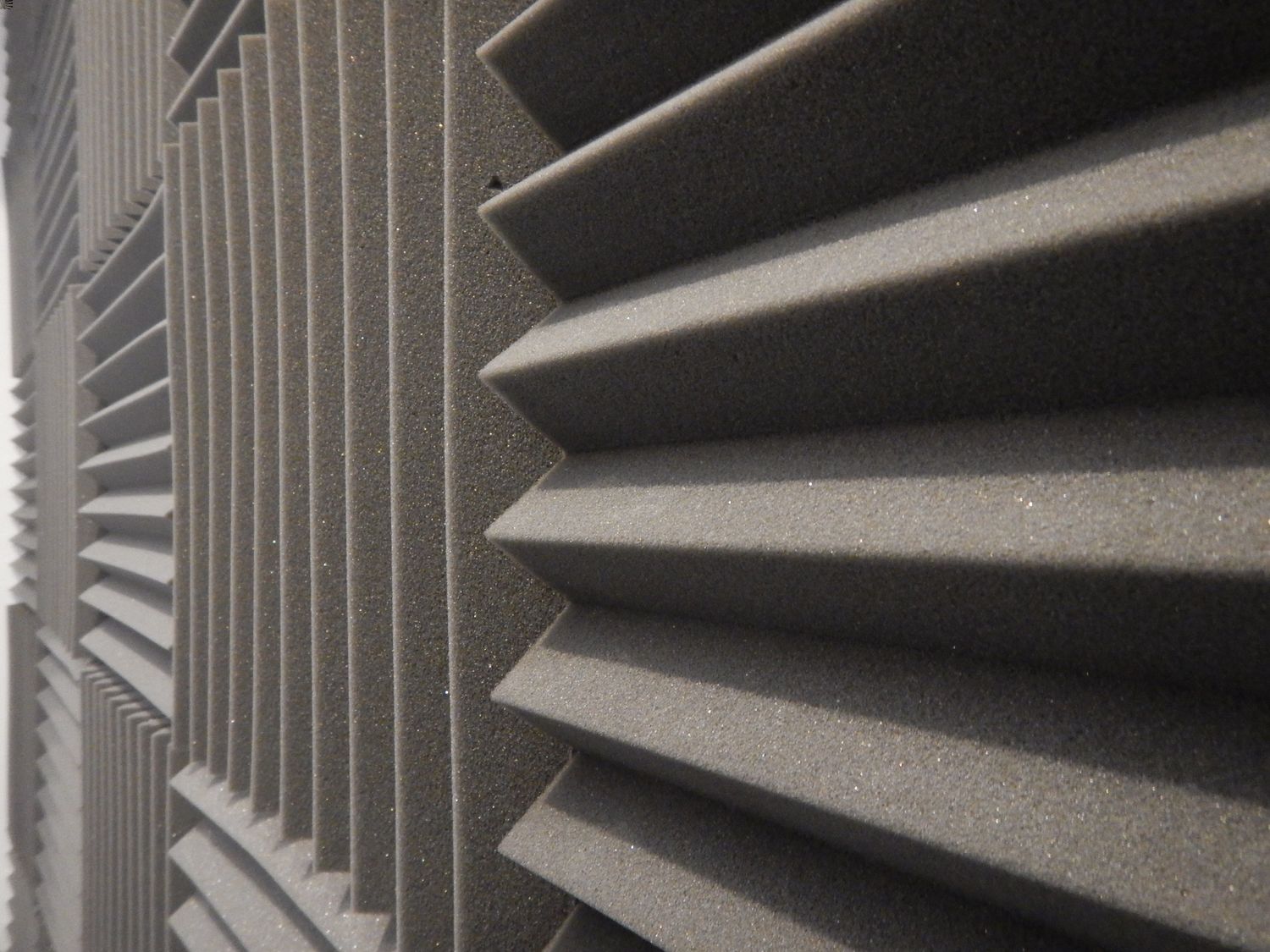

- Absorptive Panels: Absorptive panels, such as acoustic foam or fiberglass panels, are designed to absorb sound waves, reducing echo and reverberation. These panels are available in various thicknesses and can be mounted on walls, ceilings, or even used as room dividers.

- Insulation Materials: Insulation materials, such as mineral wool or cellulose, can provide both thermal and sound insulation. These materials can be installed between wall studs, in ceilings, or within floors to reduce sound transmission. The thickness of the insulation will depend on the desired level of sound reduction.

- Resilient Channels: Resilient channels are thin metal strips that are attached to the framing studs before the installation of drywall. They help decouple the drywall from the structure, reducing the transfer of sound vibrations. By using resilient channels, a thicker layer of drywall can be installed, further enhancing soundproofing.

- Double or Triple-Pane Windows: Upgrading to double or triple-pane windows can significantly reduce noise transmission through windows. The air or gas-filled chambers between the glass layers act as insulation, effectively blocking out external noise. Additionally, using laminated glass can provide an added layer of sound reduction.

These are just a few examples of commonly used soundproofing materials. Depending on your specific needs and budget, there are many other options available in the market. It is important to carefully research and choose materials that are suitable for your noise reduction goals and adhere to your desired thickness requirements.

Now that we have discussed the common soundproofing materials, let’s move on to the cost considerations associated with soundproofing projects.

