Home>Devices & Equipment>Turntable>How To Measure A Turntable Belt

Turntable

How To Measure A Turntable Belt

Published: January 17, 2024

Learn how to properly measure a turntable belt with our step-by-step guide. Ensure your turntable functions smoothly with accurate belt measurements.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for AudioLover.com, at no extra cost. Learn more)

Table of Contents

Introduction

Turntables have long been a staple in the world of music, offering a nostalgic and authentic listening experience. However, like any mechanical device, turntables require regular maintenance to ensure optimal performance. One crucial component of a turntable is the belt, which is responsible for driving the platter that spins the vinyl record.

The turntable belt plays a vital role in maintaining the correct speed and accuracy of the platter rotation, directly impacting the quality of sound produced. Over time, the belt may stretch or wear out, leading to issues such as speed variations, skipping, or distorted sound. To keep your turntable in top shape, it is essential to measure the belt periodically to determine if it needs replacement.

In this article, we will delve into the importance of measuring a turntable belt, explore the different methods available for accurate measurement, and provide a step-by-step guide to help you measure your turntable belt properly. We will also highlight common mistakes to avoid during the measuring process, ensuring you obtain accurate results.

Importance of Measuring a Turntable Belt

Measuring a turntable belt may seem like a mundane task, but it holds immense importance in ensuring the optimal performance of your beloved vinyl player. Here are a few reasons why measuring a turntable belt is crucial:

- Accuracy: The turntable belt is responsible for maintaining the accurate speed at which the record spins. Over time, the belt may stretch or wear out, leading to speed inconsistencies. Measuring the belt allows you to identify any deviations and take the necessary steps to ensure precise rotation, preventing issues like pitch variations or the record skipping.

- Sound Quality: A properly tensioned and aligned turntable belt directly impacts the sound quality. If the belt is too loose or damaged, it can cause the stylus to misread the grooves on the record, resulting in distorted or low-quality sound. Measuring the belt ensures that it is in optimal condition, allowing for better tracking and an enjoyable listening experience.

- Longevity: Regularly measuring and replacing the turntable belt when necessary can extend the lifespan of your record player. A worn-out or stretched belt can put unnecessary stress on the motor and other components, potentially leading to further damage. By keeping the belt in good condition, you can increase the longevity of your turntable and minimize the need for costly repairs.

Overall, measuring a turntable belt is an essential maintenance task that directly affects the accuracy, sound quality, and longevity of your vinyl player. It allows you to identify any issues and address them promptly, ensuring that your turntable continues to deliver a superior audio experience.

Methods for Measuring a Turntable Belt

When it comes to measuring a turntable belt, there are a few different methods you can use to ensure accurate results. Let’s explore these methods in detail:

