Home>Production & Technology>Audiophile>How To Make Audiophile Capacitors

Audiophile

How To Make Audiophile Capacitors

Modified: February 18, 2024

Learn how to make audiophile capacitors and elevate your sound quality to new heights. Enhance your audio experience with our step-by-step guide.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for AudioLover.com, at no extra cost. Learn more)

Table of Contents

Introduction

When it comes to the world of audiophiles, every component of a sound system is crucial in achieving the ultimate audio experience. One key element that often gets overlooked is the capacitor. Audiophile capacitors play a critical role in the overall sound quality by storing and releasing electrical energy in a precise and controlled manner.

In this article, we will delve into the fascinating world of audiophile capacitors and explore the process of making your own. Whether you are a seasoned DIY enthusiast looking to enhance your audio setup or a curious newcomer eager to learn more about this aspect of the audiophile world, this guide will provide you with valuable insights and practical advice.

Understanding the intricacies of audiophile capacitors is essential before diving into the process of making them. These specialized capacitors differ from standard capacitors in terms of materials, construction, and performance. They are designed to have lower tolerance, lower ESR (Equivalent Series Resistance), and higher voltage ratings, allowing for improved audio signal transmission and sound reproduction.

While there are many high-quality audiophile capacitors available in the market, making your own gives you the opportunity to tailor the capacitor to your specific needs and preferences. Plus, it can be a rewarding and satisfying experience to create a custom component for your audio system.

In the next sections, we will discuss the different types of audiophile capacitors, guide you through the selection process, outline the required materials, walk you through the steps of making your own capacitors, and provide tips for testing and fine-tuning their performance.

So, let’s embark on this journey into the realm of audiophile capacitors and discover how these tiny yet mighty components can elevate your audio experience to new heights!

Understanding Audiophile Capacitors

Before diving into the process of making audiophile capacitors, it’s essential to have a solid understanding of their purpose and how they impact sound quality. Audiophile capacitors are specially designed to contribute to a cleaner and more accurate reproduction of audio signals in a high-end audio system.

One crucial factor that sets audiophile capacitors apart from their standard counterparts is the quality of their construction. These capacitors are built using high-grade materials and advanced manufacturing techniques to ensure optimal performance. They often feature low tolerances, meaning they have minimal variation in their stated capacitance value.

Additionally, audiophile capacitors have lower ESR (Equivalent Series Resistance), which is the inherent resistance present in a capacitor. Lower ESR helps maintain a higher level of energy transfer between the capacitor and the audio signal, resulting in improved clarity and detail in the sound reproduction.

Audiophile capacitors also boast higher voltage ratings, allowing them to handle higher voltages without compromising their performance. This is crucial in audio systems where higher voltage levels are common, as it prevents the capacitors from distorting or affecting the sound in any undesirable way.

Furthermore, the dielectric material used in audiophile capacitors plays a significant role in their performance. Dielectric materials, such as polypropylene, polystyrene, or foil, are carefully chosen for their excellent insulation properties and minimal distortion. These materials effectively store and release electrical energy, resulting in cleaner and more accurate audio signal transmission.

It’s worth noting that the influence of audiophile capacitors on sound quality can vary depending on the specific components and circuitry of an audio system. However, in general, upgrading to high-quality audiophile capacitors can lead to improvements in tonal accuracy, extended frequency response, enhanced dynamics, and a more immersive listening experience.

Now that we have a better understanding of audiophile capacitors and their significance in the audio world, let’s proceed to the next section, where we will explore how to select the right type of capacitor for your DIY project.

Selecting the Right Capacitor Type

Choosing the right type of capacitor is crucial when it comes to making audiophile capacitors. The capacitor type you select will impact the overall performance and sound quality of your DIY project. Here are some factors to consider when selecting the right capacitor type:

