Home>Devices & Equipment>Subwoofer>How To Fix A Subwoofer Cone

Subwoofer

How To Fix A Subwoofer Cone

Modified: February 18, 2024

Learn how to fix a subwoofer cone and get your speakers back to sounding their best with these simple steps. Avoid the need for costly repairs and keep enjoying your favorite tunes.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for AudioLover.com, at no extra cost. Learn more)

Table of Contents

Introduction

Subwoofers are an essential component of any audio system, adding depth and richness to the lower frequencies. However, just like any other mechanical device, subwoofers can experience issues over time. One common problem that subwoofer owners may encounter is a damaged or faulty cone.

The subwoofer cone plays a critical role in reproducing low-frequency sound waves accurately. It is responsible for moving air and generating the bass that adds impact and realism to music and movies. When the cone becomes damaged, it can affect the overall performance and sound quality of the subwoofer.

In this article, we will guide you through the process of fixing a subwoofer cone. Whether it’s a tear, a dent, or any other type of damage, we will provide you with the tools and knowledge necessary to restore your subwoofer to its optimal functionality.

Before we dive into the details of fixing a subwoofer cone, it is important to note that some issues may require professional repair. If you are unsure about your abilities or if your subwoofer is still under warranty, it’s best to consult a qualified technician or the manufacturer for assistance.

Now, let’s explore the various aspects of subwoofer cones and how to identify and address common cone issues.

Understanding Subwoofer Cones

Subwoofer cones are typically made from materials such as paper, polypropylene, or aluminum. These materials are selected for their rigidity, lightness, and ability to withstand the demands of low-frequency sound reproduction.

The cone is the part of the subwoofer that moves back and forth to create sound waves. It is attached to the voice coil, which is responsible for converting electrical signals into mechanical vibrations. When the voice coil receives electrical current, it causes the cone to move, pushing air and producing sound waves.

The size and design of the cone also play a crucial role in subwoofer performance. Larger cones can move more air, resulting in deeper bass response. Cone designs can vary, with some featuring a rigid flat surface, while others have a more flexible curved shape. These design variations affect the way the cone responds to different frequencies and can impact the overall sound accuracy and clarity.

Subwoofer cones are generally built to be durable and withstand regular usage. However, over time, wear and tear can occur, leading to issues such as tears, dents, or even complete cone failure. Additionally, exposure to extreme temperatures, moisture, or physical mishandling can also cause cone damage.

It’s important to note that not all cone damage is visible from the exterior. Sometimes, the damage can be internal, resulting in distortion or abnormal sound reproduction.

Now that we have a basic understanding of subwoofer cones, let’s move on to how to identify cone issues and determine if they can be fixed.

Identifying Subwoofer Cone Issues

Identifying subwoofer cone issues is the first step towards finding a solution. Here are some common signs that your subwoofer cone might be damaged:

- Visible Tears or Holes: Inspect the cone for any visible tears or holes. These can occur from mishandling, sharp objects, or excessive power.

- Inconsistent Bass Performance: If you notice a sudden decrease in bass output or if the bass sounds distorted or muffled, it could indicate a problem with the cone.

- Cracking Sounds: If you hear cracking or popping noises from the subwoofer, it might be due to a damaged cone.

- Uneven Movement: Watch the subwoofer cone while it’s playing. If the cone moves unevenly or wobbles, it could be a sign of cone damage.

- Abnormal Vibrations: Excessive vibrations that weren’t present before could indicate an issue with the cone’s alignment or structural integrity.

It’s important to note that not all cone issues can be fixed. If the damage is extensive or if the cone material is severely compromised, it may be necessary to replace the entire cone or consider professional repair options.

However, if the damage is minimal and doesn’t affect the overall functionality of the subwoofer, it may be possible to fix it yourself. The next section will outline the tools and materials you’ll need for the repair process.

Tools and Materials Needed

Before you begin repairing your subwoofer cone, make sure you have the following tools and materials ready:

- Replacement Cone or Repair Kit: Depending on the extent of the damage, you may need a new cone or a repair kit that includes adhesive, reinforcement materials, and a cone template.