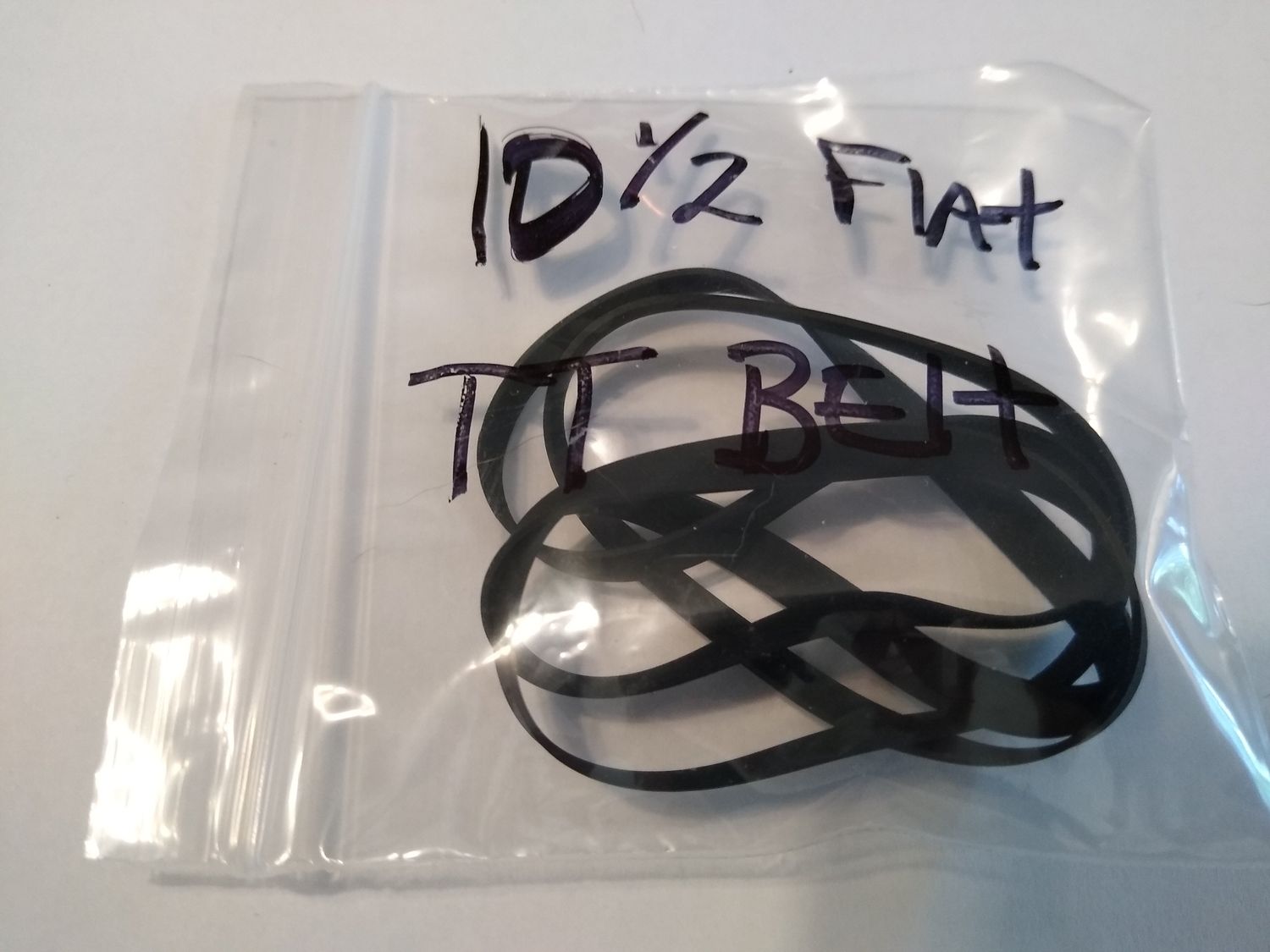

- Visual Inspection: The simplest method to determine if a turntable belt needs replacing is through a visual inspection. Start by removing the platter from your turntable. Look for signs of wear, such as cracks, fraying, or stretching. If the belt appears worn or damaged, it’s a clear indication that it needs to be replaced. While this method can give you a rough estimate, it may not provide precise measurements.

- String Method: The string method is a popular approach for measuring turntable belts. Begin by removing the platter and any obstructions on the turntable. Take a piece of string and wrap it around the path where the belt would normally sit. Make sure the string is taut and mark the point where it overlaps. Measure the length from the starting point to the marked spot, and this will give you an approximate length for your replacement belt.