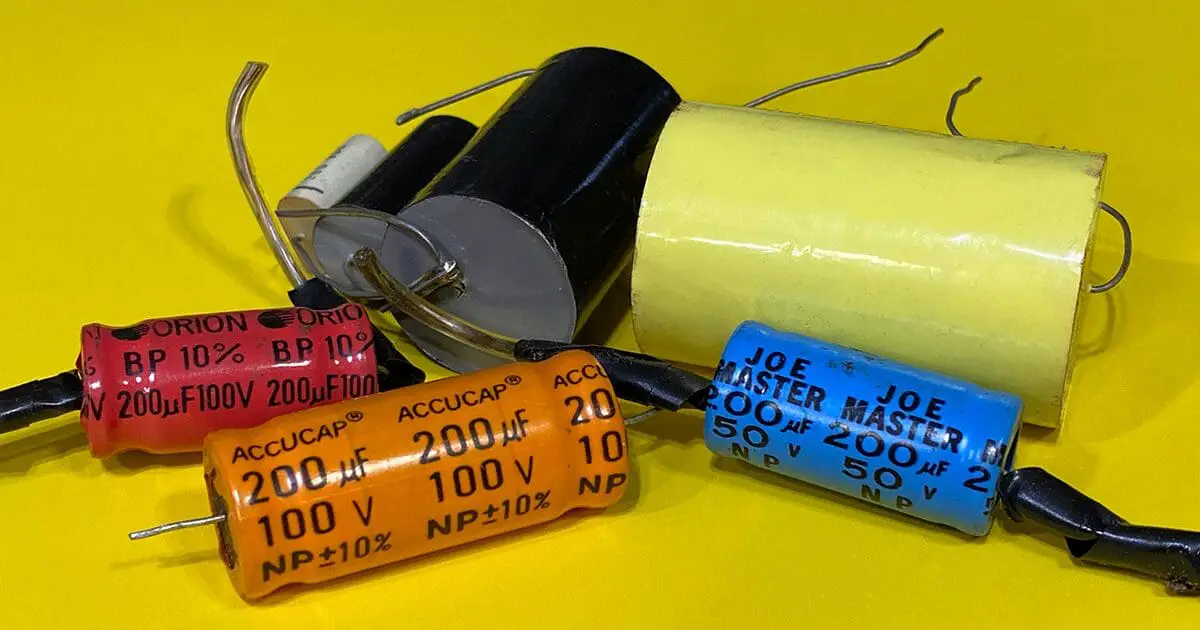

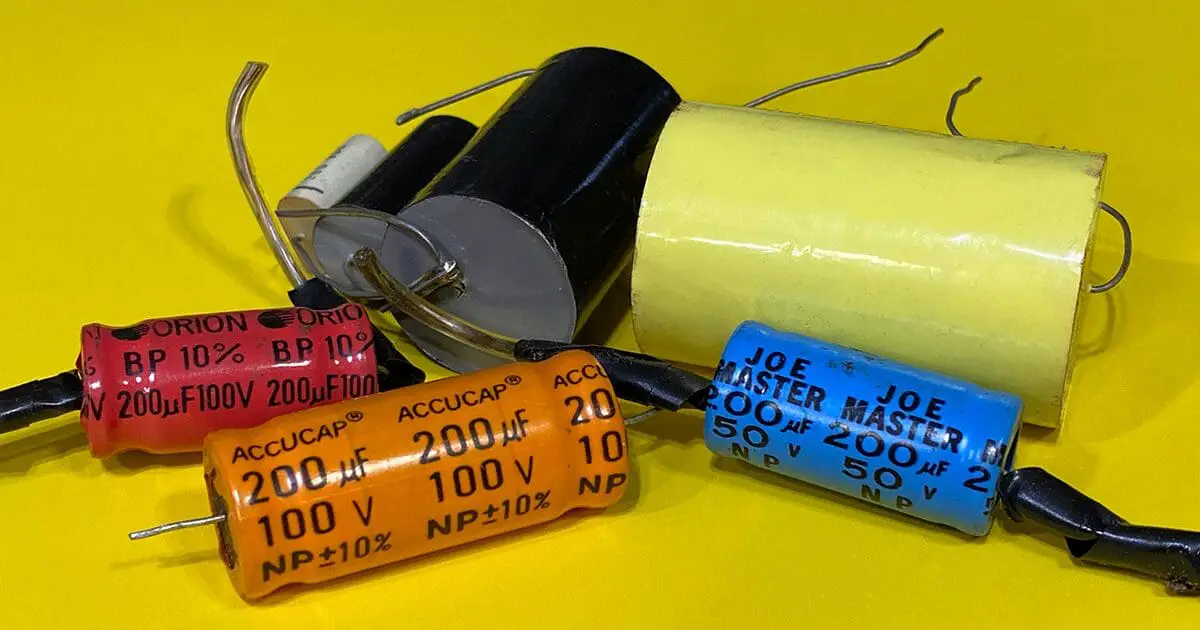

- Dielectric Material: The dielectric material used in a capacitor determines its electrical properties and sound characteristics. Common dielectric materials for audiophile capacitors include polypropylene, polystyrene, and foil. Each material has its own sonic signature, so it’s essential to consider the tonal qualities you desire for your audio system.

- Capacitance Value: The capacitance value of a capacitor determines how much charge it can store. It’s important to choose a capacitor with an appropriate capacitance value for your specific application. Higher capacitance values generally offer better bass response, while lower capacitance values can improve detail and clarity.