- Screwdriver Set: A set of screwdrivers will be necessary to remove the subwoofer from its enclosure and access the cone.

- Tweezers or Pliers: These will come in handy for handling small components during the repair process.

- Epoxy Adhesive: High-quality epoxy adhesive is essential to securely attach the replacement cone or repair any tears in the existing cone.

- Sandpaper: Fine-grit sandpaper (around 200-400 grit) will be needed to smooth out any rough areas on the cone surface before applying adhesive.

- Cleaning Solution: A mild cleaning solution and a soft cloth will be useful for cleaning the cone and removing any dirt or debris.

- Protective Gloves: It’s always a good idea to protect your hands with gloves to avoid any potential injury or exposure to adhesives.

It’s important to ensure that you have all the necessary tools and materials before starting the repair process. This will make the process smoother and minimize any interruptions or delays.

Now that you have the required tools and materials, let’s move on to the step-by-step guide on fixing a subwoofer cone.

Step-by-Step Guide: Fixing a Subwoofer Cone

Follow these steps to repair a damaged subwoofer cone:

- Disconnect the Subwoofer: Before you begin any repairs, ensure that the subwoofer is disconnected from the power source and any audio sources.

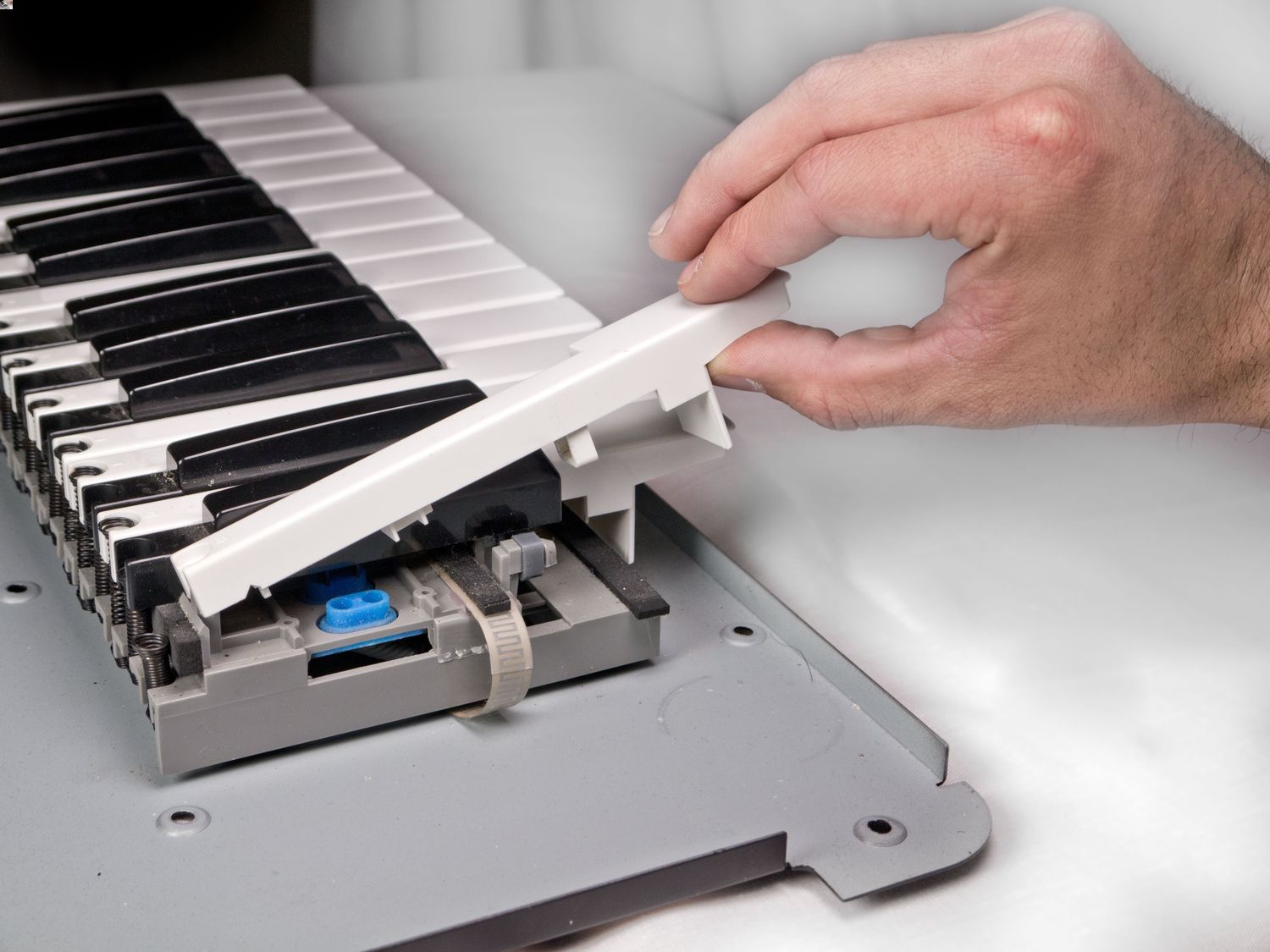

- Remove the Subwoofer from its Enclosure: Use a screwdriver to remove any screws or fasteners holding the subwoofer in place. Carefully detach the subwoofer from its enclosure.

- Inspect the Damage: Assess the extent of the damage on the subwoofer cone. If it is a minor tear or hole, you may be able to repair it. If the cone is severely damaged, it may need to be replaced entirely.

- Clean the Cone: Use a mild cleaning solution and a soft cloth to clean the cone surface and remove any debris or dirt. This will ensure proper adhesion when repairing the cone.

- Repair the Cone: If the damage is small, you can repair it with a patch or repair kit. Follow the manufacturer’s instructions to apply adhesive and reinforcement materials to the damaged area. Apply pressure and let it cure according to the instructions.

- Replace the Cone: If the damage is extensive or the repair is not possible, you will need to replace the entire cone. Ensure that the replacement cone is compatible with your subwoofer model.