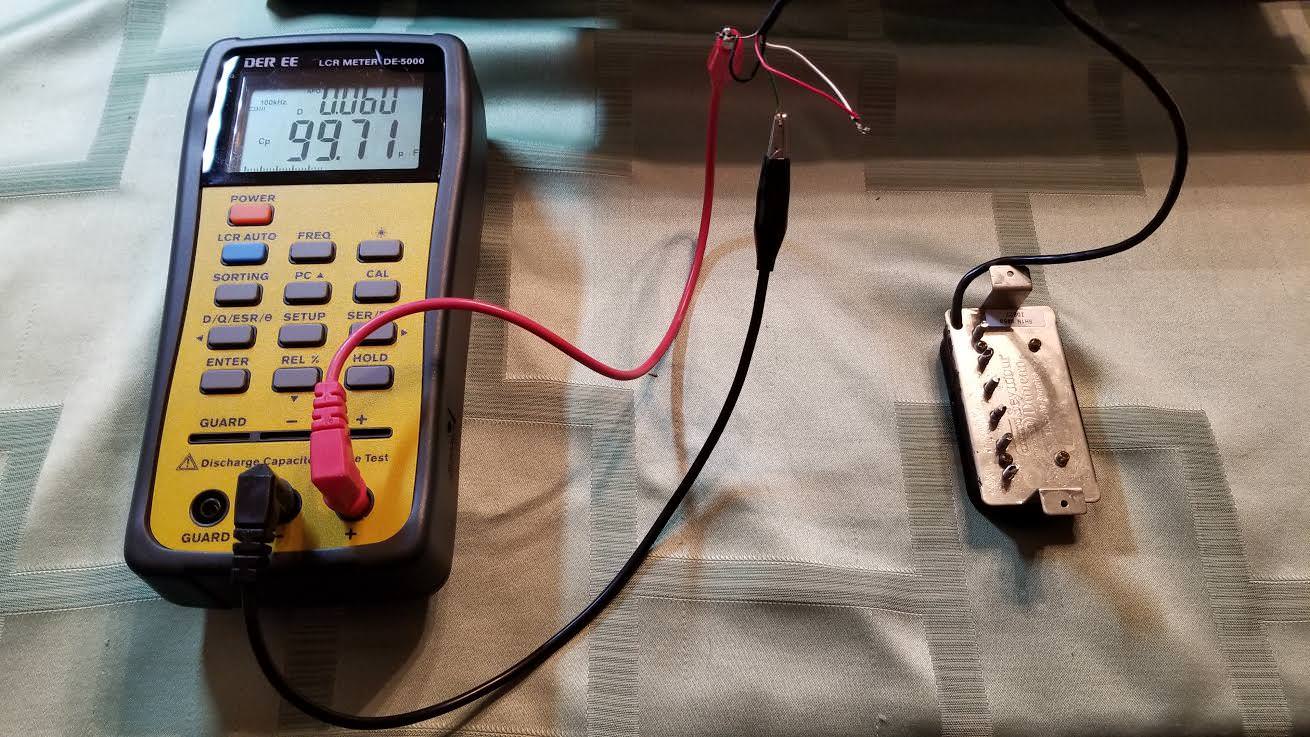

- Turntable Belt Gauge: A more accurate method is to use a turntable belt gauge specifically designed for this purpose. These gauges feature various belt notches that correspond to different turntable models. Simply match the belt against the appropriate notch to determine its size. Turntable belt gauges provide precise measurements and take the guesswork out of finding the correct replacement belt for your specific turntable model.

- Manufacturer’s Specifications: Another reliable method is to consult the manufacturer’s specifications for your turntable model. Check the instruction manual or visit the manufacturer’s website to find the recommended belt length for your specific model. This method ensures you get the exact belt size and guarantees a precise fit for optimal performance.

Remember, different turntables may require different measurement methods. It’s always best to consult the user manual or your turntable manufacturer for the most accurate guidance on how to measure the belt for your specific model.

Step-by-Step Guide to Measuring a Turntable Belt

To accurately measure a turntable belt, follow these step-by-step instructions:

- Prepare Your Workspace: Start by ensuring you have a clean and well-lit workspace to work in. This will help you see the details clearly and prevent any damage to your turntable or belt.

- Turn off and Unplug: Before you begin, make sure your turntable is turned off and unplugged to prevent any accidents or damage during the measuring process.

- Remove the Platter: Carefully remove the platter from your turntable. Depending on your turntable model, this may involve lifting it straight off or loosening screws or clips that hold it in place.

- Clean the Platter and Belt Path: Take this opportunity to clean the platter and the belt path. Use a soft cloth or brush to remove any dust, debris, or grime. Ensure that the belt path is clear and free from any obstructions.

- Inspect the Belt: Before measuring, visually inspect the belt for any signs of damage or wear, such as cracks or fraying. If you notice any significant issues, it’s advisable to replace the belt rather than measuring it.