- Voltage Rating: Ensure that the capacitor you choose has a voltage rating that matches or exceeds the requirements of your audio system. This ensures that the capacitor can handle the voltage levels without damaging or distorting the audio signal.

- Tolerance Rating: The tolerance rating indicates the acceptable variation in the stated capacitance value. For accurate sound reproduction, it’s advisable to select capacitors with low tolerances to minimize any discrepancies in the capacitor’s actual capacitance.

- Physical Size: Consider the physical size of the capacitor as it should fit comfortably within your audio system or enclosure. Additionally, smaller capacitors tend to have lower parasitic inductance and resistance, which can positively impact their performance.

It’s worth noting that different capacitor types excel in specific areas of sound reproduction. For example, polypropylene capacitors are known for their excellent linearity and low distortion, making them well-suited for audio applications. On the other hand, polystyrene capacitors are highly regarded for their accuracy and high-frequency response. Foil capacitors, while more expensive, offer exceptional signal transparency and are a favorite among audiophiles.

Ultimately, the selection of the right capacitor type will depend on your personal preferences, budget, and the specific sound characteristics you aim to achieve in your audio system. It may be helpful to consult with audio enthusiasts or experts for recommendations based on your specific requirements.

Now that you have a better understanding of the factors to consider when selecting the right capacitor type, let’s move on to the next section where we will discuss the materials you’ll need to make your own audiophile capacitors.

Gathering the Required Materials

To embark on the journey of making your own audiophile capacitors, you will need to gather a few essential materials. These materials will ensure that you have everything you need to create high-quality capacitors tailored to your specific audio system. Here is a list of the necessary materials:

- Capacitor Casings: You will need suitable casings to house your homemade capacitors. You can choose from various options, such as plastic or metal casings, depending on your preference and the desired aesthetics.

- Lead Wires: Lead wires are crucial for connecting the capacitor plates to the casing. Use high-quality wires that provide good electrical conductivity and are long enough to reach the capacitor plates while fitting comfortably into the casing.

- Capacitor Plates: The capacitor plates are the most vital component of your audiophile capacitors. You can purchase pre-made capacitor plates or make them yourself using high-quality conductive materials such as aluminum foil or copper sheets. Ensure that the plates are cut to the appropriate dimensions for the desired capacitance value.

- Dielectric Material: Select the desired dielectric material based on your preferences and the sonic characteristics you want to achieve. Polypropylene and polystyrene sheets are commonly used dielectric materials. These can be purchased from electronics suppliers or repurposed from other sources.

- Soldering Equipment: Soldering equipment, including a soldering iron, solder, and flux, is necessary for connecting the lead wires to the capacitor plates. Ensure that you have a reliable and precise soldering iron to achieve strong and clean connections.

- Insulating Material: To prevent any unwanted electrical contact or short circuits, you will need insulating materials such as heat shrink tubing or insulating tape. These materials will be used to cover and protect the soldered connections and ensure proper insulation.

- Multimeter: A multimeter is a valuable tool for testing the capacitance value, voltage rating, and other electrical parameters of your homemade capacitors. It will help in ensuring the accuracy and performance of your capacitors.

It’s important to note that the specific materials you choose will depend on your budget, availability, and desired level of customization. You may also want to consider additional accessories like mounting brackets, terminal blocks, or labeling materials to further enhance the functionality and appearance of your capacitors.

Now that you have a comprehensive list of the essential materials needed for making your own audiophile capacitors, let’s move on to the next section where we will dive into the step-by-step process of creating these capacitors.

Steps for Making Audiophile Capacitors

Now that you have gathered all the necessary materials, it’s time to dive into the process of making your own audiophile capacitors. Follow these step-by-step instructions to create custom capacitors that will enhance the audio quality of your system:

- Prepare the Capacitor Casings: Start by preparing the capacitor casings. Ensure they are clean and free from any debris. If necessary, drill holes for the lead wires to pass through.

- Create the Capacitor Plates: Cut the desired size and shape of the capacitor plates from high-quality conductive material, such as aluminum foil or copper sheets. Ensure that the plates fit comfortably inside the casing and do not touch each other.

- Apply the Dielectric Material: Place the dielectric material, such as polypropylene or polystyrene sheets, between the capacitor plates. Cut them to match the dimensions of the plates. The dielectric material will prevent direct contact between the plates and allow for proper energy storage and release.

- Solder the Lead Wires: Strip the insulation from the ends of the lead wires and solder them to the capacitor plates. Ensure a secure and strong connection, and trim any excess wire. Be careful not to apply excessive heat that could damage the dielectric material.

- Insulate the Connections: Use insulating materials, such as heat shrink tubing or insulating tape, to cover the soldered connections. This will prevent any short circuits or electrical contact with the capacitor casing.