- Attach the Replacement Cone: Apply an epoxy adhesive to the cone edges and carefully place the replacement cone in position. Apply pressure to ensure a secure bond.

- Let the Adhesive Cure: Allow sufficient time for the adhesive to fully cure according to the manufacturer’s instructions. This will ensure a strong and durable bond.

- Reassemble the Subwoofer: Once the adhesive has cured, reattach the subwoofer to its enclosure using the screws or fasteners removed earlier. Ensure it is securely in place.

- Test the Subwoofer: Reconnect the subwoofer to the power source and audio sources. Test the subwoofer to ensure that it is functioning properly and the repaired cone is producing the desired sound.

Remember, it’s crucial to follow the manufacturer’s instructions and take necessary precautions throughout the repair process. If you are unsure about any step or encounter difficulties, it is recommended to consult a professional technician or the manufacturer for guidance.

With these steps, you should be able to repair or replace a damaged subwoofer cone and restore the performance of your subwoofer.

Conclusion

Repairing a damaged subwoofer cone can save you the cost of buying a new subwoofer or seeking professional repair services. By following the step-by-step guide provided in this article, you can effectively address common cone issues and restore the optimal functionality of your subwoofer.

Remember, it’s essential to properly identify the cone issue and determine if it can be fixed before attempting any repairs. If the damage is extensive or beyond your capabilities, it’s always wise to consult a professional or reach out to the manufacturer for assistance.

Having the necessary tools and materials, along with careful execution of the repair process, is crucial for a successful repair job. Take your time, follow the instructions, and exercise caution throughout the entire process to avoid any further damage or accidents.

Ultimately, the goal is to have a fully functioning subwoofer that reproduces deep and impactful bass for your audio system. By addressing cone issues promptly and effectively, you can continue to enjoy your favorite music, movies, and immersive audio experiences.

Always remember to prioritize your safety and consult experts if you are unsure about any aspect of the repair process. With determination and the right tools, you can extend the lifespan of your subwoofer and get back to enjoying the thrilling low-frequency sounds that enrich your audio system.