Cost Considerations

When planning a soundproofing project, it is important to take into account the cost of materials and installation. The total cost will depend on various factors, including the size of the space, the type of soundproofing materials chosen, and whether you plan to do the installation yourself or hire professionals. Here are some cost considerations to keep in mind:

1. Material Costs: The cost of soundproofing materials can vary widely based on the type, thickness, and quality. Mass-loaded vinyl, for example, can range from $1 to $3 per square foot, while acoustic foam panels can vary from $20 to $100 per panel. Research and compare prices from different suppliers or retailers to ensure you are getting the best value for your budget.

2. Installation Costs: If you are considering hiring professionals for the installation, be sure to include the cost of labor in your budget. Installation costs can vary depending on the complexity of the project, the size of the space, and the rates charged by the contractors. Obtaining multiple quotes from reputable installers can help you determine the average cost and select the best option for your needs.

3. DIY vs. Professional Installation: Choosing to do the installation yourself can help save on labor costs, but it is important to assess your skill level and ability to handle the project effectively. Some soundproofing materials, such as acoustic panels, can be relatively easy to install, while others, like resilient channels or window replacements, may require more expertise. Consider your comfort level with DIY projects and weigh it against the potential savings.

4. Additional Costs: Depending on the specific requirements of your soundproofing project, there may be additional costs to consider. This could include the cost of tools and equipment needed for installation, such as drills, screwdrivers, or adhesives. It is important to factor these expenses into your overall budget to ensure you are fully prepared.

Remember that investing in higher-quality soundproofing materials and professional installation, if needed, can provide you with a more effective and long-lasting solution. Carefully consider your budget and priorities when making decisions about the type and thickness of soundproofing materials and the extent of professional help required.

Now that we have discussed the cost considerations, let’s move on to some installation tips to help you get started on your soundproofing project.

Installation Tips

Proper installation is crucial for the effectiveness of soundproofing materials. Here are some tips to help you achieve the best results when installing soundproofing materials:

- Thoroughly assess the space: Before you begin the installation, carefully inspect the space and identify areas that may require special attention. Look for gaps, cracks, or any potential weak points where sound can leak through. Addressing these issues before installing the soundproofing materials will help maximize their effectiveness.

- Follow manufacturer’s instructions: Different soundproofing materials may have specific installation guidelines provided by the manufacturer. Be sure to read and follow these instructions carefully to ensure proper installation. This can include recommendations for adhesive types, installation techniques, and any additional steps required to achieve optimal sound reduction.

- Seal gaps and seams: Use acoustic sealant or caulk to effectively seal any gaps or seams around windows, doors, electrical outlets, or other areas where sound may leak through. This will help create an airtight and soundproof barrier between the interior and exterior spaces.

- Use proper fasteners: When attaching soundproofing materials to surfaces, be sure to use the appropriate fasteners recommended by the manufacturer. This can include screws, nails, or adhesives specifically designed for the type of material being installed. Using the wrong fasteners can compromise the effectiveness of the soundproofing and may cause damage to the underlying structure.

- Consider double-layering: In some cases, using multiple layers of soundproofing materials can provide better results. For example, when soundproofing walls, consider adding an additional layer of drywall with an intermediate layer of mass-loaded vinyl or insulation in between. This will help further dampen sound vibrations and reduce noise transmission.

- Pay attention to corners and edges: Ensure that corners and edges of the soundproofing materials are properly sealed and secured. This will help prevent sound leakage and maintain the overall integrity of the soundproofing system.

- Test and adjust: Once the installation is complete, test the effectiveness of the soundproofing materials by generating noise from outside the treated space. Listen for any noticeable reduction in sound and make adjustments as necessary. This may involve adding additional layers or addressing any remaining gaps or weak points.

Remember, proper installation is essential for achieving the desired level of sound reduction. If you are unsure about the installation process or are dealing with a complex soundproofing project, it is recommended to seek professional assistance to ensure optimal results.

Now that we have explored some installation tips, let’s conclude our article on soundproofing with a summary of the key points we have covered.

Conclusion

Soundproofing plays a vital role in creating a peaceful and comfortable environment by reducing noise pollution. Whether you are dealing with noisy neighbors, a bustling office, or external disturbances, soundproofing materials and techniques can provide effective solutions.

In this article, we have discussed the importance of soundproofing and factors to consider when choosing the right thickness for your soundproofing needs. We explored general thickness recommendations for common applications such as walls, floors, windows, and doors. Additionally, we highlighted common soundproofing materials that can be used to achieve the desired thickness and sound reduction.

We also discussed cost considerations, emphasizing the need to balance budgetary constraints with the importance of investing in high-quality materials and professional installation when necessary. The installation tips provided ensure that soundproofing materials are installed correctly for maximum effectiveness.

Remember, each soundproofing project is unique, and there is no one-size-fits-all approach. It is important to assess your specific needs, budget, and goals when choosing the right thickness and materials for your soundproofing project.

By implementing soundproofing measures, you can create a more peaceful and productive space that enhances your overall well-being and quality of life. So don’t let noise disrupt your environment any longer – take the necessary steps to soundproof your space and enjoy the benefits of a quieter and more serene atmosphere.

Now you are armed with the knowledge and understanding to embark on your soundproofing journey. Good luck and may you find the tranquility you seek!