- Measure the Belt: Depending on the method you choose (visual inspection, string method, turntable belt gauge, or manufacturer’s specifications), follow the appropriate steps to measure the belt accurately. Take your time and ensure you get precise measurements.

- Record the Measurements: Once you have measured the belt, record the measurements for future reference. This will help you when searching for a replacement belt.

- Replace the Platter and Test: After measuring the belt, carefully place the platter back onto your turntable following the manufacturer’s instructions. Ensure that it is securely in place. Plug in and power on your turntable to test the new belt if needed.

Following these step-by-step instructions will help you accurately measure the turntable belt and ensure optimal performance of your vinyl player. Remember to handle all parts with care and consult your turntable manufacturer for any specific instructions related to your model.

Common Mistakes to Avoid When Measuring a Turntable Belt

Measuring a turntable belt may seem like a straightforward task, but there are some common mistakes that people often make. By avoiding these mistakes, you can ensure accurate measurements and prevent potential issues. Here are some common mistakes to avoid when measuring a turntable belt:

- Inaccurate Belt Placement: When measuring the belt, ensure that it is placed in the correct position on the turntable. Improper belt placement can lead to incorrect measurements and may result in a replacement belt that does not fit properly.

- Using a Stretchy Measuring Tape: While it may be tempting to use a stretchy measuring tape, it is not recommended for measuring turntable belts. Stretchy tapes can give inaccurate measurements due to their flexibility. It’s best to use a non-stretchy string or a specialized turntable belt gauge for precise results.

- Not Checking the Belt Tension: A common mistake is not checking the tension of the belt. It should have enough tension to drive the platter properly but not be too tight that it puts unnecessary strain on the motor. For accurate measurements, always ensure the belt is properly tensioned.

- Ignoring Visible Belt Damage: It’s important to address any visible signs of wear or damage on the belt. Neglecting these issues can lead to further problems with your turntable’s performance. If you notice cracked, frayed, or worn sections on the belt, it is advisable to replace it rather than measuring it.

- Failing to Refer to Manufacturer’s Specifications: Each turntable model may have specific belt size requirements. Failing to refer to the manufacturer’s specifications or recommended belt sizes can result in an ill-fitting replacement belt. Always consult the instruction manual or the manufacturer’s website for accurate information on your turntable model.

- Not Double-Checking Measurements: To ensure accuracy, it’s crucial to double-check your measurements before purchasing a replacement belt. Mistakes in measurement can lead to the wrong belt size, resulting in poor performance or potential damage to your turntable.

Taking these precautions and avoiding common mistakes will help you obtain accurate measurements and ensure that you select the right replacement belt for your turntable. If you’re uncertain or uncomfortable with the measuring process, it is recommended to consult a professional or contact the turntable manufacturer for guidance.

Conclusion

Measuring a turntable belt is an essential maintenance task for any vinyl enthusiast. By accurately measuring the belt, you can ensure the optimal performance of your turntable, maintain excellent sound quality, and prolong the lifespan of your beloved vinyl player.

In this article, we have discussed the importance of measuring a turntable belt and explored various methods to achieve precise measurements. Whether you choose the visual inspection, string method, turntable belt gauge, or refer to manufacturer’s specifications, each approach can help you determine if your belt needs replacement.

We have also highlighted common mistakes to avoid when measuring a turntable belt, such as inaccurate belt placement, using a stretchy measuring tape, neglecting visible belt damage, and not referring to manufacturer’s specifications. By steering clear of these errors, you can ensure accurate measurements and select the correct replacement belt for your turntable.

Regular maintenance, including measuring and replacing the turntable belt when needed, is crucial for preserving the accuracy, sound quality, and longevity of your vinyl player. So, take the time to perform this simple yet vital task and enjoy the best possible listening experience.

Remember, if you ever feel uncertain or uncomfortable with the measuring process, it is always advisable to seek professional guidance or contact the turntable manufacturer for assistance. With proper measurement and maintenance, your turntable will continue to provide countless hours of joy and musical pleasure.