- Secure the Capacitor Plates: Place the assembled capacitor plates with the dielectric material into the casing. Ensure that they are properly aligned and securely positioned.

- Close the Casing: Carefully close the capacitor casing, ensuring that all components are properly aligned and fit together securely. Double-check that the lead wires protrude through the designated holes in the casing.

- Test the Capacitor: Use a multimeter to test the capacitance value and voltage rating of the homemade capacitor. Compare the results with your desired specifications, and make any necessary adjustments if needed.

It’s important to note that this is a general outline of the steps involved in making audiophile capacitors. The specific details may vary depending on the materials and components you choose. It’s recommended to refer to manufacturer instructions or seek guidance from experienced DIY audiophiles for more precise instructions related to your specific materials and desired capacitors.

Now that you have successfully created your own audiophile capacitors, it’s time to move on to the final section to ensure their performance is optimized and fine-tuned for your audio system.

Testing and Fine-tuning Capacitor Performance

Once you have completed the process of making your own audiophile capacitors, it’s crucial to test and fine-tune their performance to ensure optimal results in your audio system. Here are some steps to help you in this process:

- Verify Capacitance Value: Use a multimeter or a dedicated capacitance tester to verify the capacitance value of your homemade capacitors. Compare the measured value with your desired specifications to ensure accuracy. If there are any significant deviations, you may need to adjust the size or positioning of the capacitor plates.

- Check Voltage Rating: Confirm that the voltage rating of the capacitors matches or exceeds the requirements of your audio system. It’s essential to ensure the capacitors can handle the voltage levels without distorting or affecting the audio signal.

- Integrate into Audio System: Install the homemade capacitors into your audio system following the applicable guidelines. Ensure proper electrical connections and secure placement within the circuitry.

- Listen and Analyze: Listen to your audio system with the newly installed capacitors. Pay attention to any noticeable changes in sound quality, such as improved clarity, enhanced dynamics, or extended frequency response. Take note of any areas that might still require fine-tuning.

- Experiment with Different Capacitor Types: If you’re not fully satisfied with the initial results, consider experimenting with different capacitor types or dielectric materials. Each type can have a unique impact on the sound characteristics. You can swap out capacitors and listen to the changes they bring to determine the best fit for your audio system.

- Fine-tune Capacitor Placement: Explore different placements within the audio system to find the optimal location for your homemade capacitors. They can be installed near sensitive circuit components or in specific sections of the signal path for maximum impact.

- Consider Parallel or Series Configurations: Experiment with different capacitor configurations, such as parallel or series setups, to further refine the sound. These configurations can alter the capacitance value and electrical properties, leading to different sonic characteristics.

- Seek Expert Opinions: If you’re still unsure about the performance of your homemade capacitors or want additional guidance, consider seeking advice from experienced audiophiles or consulting with audio professionals. They can share their insights and suggest further improvements based on their expertise.

Remember that fine-tuning the performance of capacitors in your audio system is an ongoing process. Take your time to listen and analyze the results, making adjustments as necessary to achieve the desired sound quality and overall audio experience.

Now that you have tested and fine-tuned the performance of your homemade audiophile capacitors, you can enjoy the enhanced audio quality and personalized touch they bring to your system.

Conclusion

Congratulations on completing your journey into the world of audiophile capacitors! By making your own custom capacitors, you have taken a significant step towards enhancing the sound quality and overall performance of your audio system. Through understanding the importance of audiophile capacitors, selecting the right capacitor type, gathering the necessary materials, following the steps for creating your own capacitors, and testing and fine-tuning their performance, you have gained valuable insights and hands-on experience in this specialized field.

Audiophile capacitors play a crucial role in achieving a cleaner, more accurate audio reproduction. Their low tolerance, low ESR, and high voltage ratings contribute to improved signal transmission and superior sound quality. By creating your own capacitors, you have the opportunity to tailor their characteristics to meet your specific audio preferences and needs.

Remember, the journey doesn’t end with the completion of your homemade capacitors. Continuously exploring different configurations, experimenting with dielectric materials, and seeking expert opinions will enable you to further fine-tune the performance and achieve the desired sonic characteristics in your audio system.

Whether you’re a seasoned DIY enthusiast or a curious newcomer, the process of making audiophile capacitors opens up a world of possibilities. It provides a deeper understanding of the components that shape audio quality and empowers you to personalize your audio setup to suit your tastes.

So, unleash your creativity, engage in meticulous craftsmanship, and discover the immense satisfaction of enjoying audio that is truly tailored to your discerning ear. With a little patience, experimentation, and knowledge, you can elevate your audio experience to new heights with your very own audiophile capacitors.